Activation method before flexible backing material chemical plating based on numerator self-assembly technique

A self-assembly technology and flexible substrate technology, which is applied in the field of activation of flexible substrates before electroless plating, to achieve the effects of cost reduction, good bonding fastness, and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

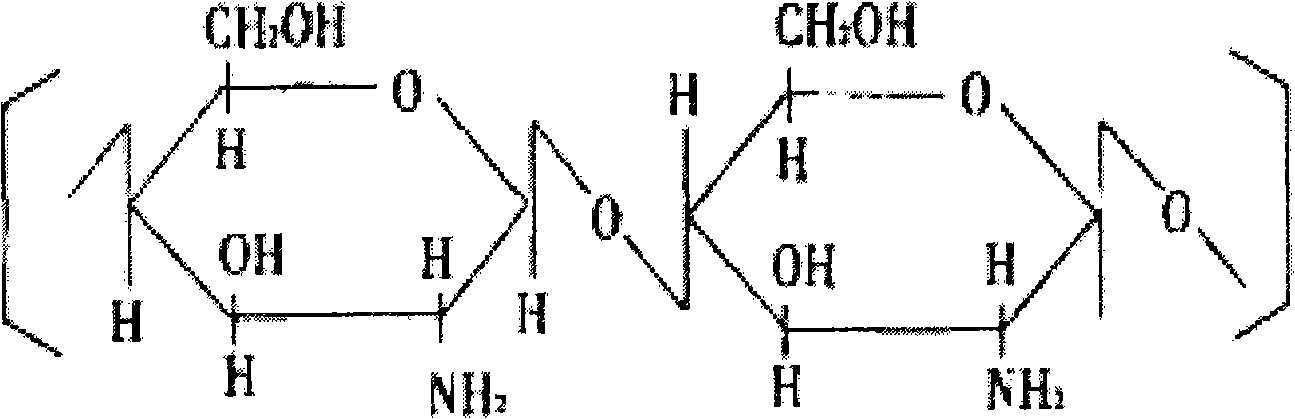

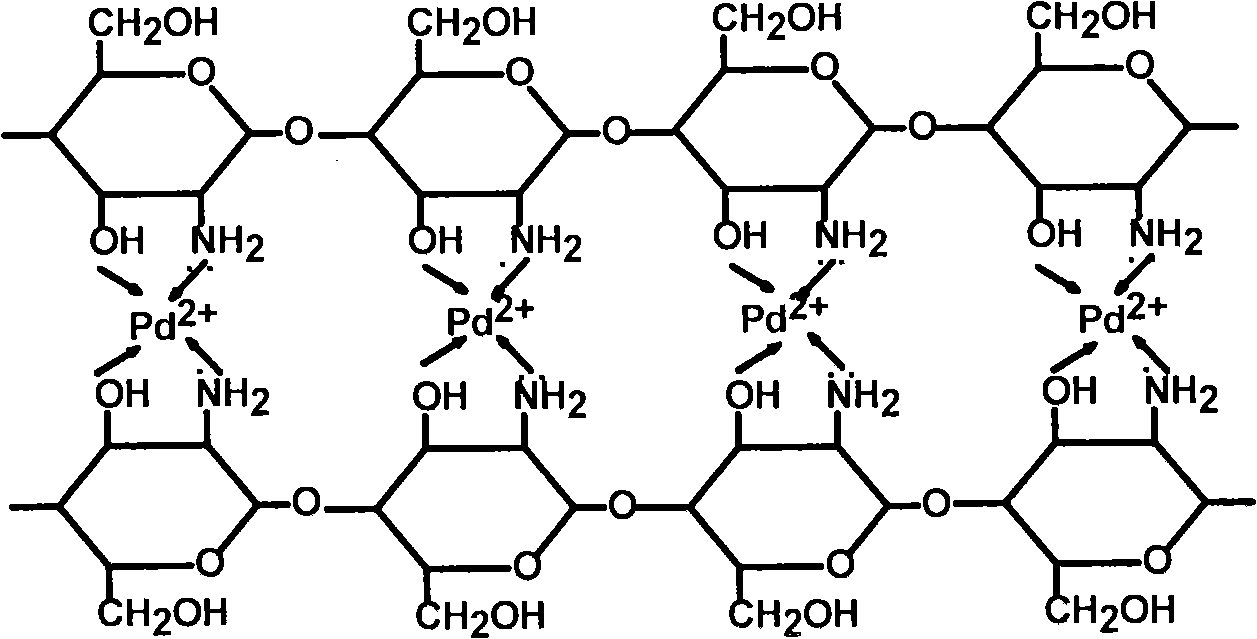

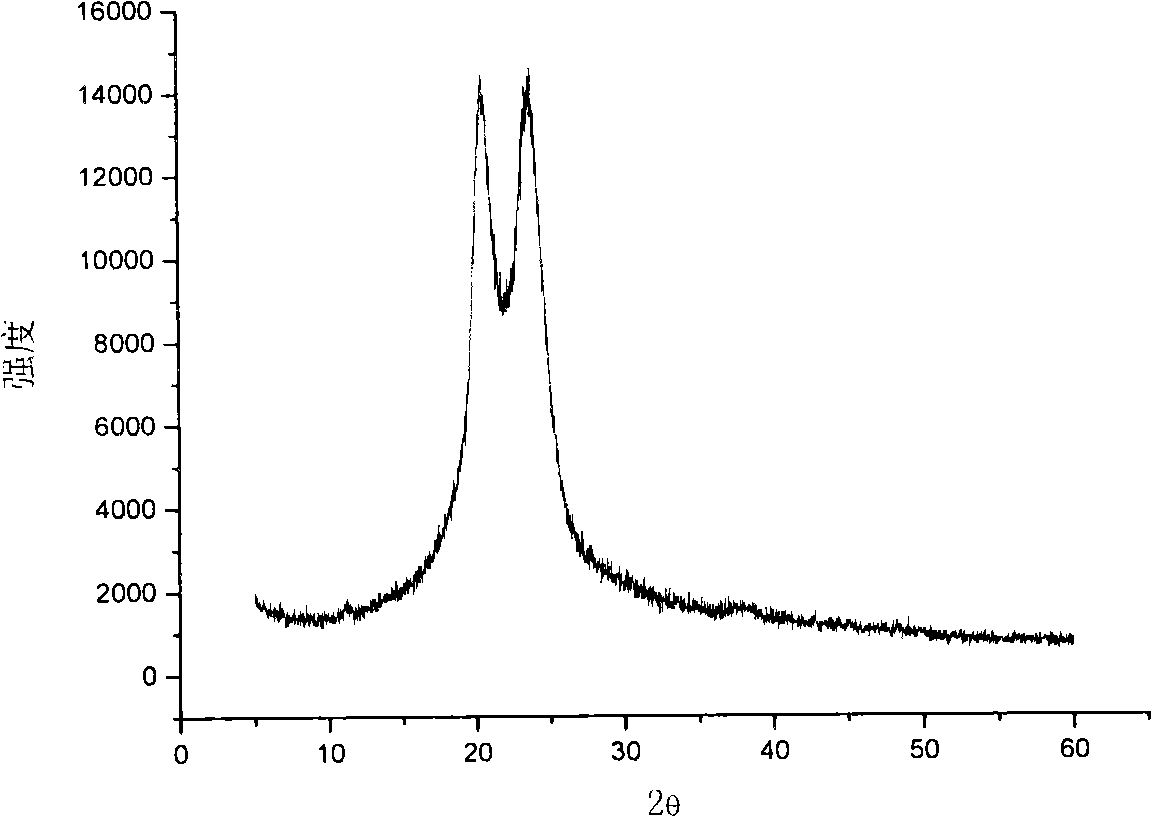

Method used

Image

Examples

Embodiment 1

[0043] The present embodiment adopts nylon 66 textile as the base material, and the activation steps are as follows:

[0044] 1. Configure chitosan finishing solution

[0045] Working fluid formula:

[0046]

[0047] The chitosan finishing solution was obtained after electromagnetic stirring for 30 minutes at room temperature and standing for another 3 hours.

[0048] 2. Treat the fabric with a chitosan finishing solution under electromagnetic stirring for 30 minutes, at a temperature of 60° C., wash with deionized water, and dry.

[0049] 3. The fabric with the chitosan carrier layer was placed in a 30 ppm palladium chloride activation solution, treated at 20° C. for 20 minutes, washed twice with deionized water, and dried.

[0050] After the nylon 66 textile is treated with electroless nickel-phosphorus alloy, an electromagnetic shielding material is obtained. The measured surface resistance value of the material is 0.1-0.2Ω / □, the shielding efficiency is 35dB, and the ...

Embodiment 2

[0052] This embodiment uses polyester primary color fabric as the base material, and the activation steps are as follows:

[0053] 1. Configure chitosan finishing solution

[0054] Working fluid formula:

[0055]

