Method for enhancing bonding performance of crop straw through water vapor dielectric barrier discharge plasma

A technology of dielectric barrier discharge and crop straw, which is applied in household components, electric wood treatment, pretreatment of molding materials, etc., can solve the problems of straw glueing difficulty, high production cost, complicated production process, etc., and achieve simple and controllable operation, Enhanced bonding performance and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

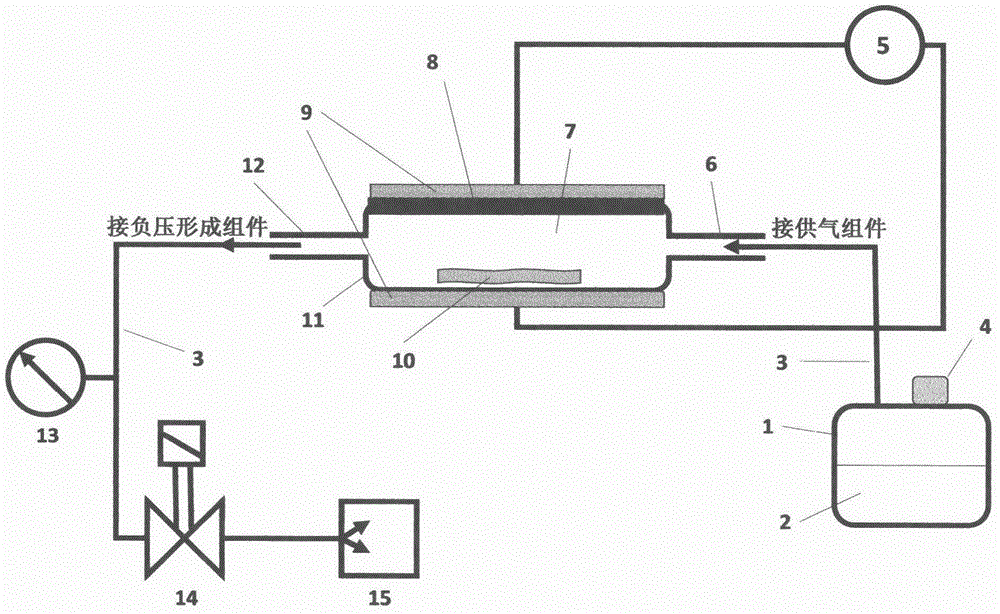

Method used

Image

Examples

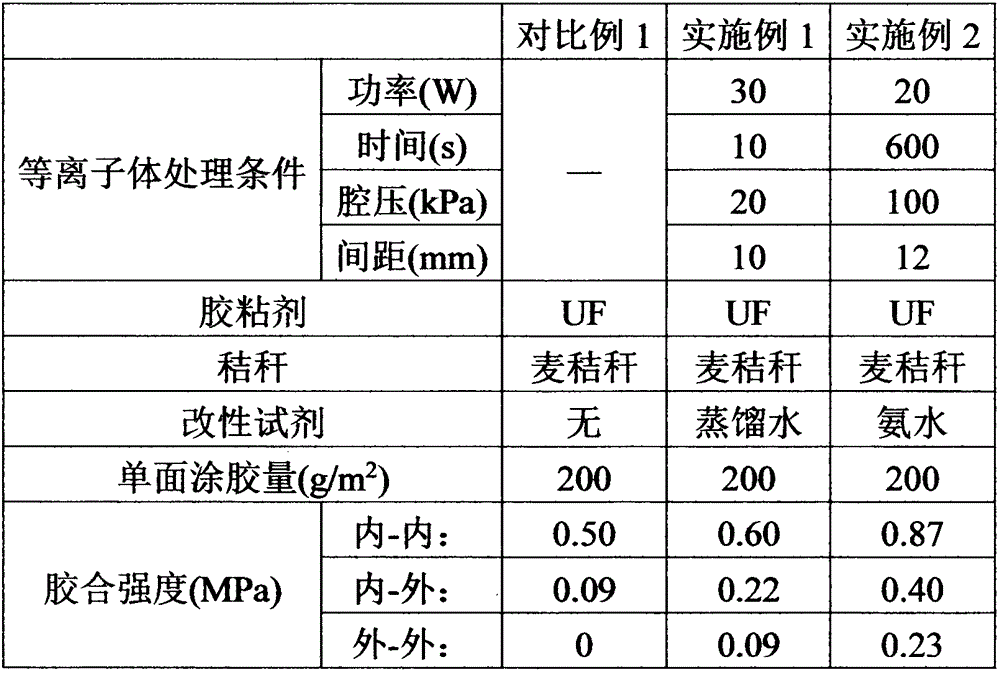

Embodiment 1

[0026] After removing the leaves, sheaths and joints of the current year's wheat straw, select the smooth and flat part and cut it into 5cm long, cut it from the middle with a knife, soak it in distilled water for 5 hours, and after it is fully softened, spread it evenly on the glass and place it in a ventilated place. Press it with a heavy object for a week, then take it off, place it in a screen, and dry it in a blast drying oven at 60 degrees Celsius for 1 hour until the moisture content reaches about 8%, then seal the bag and store it in a drying dish for later use.

