Ink-jet printing coating adhesive for fabrics and preparation method

An inkjet printing and textile technology, applied in the field of coating glue, can solve the problems of unpublished materials, etc., and achieve the effects of good washing fastness, simple production method and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

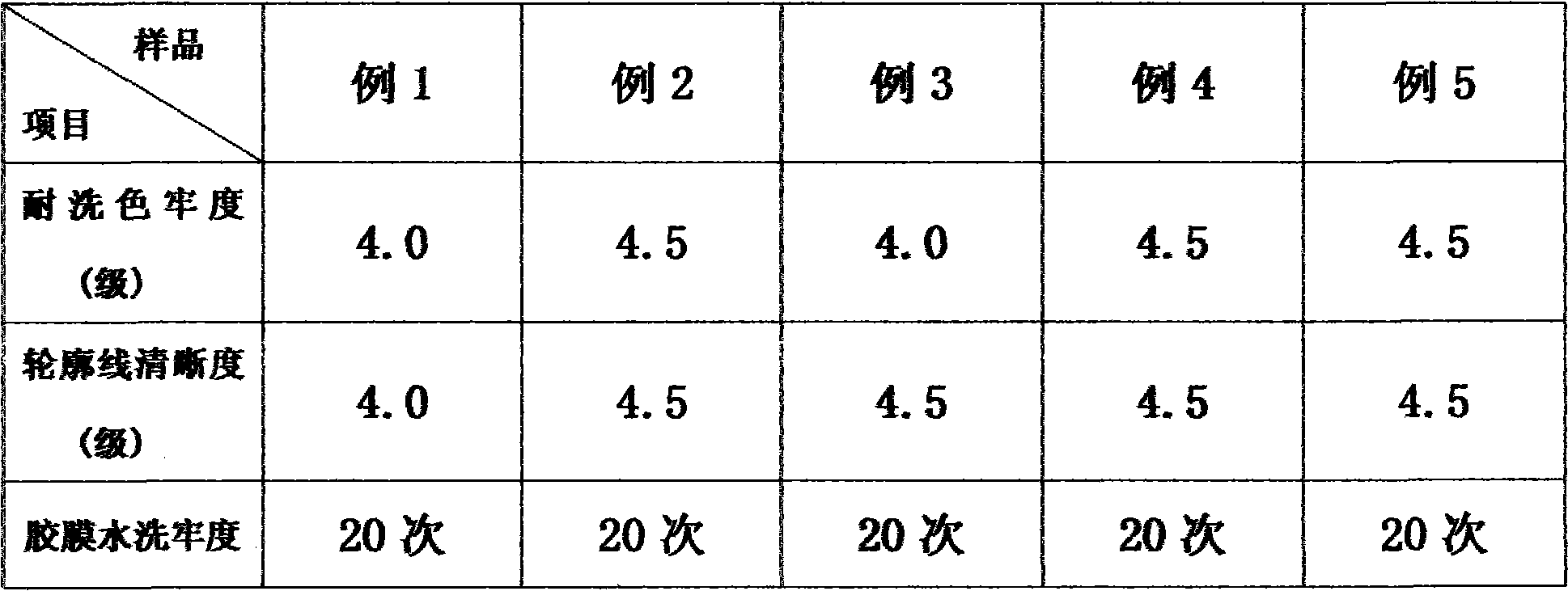

Examples

Embodiment 1

[0021] (1) Emulsified mixed monomer: add 25 grams of methyl methacrylate, 80 grams of n-butyl methacrylate, 3.0 grams of glycidyl methacrylate, 1.0 grams of allyl methacrylate, chlorinated 7.0 grams of trimethylaminoethyl methacrylate, 6.5 grams of fatty alcohol polyoxyethylene ether XL90, and 200 grams of deionized water were stirred and emulsified for 30 minutes to prepare an emulsion.

[0022] (2) Initiate polymerization reaction: Take 20% of the total amount of the emulsion and add it to the reactor, heat up to 72-75°C, add initiator 2, 0.2 grams of 2-azobis(2-methylpropionamidine) hydrochloride Mixed solution with 10 grams of water to initiate, then drop the remaining emulsion at 72-75 ° C, and simultaneously add initiator 2, 0.8 grams of 2-azobis (2-methylpropionamidine) hydrochloride and The mixed solution of 30 grams of water was added dropwise in 2.5 hours, kept at 82-85°C for 1.5 hours, then cooled to 40-45°C, stirred evenly, and filtered to obtain the emulsion;

[...

Embodiment 2

[0026] The weight ratio of raw materials is: 26 grams of methyl methacrylate, 82 grams of n-butyl methacrylate, 5.0 grams of glycidyl methacrylate, 1.2 grams of allyl methacrylate, trimethylaminoethyl methacrylate 7.5 grams of ester, 6.8 grams of fatty alcohol polyoxyethylene ether XL90, 7.5 grams of cetyltrimethylammonium chloride, 1.2 grams of 2,2-azobis (2-methylpropionamidine) hydrochloride, 205 grams of ionized water, nano-SiO 2 34 grams, associative polyurethane leveling rheology agent WT-203 is 3.7 grams, and the production process is the same as in Example 1.

Embodiment 3

[0028] The weight ratio of raw materials is: 27 grams of methyl methacrylate, 85 grams of n-butyl methacrylate, 4.5 grams of glycidyl methacrylate, 1.4 grams of allyl methacrylate, trimethylaminoethyl methacrylate 8.0 grams of ester, 7.1 grams of fatty alcohol polyoxyethylene ether XL90, 8.0 grams of cetyltrimethylammonium chloride, 1.5 grams of 2,2-azobis (2-methylpropionamidine) hydrochloride, 210 grams of ionized water, nano-SiO 2 35 grams, associative polyurethane leveling rheology agent WT-203 is 3.9 grams, and the production process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com