Flattening method for bamboo tubs in high-temperature tank

A high-temperature tank and bamboo tube technology, which is applied in reed/straw treatment, wood treatment, wood processing appliances, etc., can solve the problem of high compressive strength of pressure tanks, and achieve the effects of reduced strength, short maturity period and easy reproduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The bamboo tube flattening method in the high temperature tank includes the following steps:

[0017] (1) The diameter is 80mm, and the fresh bamboo tube is cut for 10 days and cut to 1200mm length as required. The inner and outer sections of the rotating bamboo tube are removed at the same time through an inner milling cutter and an outer planing knife, and then the bamboo tube is opened One longitudinal straight saw slit;

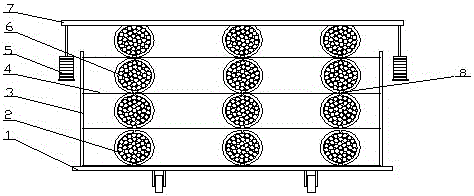

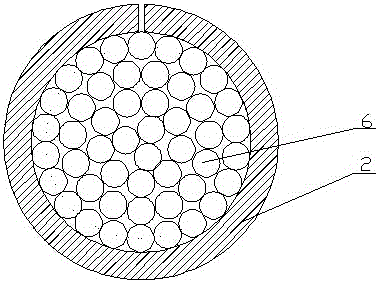

[0018] (2) Stacking of bamboo tubes: Place the treated bamboo tube 2 on a backing plate 4 with a thickness of 4mm, and fix 4 bamboo tubes on the backing plate. The saw slits of the bamboo tube 2 are facing upwards. The device 8 fixes it with the backing plate. Each round bamboo tube is filled with a round steel 6 with a diameter of 15mm. The length of the round steel is the length of the bamboo tube plus 30mm. The length of the multi-layer backing board has semi-circular positioning grooves on both sides , In order to align up and down in the tank, pre...

Embodiment 2

[0027] The bamboo tube flattening method in the high temperature tank includes the following steps:

[0028] (1) The diameter is 85mm, and the fresh bamboo tube is cut for 8 days and cut into 1000mm length as required. The inner and outer sections of the rotating bamboo tube are removed at the same time through an inner milling cutter and an outer planing knife, and then the bamboo tube is opened One longitudinal straight saw seam.

[0029] (2) Stacking of bamboo tubes: The treated bamboo tube 2 is placed on a mat 4 with a thickness of 3.5mm, and 3 bamboo tubes are fixed on the mat. The saw seam of the bamboo tube 2 faces upward, and the two ends of the bamboo tube pass through a clamp. The tightening device 8 fixes it with the backing plate. Each round bamboo tube is filled with a round steel 6 with a diameter of 12mm. The length of the round steel is the length of the bamboo tube plus 25mm. The length of the multi-layer backing board has a semi-circular positioning on both sides ...

Embodiment 3

[0038] The bamboo tube flattening method in the high temperature tank includes the following steps:

[0039] (1) The diameter is 90mm, and the fresh bamboo tube is cut for 6 days and cut into 1300mm length as required. The inner and outer sections of the rotating bamboo tube are removed at the same time through an inner milling cutter and an outer planing knife. Then cut a longitudinal straight saw slit on the bamboo tube.

[0040] (2) Stacking of bamboo tubes: Place the treated bamboo tube 2 on a backing plate 4 with a thickness of 4mm, and 5 bamboo tubes are fixed on the backing plate. The saw slits of the bamboo tube 2 are facing upwards. The device 8 fixes it with the backing plate. Each round bamboo tube is filled with a round steel 6 with a diameter of 13mm. The length of the round steel is the length of the bamboo tube plus 30mm. The length of the multi-layer backing board has semi-circular positioning grooves on both sides , In order to align up and down in the tank, press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com