Manufacturing method of low-glue environmental protecting plywood

A manufacturing method and technology of plywood, applied in the direction of manufacturing tools, joining of wooden veneers, chemical instruments and methods, etc., can solve problems such as difficulties in importing high-quality large-diameter logs, rising prices of plywood raw materials, and expensive chemical raw materials, etc. Achieve low production cost, increase product value, and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

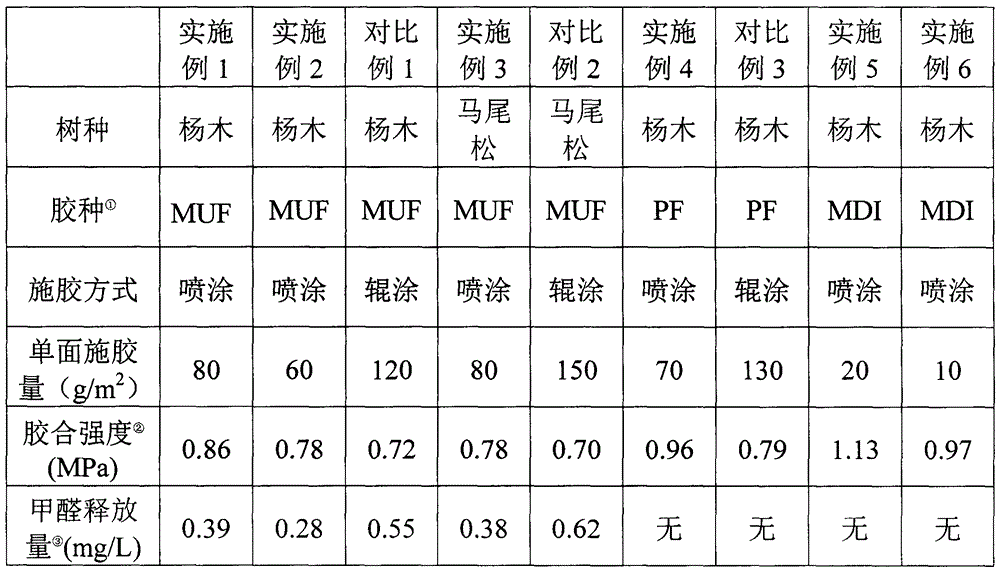

Examples

Embodiment 1

[0023] The small-diameter fast-growing poplar is cut into a certain length of wood with a circular saw. The length of the wood is determined according to the requirements of the plywood product format, usually the length of the plywood product is ±100-150mm. Put the wood section in the cooking tank for softening treatment to increase the plasticity of the wood to improve the quality of the rotary cut veneer. In order to ensure the quality of plywood, a special stripping machine is required to remove the bark of the wood section. Then, use a mechanical centering machine to determine the center of rotation of the wood section, and then use a wooden machine to place the wood section on a rotary cutting machine, and then rotary cut it into a veneer with a thickness of 1mm.

[0024] Put the poplar veneer in a hot plate dryer to dry under a certain pressure (less than 0.1MPa). The drying temperature should not be too high and should be controlled below 80°C to prevent warping and de...

Embodiment 2

[0028] The small-diameter fast-growing poplar is made into a veneer with a thickness of 2mm and a moisture content of 6% by the same steps as in Example 1.

[0029] Put the dried veneer on the feeding conveyor belt of the integrated device of low-temperature plasma modification and micro-sizing of wood veneer, enter the low-temperature plasma treatment area driven by the feeding roller, and adjust the upper and lower four pairs of discharge The distance between the electrodes was 10 mm. Turn on the low-temperature plasma power supply and adjust the processing power to 4.5KW. When the voltage between the electrodes reaches the air discharge voltage, a dielectric barrier discharge is formed between the electrodes to generate low-temperature plasma. Poplar veneers are suspended in the air at a speed of 10m / min. The four pairs of electrodes pass continuously through the gap, and the low-temperature plasma modification treatment is performed on the upper and lower surfaces of the v...

Embodiment 3

[0035] Masson pine logs were made into veneers with a thickness of 2mm and a moisture content of 6% by the same steps as in Example 1.

[0036] Put the dried veneer on the feeding conveyor belt of the integrated device of low-temperature plasma modification and micro-sizing of wood veneer, enter the low-temperature plasma treatment area driven by the feeding roller, and adjust the upper and lower four pairs of discharge The distance between the electrodes was 10 mm. Turn on the low-temperature plasma power supply and adjust the processing power to 4.5KW. When the voltage between the electrodes reaches the air discharge voltage, a dielectric barrier discharge is formed between the electrodes to generate low-temperature plasma. Masson pine veneers are suspended in the air at a speed of 10m / min. The four pairs of electrodes pass continuously through the gap, and the low-temperature plasma modification treatment is performed on the upper and lower surfaces of the veneer at the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com