Process for producing cigarette label by replacing large-area hot stamping with local dealuminization transfer

A production process and large-area technology, applied in the printing process, printing of special varieties of printed matter, post-processing of printing, etc., can solve the problem of high cost of process application, achieve wide application range, excellent quality, and reduce equipment investment level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

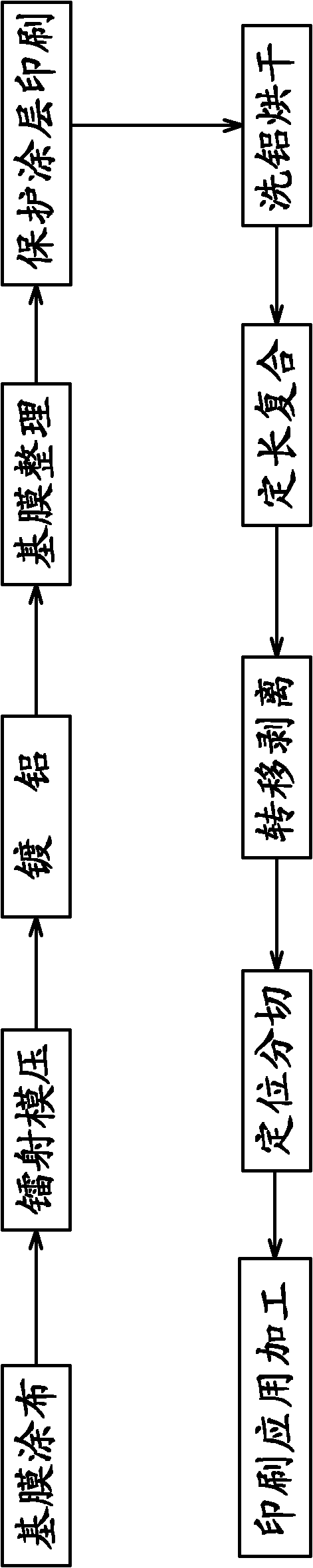

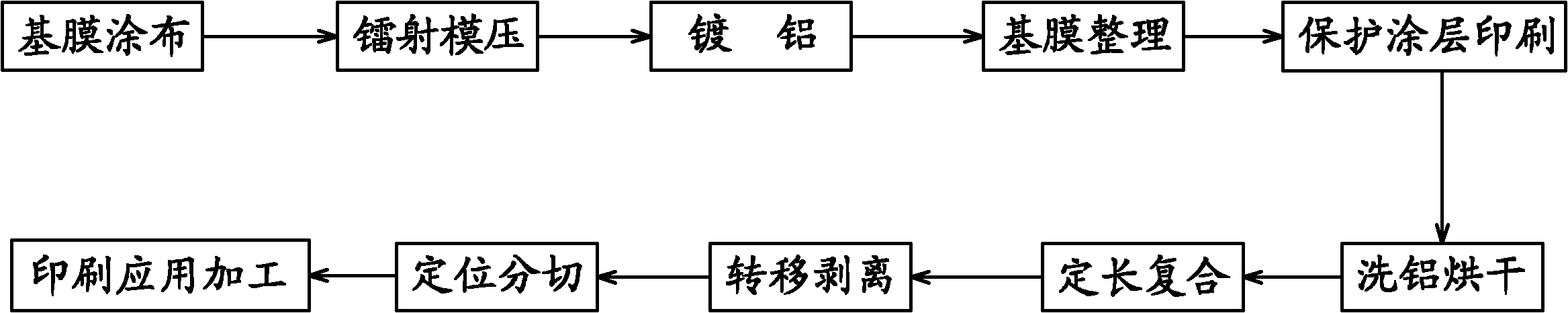

Image

Examples

Embodiment Construction

[0025] The present invention is a cigarette label production process that replaces large-area bronzing with partial aluminum washing and transfer, and the steps are as follows:

[0026] 1. Base film coating: use 23μ thick PET base film as the substrate, use laser transfer coating to evenly coat the surface of the base film in the form of gravure printing, and dry it with infrared hot air to form a laser molded base layer for later use;

[0027] 2. Laser molding: Based on the coated PET base film, a molding working plate is installed on the molding machine, and the laser pattern on the molding working plate is transferred to the surface of the laser coating by hot molding, so that the surface of the base film is formed. Regular grooves required for laser effects, forming the base shape for directional reflections.

[0028] 3. Aluminum plating: aluminum plating by vacuum aluminum plating: in the aluminum plating machine, the coating of the base film forms an electrode, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com