Liquid Phase Uniform Mixing Treatment Discharge Device

A uniform mixing and discharge device technology, which is applied in discharge tubes, water/sewage treatment, water/sewage treatment equipment, etc., can solve the problems of uneven sterilization effect, high discharge requirements, and low efficiency, and achieve good sterilization and disinfection effects. The effect of low discharge voltage requirement and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

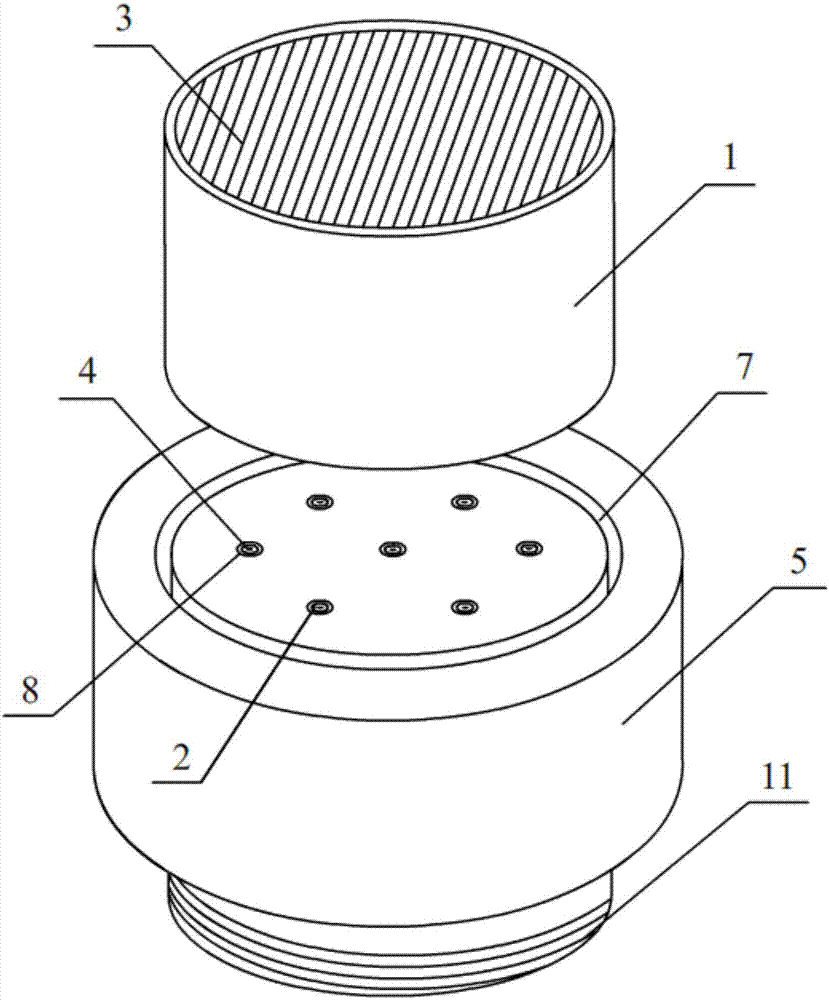

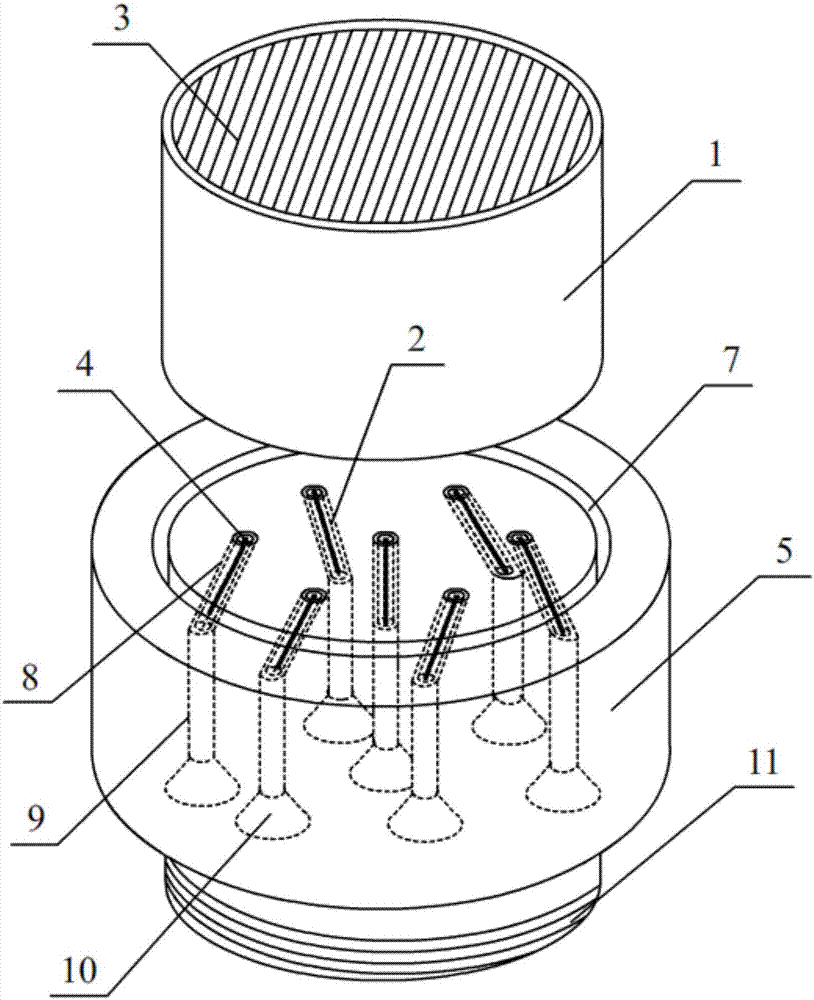

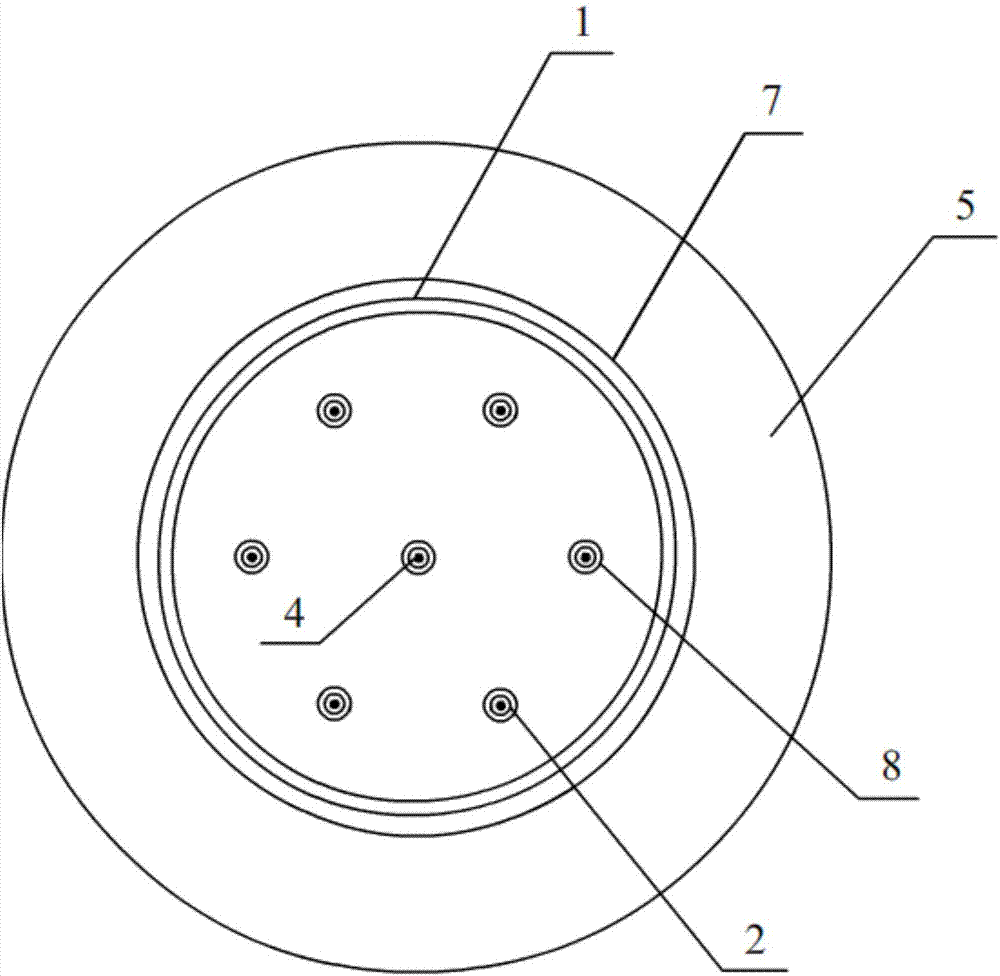

[0028] Such as Figure 1-9 As shown, the present invention mainly includes a quartz tube A1, a quartz tube B2, a ground electrode 3, a high voltage electrode 4, a dielectric body A5 and a dielectric body B6. , insert and fix the quartz tube A in the card slot, plate a layer of metal film on the inner wall of the quartz tube A as the ground electrode, and process a plurality of pipes 8 of equal size obliquely downward from the top surface of the medium body A, and the upper ends of all the pipes are open They are all arranged on the surface of the medium body A in the ring-shaped groove ring, and the inclination angles of all the pipes are the same and arranged in an equiangular order in the axial direction. The opening at the bottom of each pipeline communicates with the vertically downward ventilation pipeline 9, and the bottom opening of the ventilation pipeline adopts a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com