Water-based metal ink for UV offset ink and preparation method thereof

A metal ink and offset printing ink technology, applied in the field of printing ink, can solve the problems of slow drying, non-alkali resistance, paper shrinkage, etc., and achieve the effect of simple preparation process, no irritating smell, safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

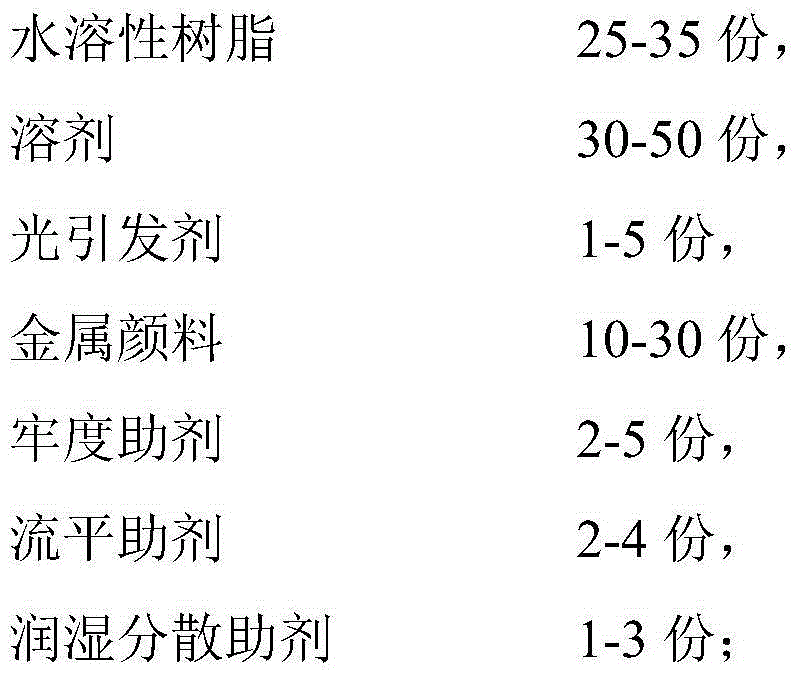

Method used

Image

Examples

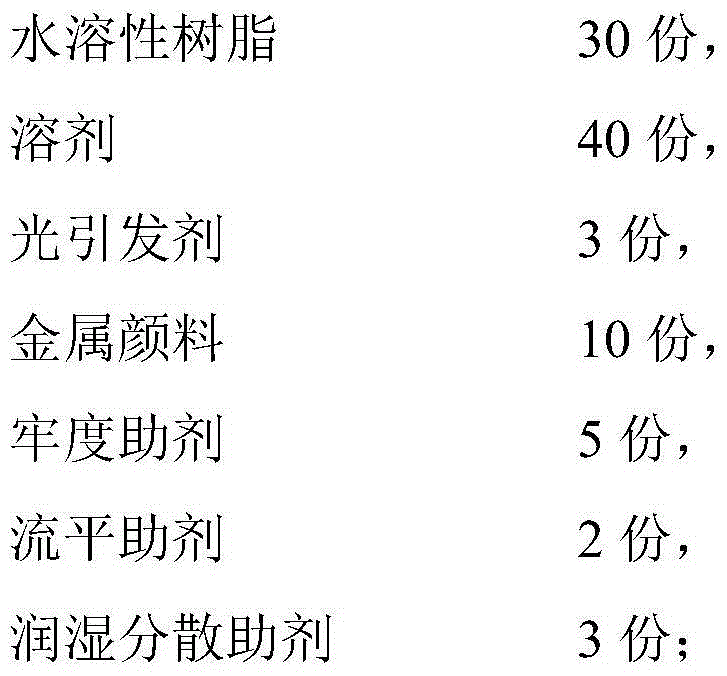

Embodiment 1

[0033] The present embodiment is used for the water-based metallic ink of UV offset printing ink, comprises following component and weight portion content: 30 parts of water-soluble resins, 40 parts of solvents, 3 parts of photoinitiators, 10 parts of metal pigments, 5 parts of fastness assistants, 2 parts of leveling aid and 3 parts of wetting and dispersing aid.