[0027] Cut the wheat straw flattened and dried in the early stage into 10 cm long, and measure 2 cm at the flat end of the straw as the glued and glued part, measure the width, and calculate the glued area.

[0028] Open the quartz cover plate 8, place the trimmed straw in the quartz reaction chamber between the two electrode plates of the dielectric barrier discharge plasma discharge device, and cover the cover...

Embodiment 2

[0030] After removing the leaves, sheaths and joints of the current year's wheat straw, select the smooth and flat part and cut it into 5cm long, cut it from the middle with a knife, soak it in distilled water for 5 hours, and after it is fully softened, spread it evenly on the glass and place it in a ventilated place. Press it with a heavy object for a week, then take it off, place it in a screen, and dry it in a blast drying oven at 60 degrees Celsius for 1 hour until the moisture content reaches about 8%, then seal the bag and store it in a drying dish for later use.

[0031] Cut the wheat straw flattened and dried in the early stage into 10 cm long, and measure 2 cm at the flat end of the straw as the glued and glued part, measure the width, and calculate the glued area. It is placed between two insulating media of a dielectric barrier discharge plasma discharge device for modification treatment. Using the steps described in Example 1, ammonia water was used as the modifyi...

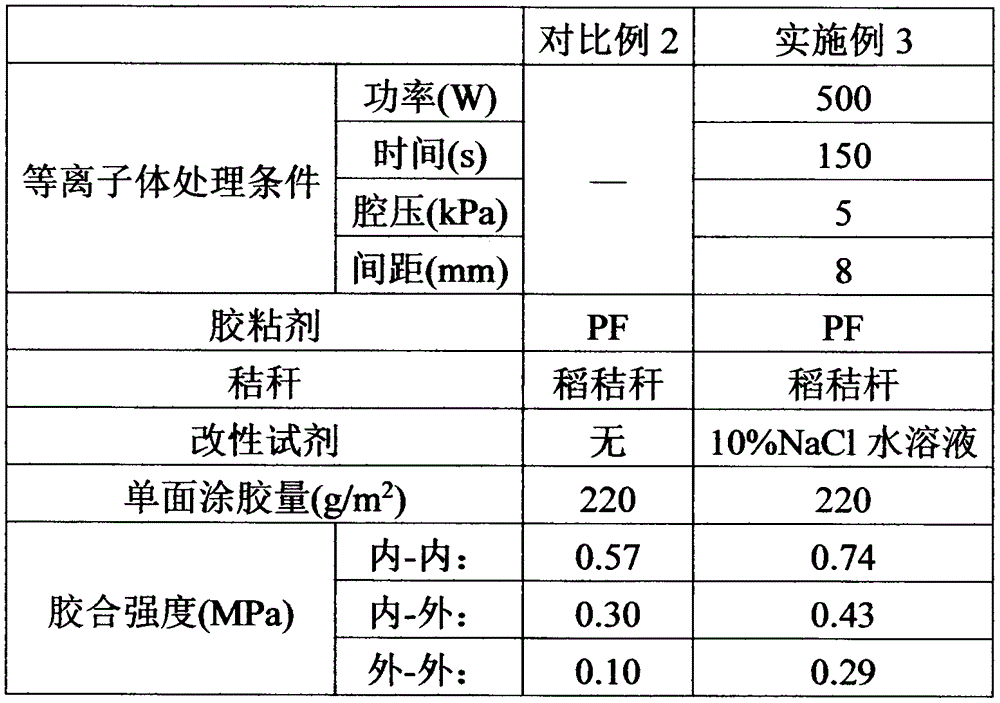

Embodiment 3

[0033] After removing leaves, sheaths and joints, select the smooth and flat part and cut it into 5cm long, cut it open from the middle with a knife, soak it in distilled water for 3 hours, fully soften it, spread it evenly on the glass, and place it in a ventilated place. Press it with a heavy object for a week, then take it off, place it in a screen, and dry it in a blast drying oven at 60 degrees Celsius for 2 hours until the moisture content reaches about 6%, and then store it in a sealed bag in a drying dish for later use.

[0034] Cut the wheat straw flattened and dried in the early stage into 10 cm long, and measure 2 cm at the flat end of the straw as the glued and glued part, measure the width, and calculate the glued area. It is placed between two insulating media of a dielectric barrier discharge plasma discharge device for modification treatment. Using the steps described in Example 1, 10% NaCl aqueous solution was used as the modifying reagent. By heating 10% NaC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com