Patents

Literature

36results about How to "Reduce processing power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

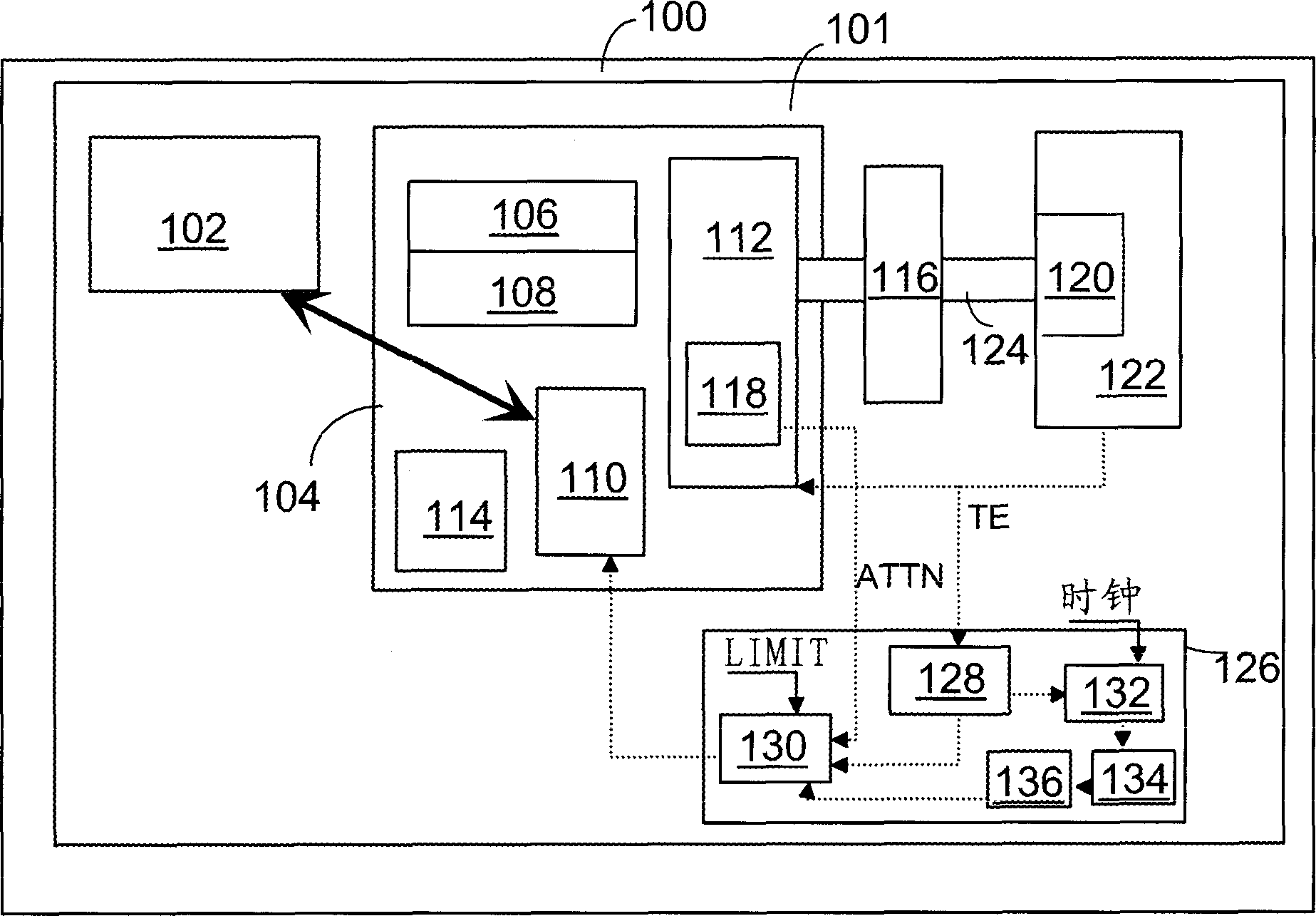

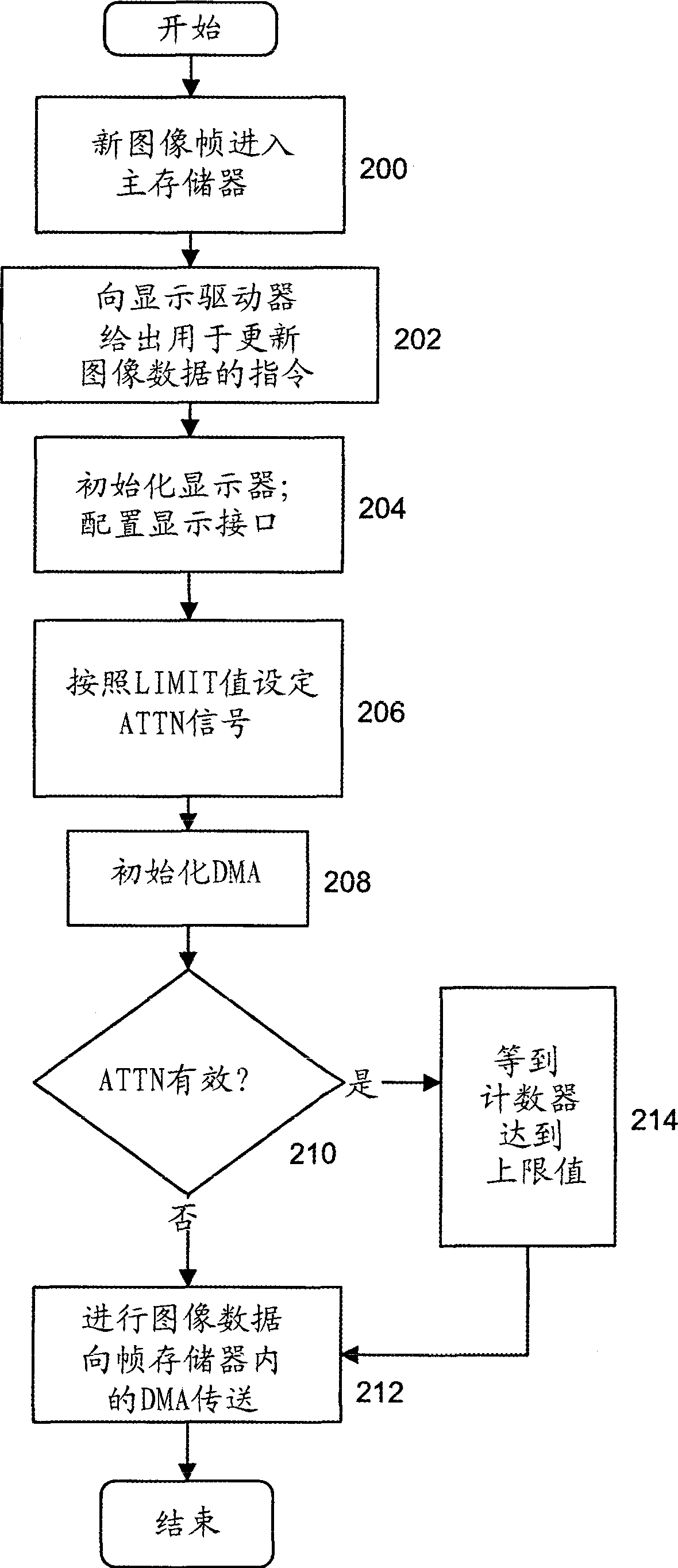

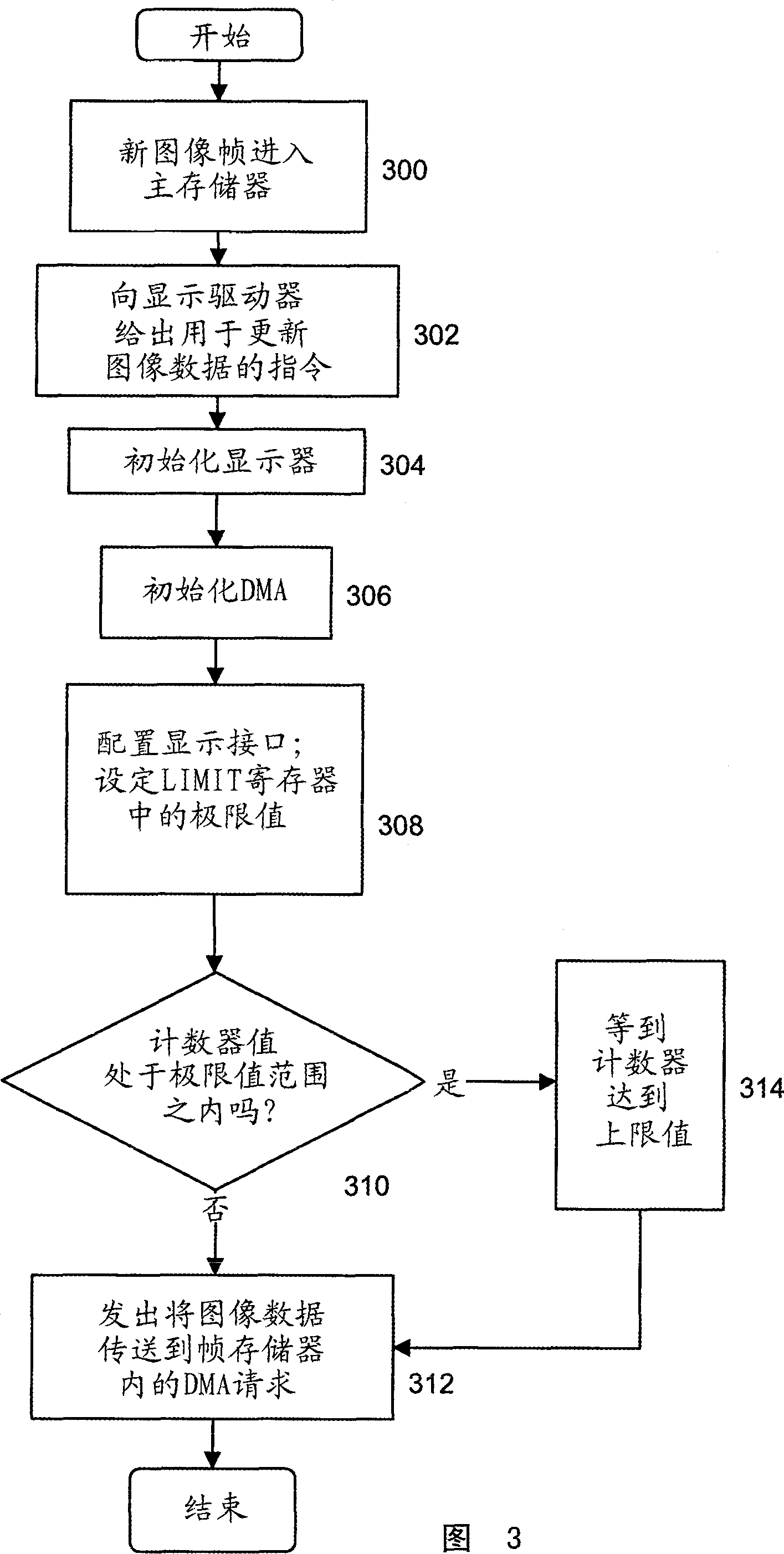

Synchronization of image frame update

InactiveCN1816844AMake sure to update regularlyDoes not cause synchronization issues with updatesCathode-ray tube indicatorsDigital output to display deviceComputer graphics (images)Limit value

A method of updating image frames to a display screen. A display system comprises a display screen, a frame memory for buffering the image frames prior to a transfer to the display screen, a display interface for receiving the image data into the frame memory, a separate controller for inputting the image data in the frame memory, and a display driver for controlling the display system. Image data are transferred by means of the separate controller to the display screen, after which a synchronization signal is fed back from the image frame updated to the display screen. A limiter register is used to specify a moment when image frame update in the frame memory is prevented. The separate controller is controlled to prevent image frame input in the frame memory as long as the counter value is within the limits of the limit value of the limiter register.