[0034] Wherein, the solvent is a mixed solvent of deionized water and ethanol with a mass ratio of 1:1; the metal pigment is copper gold powder, the particle size of the copper gold powder is 11 μm, and the sieve residue content is lower than 0.5%; the water-soluble resin has a solid content of 60% urethane resin, the viscosity is 40s; the photoinitiator is 1-hydroxyphenylcyclohexanone; the fastness additive is γ-aminopropyltriethoxysilane; the leveling additive is polyether modified Polydimethylsiloxane and polyacrylate mixed leveling aid with a mass ratio of 1:1; the wetting and dispersing additive is polyacrylat...

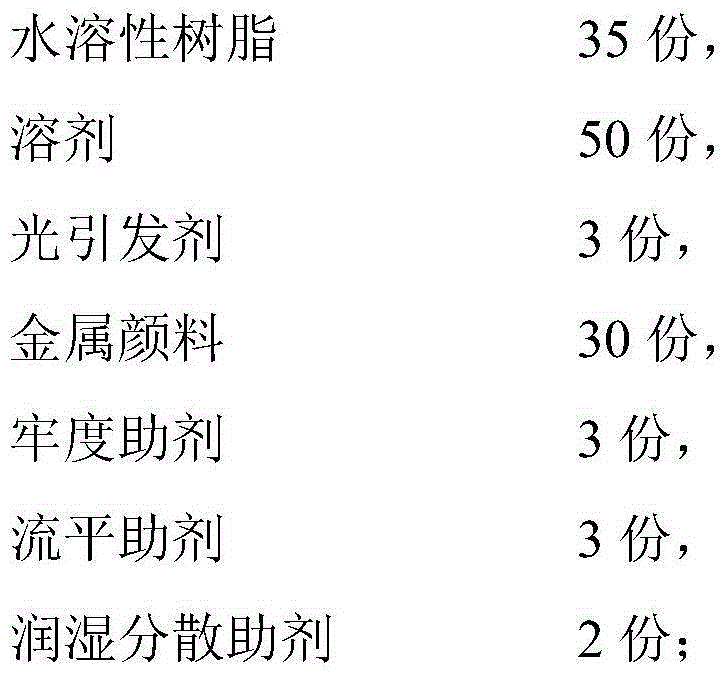

Embodiment 2

[0042] The present embodiment is used for the water-based metallic ink of UV offset printing ink, comprises following component and weight portion content: 35 parts of water-soluble resins, 50 parts of solvents, 3 parts of photoinitiators, 30 parts of metallic pigments, 3 parts of fastness assistants, 3 parts of leveling aid and 2 parts of wetting and dispersing aid.

[0043] Wherein, the solvent is a mixed solvent of deionized water and ethanol with a mass ratio of 1:1; the metal pigment is copper gold powder, the particle size of the copper gold powder is 13 μm, and the sieve residue content is lower than 0.5%; the water-soluble resin has a solid content of 55% maleic acid resin, viscosity is 30s; photoinitiator is 2-hydroxy-2-methyl-1-phenyl-1-propanone; fastness aid is triethoxymethylsilane; leveling aid It is a leveling aid mixed with polyether modified polydimethylsiloxane and polyacrylate at a mass ratio of 1:2; the wetting and dispersing aid is polyethylene glycol.

...

Embodiment 3

[0051] The present embodiment is used for the water-based metal ink of UV offset printing ink, comprises following component and weight portion content: 32 parts of water-soluble resins, 45 parts of solvents, 2 parts of photoinitiators, 25 parts of metallic pigments, 2 parts of fastness assistants, 2 parts of leveling aid and 1 part of wetting and dispersing aid.

[0052] Wherein, the solvent is a mixed solvent of deionized water and ethanol with a mass ratio of 1:1; the metal pigment is copper gold powder, the particle size of the copper gold powder is 12 μm, and the sieve residue content is lower than 0.5%; the water-soluble resin has a solid content of 57% maleic acid resin with a viscosity of 30s; the photoinitiator is 2,4,6-trimethylbenzoyl-diphenylphosphine oxide; the fastness additives are vinyl triethoxy silicon and triethyl Oxymethylsilane is a mixed fastness aid with a mass ratio of 1:2; the leveling aid is a mixed leveling aid of polyether-modified polydimethylsilox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com