Anti-electromagnetic radiation fabric coating adhesive and preparation method thereof

A technology of anti-electromagnetic radiation and coating glue, which is applied in the field of pure cotton and polyester fabrics, can solve the problems of high production requirements, harsh reaction conditions, and many index performances, and achieve short production process, strong charge storage capacity, and high conductivity. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

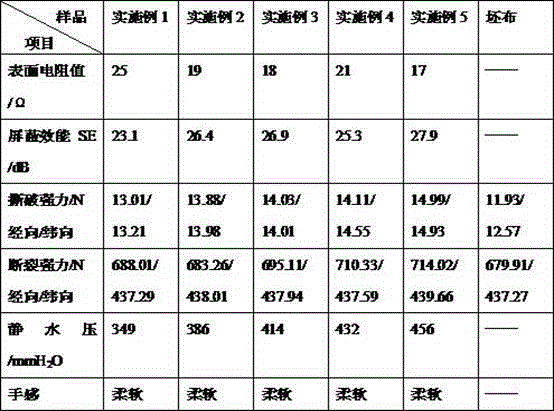

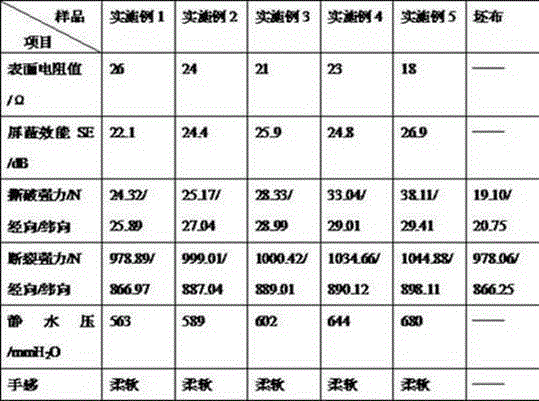

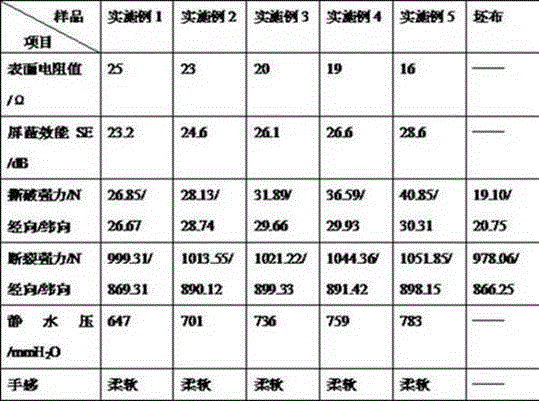

Examples

Embodiment 1

[0047] Raw material weight ratio: sodium dodecylbenzenesulfonate 8.0, fatty alcohol polyoxyethylene ether 5.0, butyl acrylate 25, isooctyl acrylate 85, cyclohexyl methacrylate 9.0, acrylamide 3.5, acrylic acid 4.0, trihydroxy Methyl propane triacrylate 1.5, styrene 10, glycidyl methacrylate 1.5, ammonium persulfate 1.0, deionized water 250; conductive polyaniline 3, N,N-dimethylformamide 15, carbon nanotubes Dispersion 30, associative polyurethane leveling rheological agent 3

[0048] 1) Emulsification reaction: add sodium dodecylbenzenesulfonate 8.0, fatty alcohol polyoxyethylene ether 5.0, and deionized water 215 to the pre-milk tank, mix thoroughly, add isooctyl acrylate 85, butyl acrylate 25 , cyclohexyl methacrylate 9.0, acrylamide 3.5, acrylic acid 4.0, trimethylolpropane triacrylate 1.5, styrene 10.0, glycidyl methacrylate 1.5, stirring and emulsifying for 30-35 minutes to make an emulsion ;

[0049] 2) Initiate polymerization reaction: Take 25% of the total we...

Embodiment 2

[0053] Raw material weight ratio: sodium dodecylbenzenesulfonate 8.5, fatty alcohol polyoxyethylene ether 5.5, isooctyl acrylate 86, butyl acrylate 26, cyclohexyl methacrylate 9.2, acrylamide 3.6, acrylic acid 4.2, Trimethylolpropane triacrylate 1.6, styrene 12, glycidyl methacrylate 1.6, ammonium persulfate 1.2, deionized water 276; conductive polyaniline 4, N,N-dimethylformamide 15, carbon Nanotube dispersion 30.9, associative polyurethane leveling rheological agent 3.1; production process is the same as in Example 1.

Embodiment 3

[0055] Raw material weight ratio: sodium dodecylbenzenesulfonate 8.8, fatty alcohol polyoxyethylene ether 5.6, isooctyl acrylate 87, butyl acrylate 27, cyclohexyl methacrylate 9.4, acrylamide 3.7, acrylic acid 4.3, three Methylol propane triacrylate 1.7, styrene 14, glycidyl methacrylate 1.7, ammonium persulfate 1.4, deionized water 300; conductive polyaniline 4.5, N,N-dimethylformamide 15, carbon nano Tube dispersion 32.1, associative polyurethane leveling rheology agent 3.2; production process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com