[0056] The chitosan finishing solution was obtained after electromagnetic stirring for 30 minutes at room temperature and standing for another 3 hours.

[0057] 2. Immerse the fabric in the chitosan finishing solution for 5 minutes at a pressure of 3kg / cm 2 Under the condition of two dips and two rollings, drying at 100°C for 5 minutes and at 145°C for 30 minutes.

[0058] 3. Put the fabric with the chitosan carrier layer in 20ppm palladium chloride activation solution, stir electromagnetically for 15 minutes at 20°C, and bake at 140°C for 30 minutes.

[0059] After the polyester primary color fabric is treated with electroless nickel-phosphorus alloy, an electromagnetic shielding material is obtained. The measured surface resistance value of the material is 0...

Embodiment 3

[0061] This embodiment uses polyester black fabric as the base material, and the activation steps are as follows:

[0062] 1. Configure chitosan finishing solution

[0063] Working fluid formula:

[0064]

[0065] The chitosan finishing solution was obtained after electromagnetic stirring for 30 minutes at room temperature and standing for another 3 hours.

[0066] 2. Immerse the fabric in the chitosan finishing solution for 10 minutes at a pressure of 2kg / cm 2 Under the condition of two dips and two rollings, drying at 100°C for 5 minutes and at 145°C for 30 minutes.

[0067] 3. Put the fabric with the chitosan carrier layer in 35ppm palladium chloride activation solution, stir electromagnetically for 35 minutes at 20°C, and bake at 120°C for 40 minutes.

[0068] After the polyester black fabric is treated with electroless nickel-phosphorus alloy, an electromagnetic shielding material is obtained. The measured surface resistance value of the material is 0.2-0.3Ω / □, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com