Moso bamboo extrusion-flattening processing device and method

A technology of processing device and flattening device, which is applied in the direction of wood processing equipment, sugarcane machining, manufacturing tools, etc. and other issues, to achieve broad development prospects, enhance the technological content and the effect of product added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

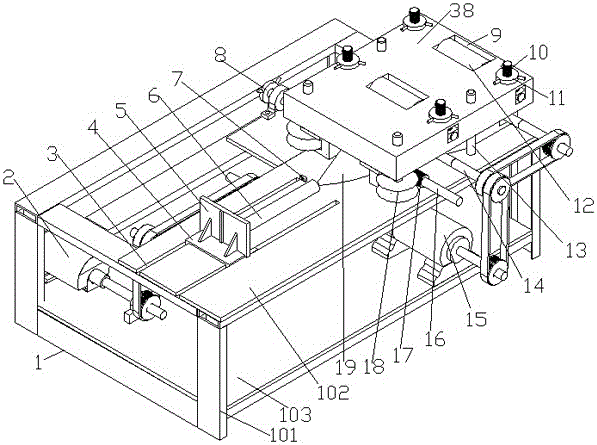

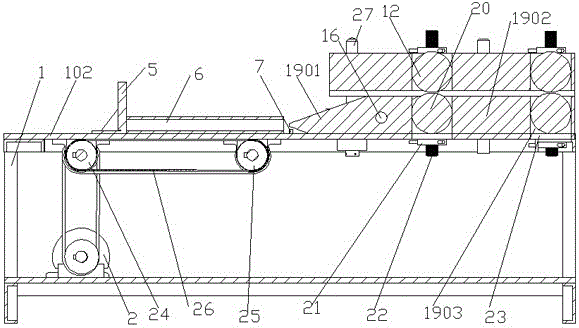

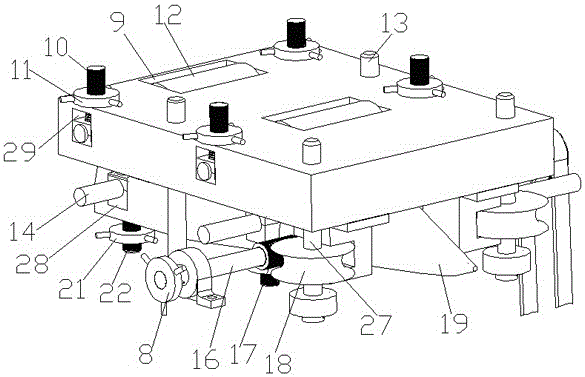

[0032] Such as Figure 1-6 Shown, a kind of bamboo extrusion flattening processing device and extrusion flattening processing method comprise frame 1, feeding device, extrusion flattening device, described frame 1 comprises frame body 101, is arranged on frame body 101 The machine platform 102 on the upper side, the platform 103 arranged on the lower part of the frame body 101, and the frame 1 are welded and processed by No. 10 channel steel to ensure that the whole equipment has sufficient weight and stability, and the processing accuracy of the device is guaranteed. The extruding flattening device comprises a flattening tongue plate 19 arranged on the machine platform 102, a drive motor 15 arranged on a platform 103, an elevating platform 38 positioned above the flattening tongue plate 19, and the front end of the flattening tongue plate 19 is a cone part 1901, the upper and lower end faces of the cone part 1901 are flat, and the rear end of the flattened tongue plate 19 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com