Owner:NOKIA CORP

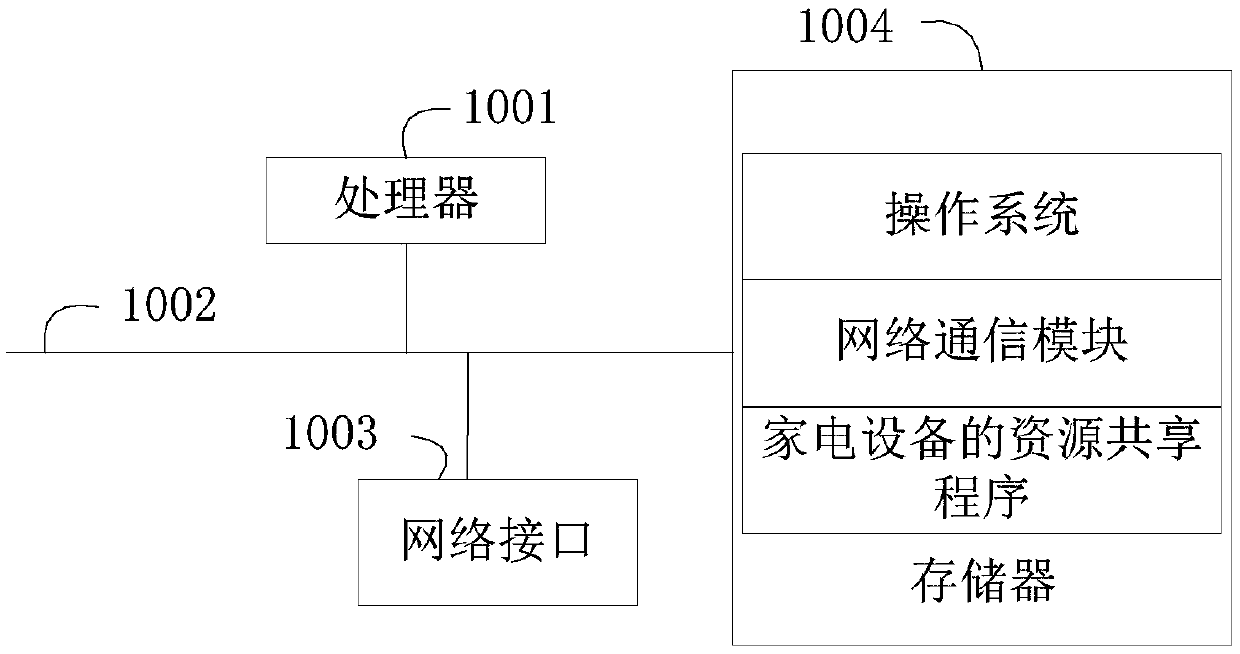

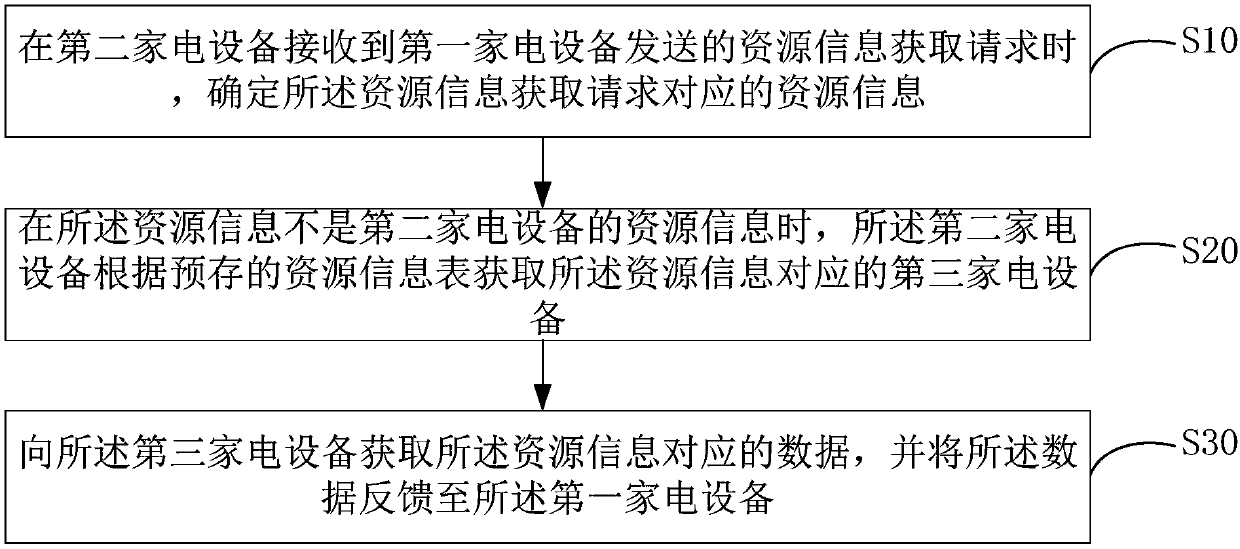

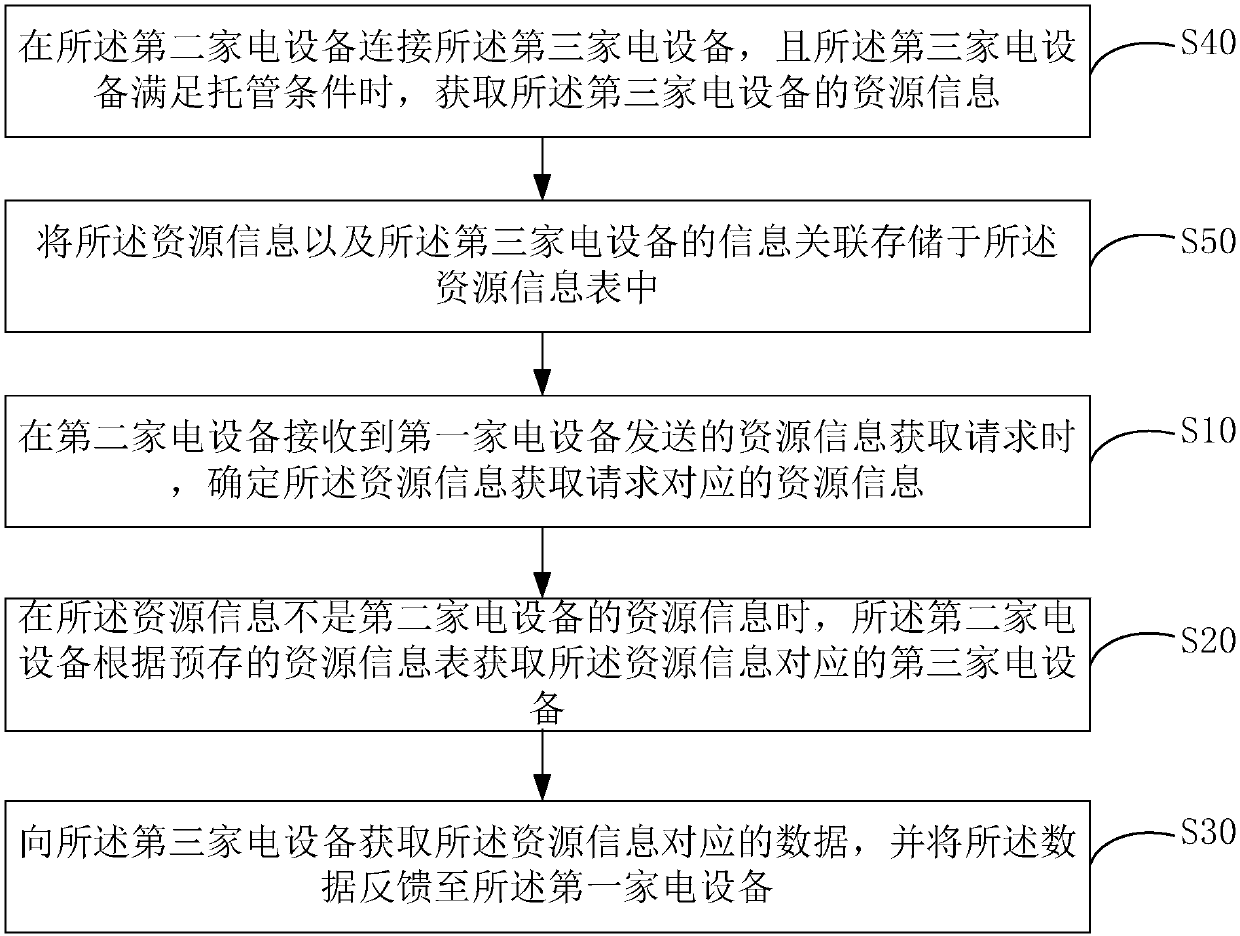

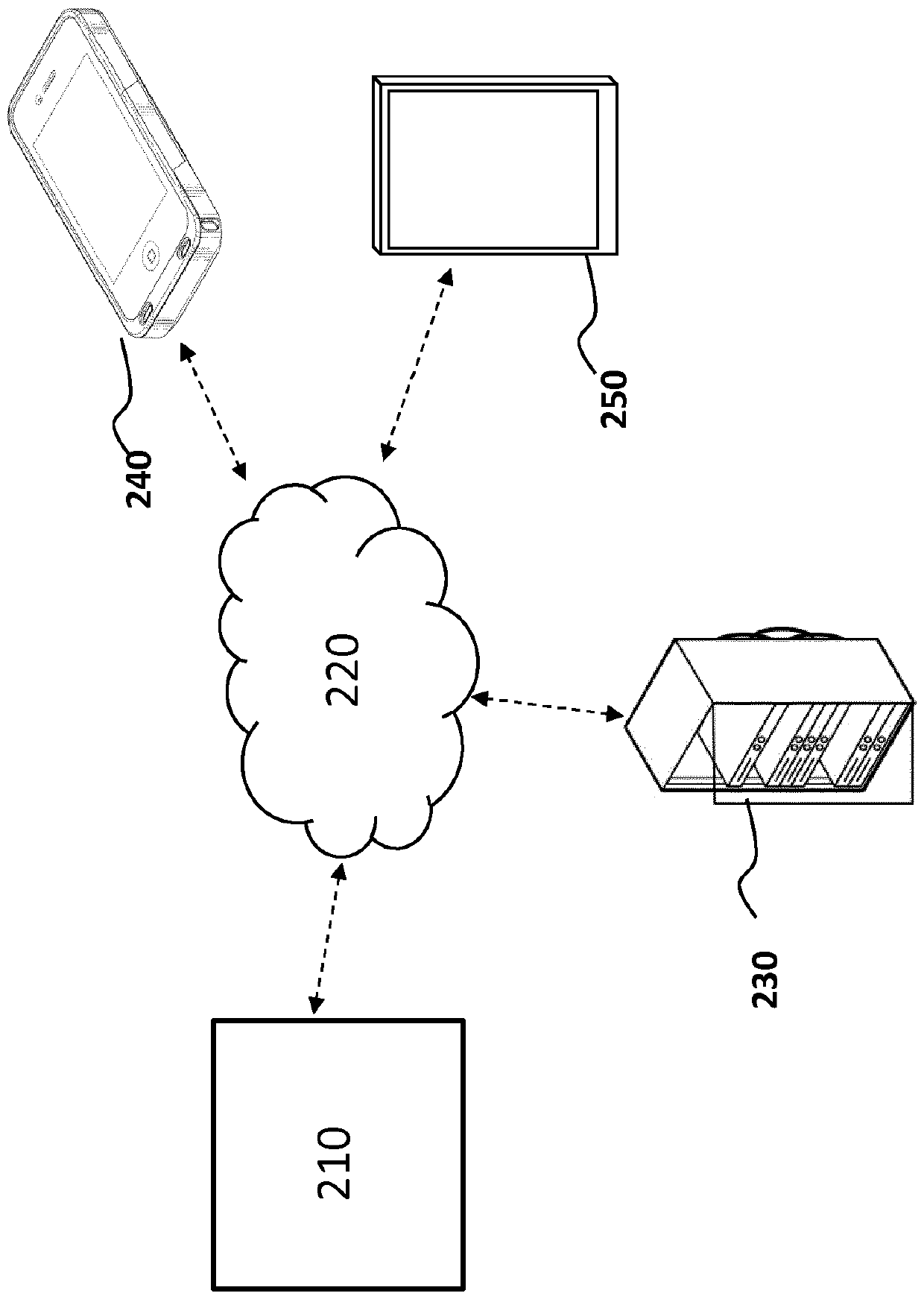

Resource sharing method and device for household appliances and computer readable storage medium

ActiveCN107592367AReduce processing powerLow costData switching by path configurationInternet of ThingsDistributed computing

The invention discloses a resource sharing method for household appliances. The method comprises the following steps: when a second household appliance receives a resource information acquisition request sent by a first household appliance, determining resource information corresponding to the resource information acquisition request; when the resource information is not resource information of the second household appliance, acquiring a third household appliance corresponding to the resource information according to a pre-stored resource information table; acquiring data corresponding to theresource information from a third household appliance, and feeding back the data to the first household appliance. The invention also discloses a resource sharing detection device for household appliances and a storage medium. Through adoption of the resource sharing method and device, forwarding of the information or demand of the first household appliance by the second household appliance is realized, that is, the third household appliance is represented by the second household appliance; the requirement on the processing ability of the third household appliance is lower; and the cost of Internet of things communication is lowered.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

