Inorganic nano SiO2 hybrid organic silicon fluoride-free waterproof agent and preparation method thereof

A fluorine-free water repellent and inorganic nano technology, which is applied in the field of textile dyeing auxiliaries, can solve the problems of limited use of fluorine-containing water repellants, poor fabric feel, complicated preparation methods, etc., and achieves obvious waterproof effect, improved washing resistance, Guaranteed long-lasting results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

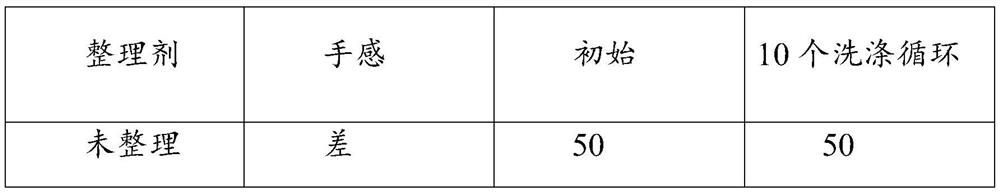

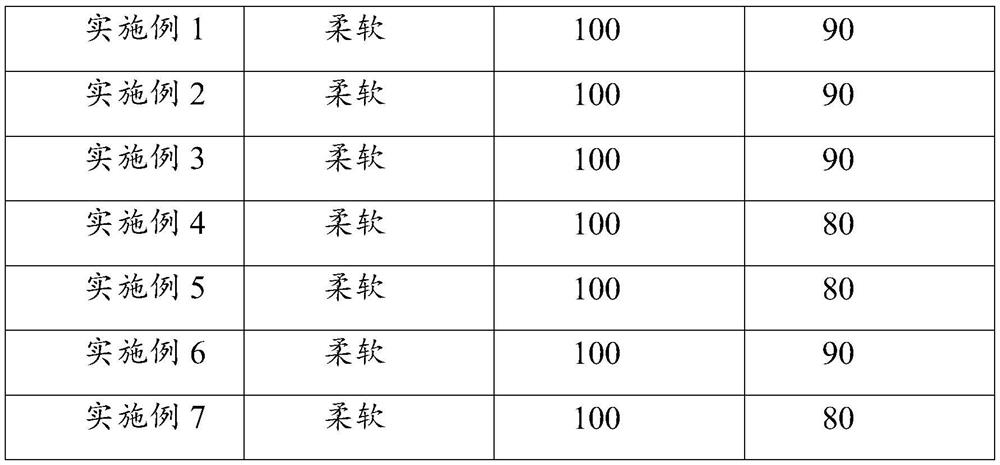

Examples

Embodiment 1

[0037] Add 81.4g octamethylcyclotetrasiloxane linear body, 0.12g tetramethylammonium hydroxide and 8.36g distilled water into the reaction vessel, stir, heat up to 85°C for 2 hours, cool down to 60°C, add 1.5gN-β- (Aminoethyl)-γ-aminopropylmethyldimethoxysilane, 8.4g hexadecyltrimethoxysilane and 0.22g tetramethylammonium hydroxide, heat up to 120°C, react for 2h, cool down and reduce pressure Low boilers are removed by distillation to obtain cross-linked long-chain alkyl / amino co-modified silicone;

[0038] In another reaction vessel, add 2.53g nanometer SiO in 27.60g toluene simultaneously 2 (average particle size is 80nm), ultrasonically disperse at room temperature for 30min to obtain a uniform suspension, then add 1.93g of coupling agent γ-(2,3-glycidyloxy)propyltrimethoxysilane, ultrasonically Disperse for 5 minutes, then magnetically stir and reflux for 6 hours under the reaction condition of 90°C, centrifuge at high speed, wash several times and then dry to obtain epo...

Embodiment 2

[0041] Add 85.4g octamethylcyclotetrasiloxane linear body, 0.12g tetramethylammonium hydroxide and 3.56g distilled water into the reaction vessel, stir, heat up to 90°C for 2.5h, cool down to 60°C, add 1.4gN-β -(Aminoethyl)-γ-aminopropylmethyldimethoxysilane, 9.3g hexadecyltrimethoxysilane and 0.22g tetramethylammonium hydroxide, heated up to 130°C, reacted for 1h, cooled down Pressure distillation to remove low boilers to obtain cross-linked long-chain alkyl / amino co-modified organosilicon;

[0042] In another reaction vessel, add 2.18g nanometer SiO in 28.4g toluene simultaneously 2 (average particle size is 80nm), ultrasonically disperse at room temperature for 30min to obtain a uniform suspension, then add 1.91g coupling agent γ-(2,3-glycidyloxy)propyltrimethoxysilane to it, ultrasonically Disperse for 5 minutes, then magnetically stir and reflux for 6 hours under the reaction condition of 90°C, centrifuge at high speed, wash several times and then dry to obtain epoxy-mod...

Embodiment 3

[0046] Add 86.2g octamethylcyclotetrasiloxane linear body, 0.12g tetramethylammonium hydroxide and 3.26g distilled water into the reaction vessel, stir, raise the temperature to 95°C for 2 hours, cool down to 60°C, add 0.8g N-β- (Aminoethyl)-γ-aminopropylmethyldimethoxysilane, 9.4g hexadecyltrimethoxysilane and 0.22g tetramethylammonium hydroxide, heat up to 120°C, react for 2h, cool down and reduce pressure Low boilers are removed by distillation to obtain cross-linked long-chain alkyl / amino co-modified silicone;

[0047] In another reaction vessel, add 2.42g nanometer SiO in 28.4g toluene simultaneously 2 (average particle size is 80nm), ultrasonically disperse at room temperature for 30min to obtain a uniform suspension, then add 1.32g coupling agent γ-(2,3-glycidyloxy)propyltrimethoxysilane to it, ultrasonically Disperse for 5 minutes, then magnetically stir and reflux for 6 hours under the reaction condition of 90°C, centrifuge at high speed, wash several times and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com