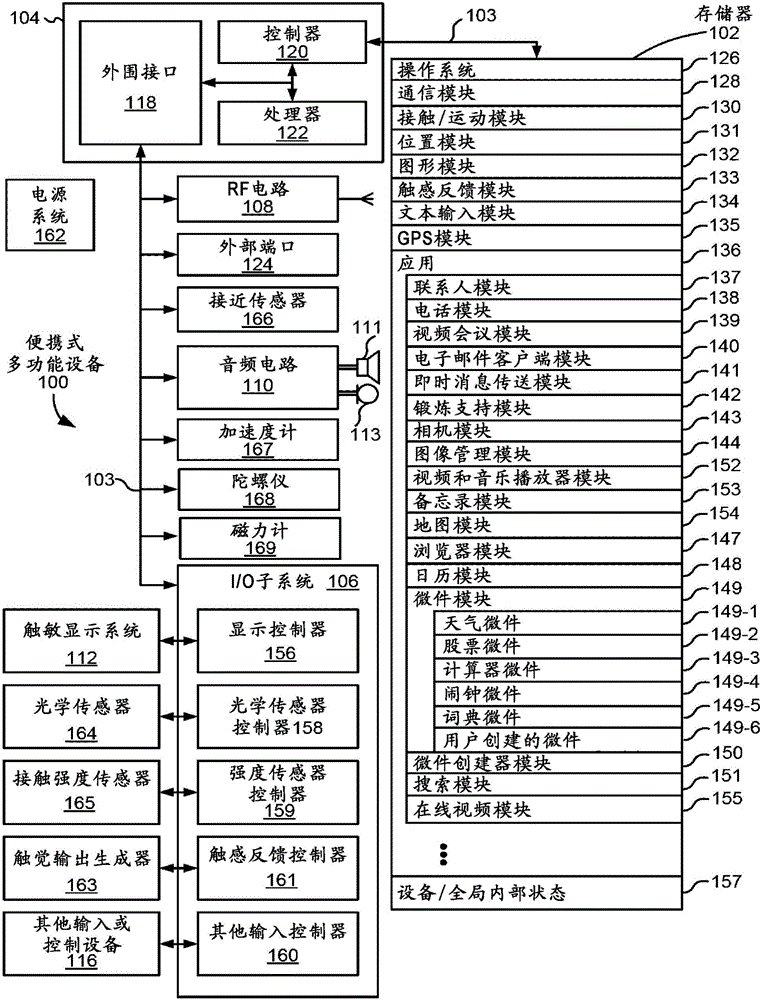

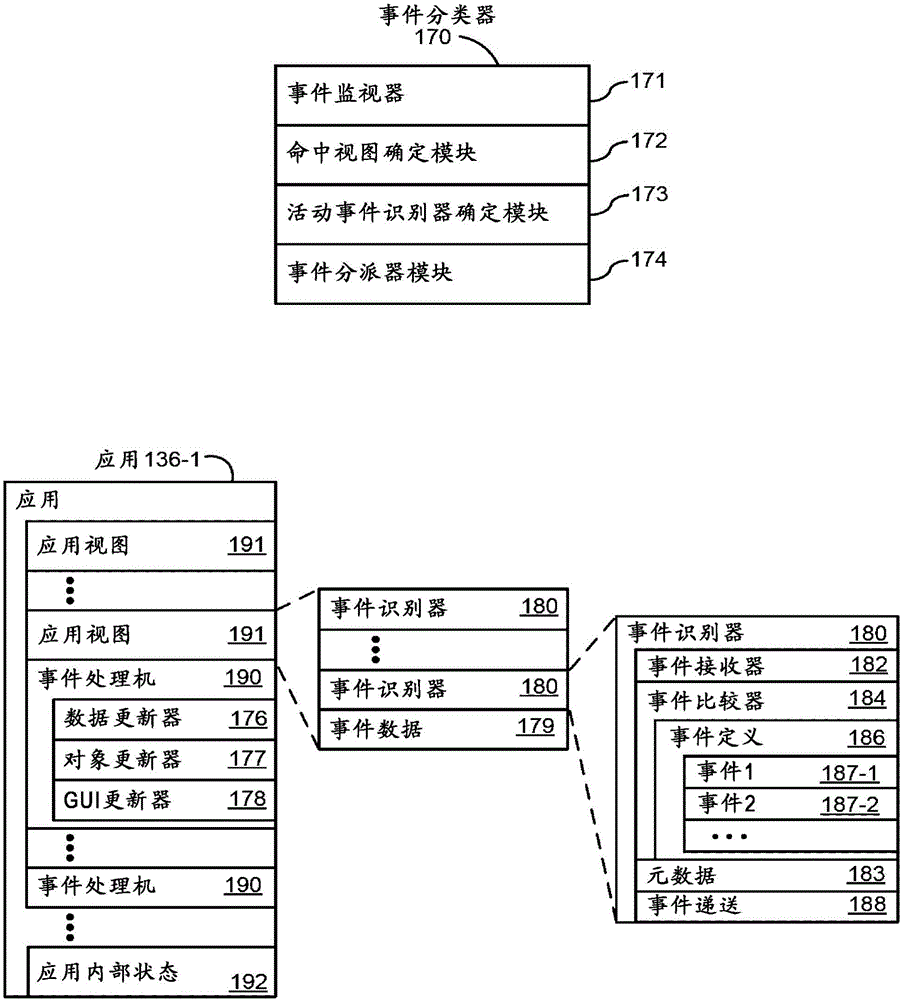

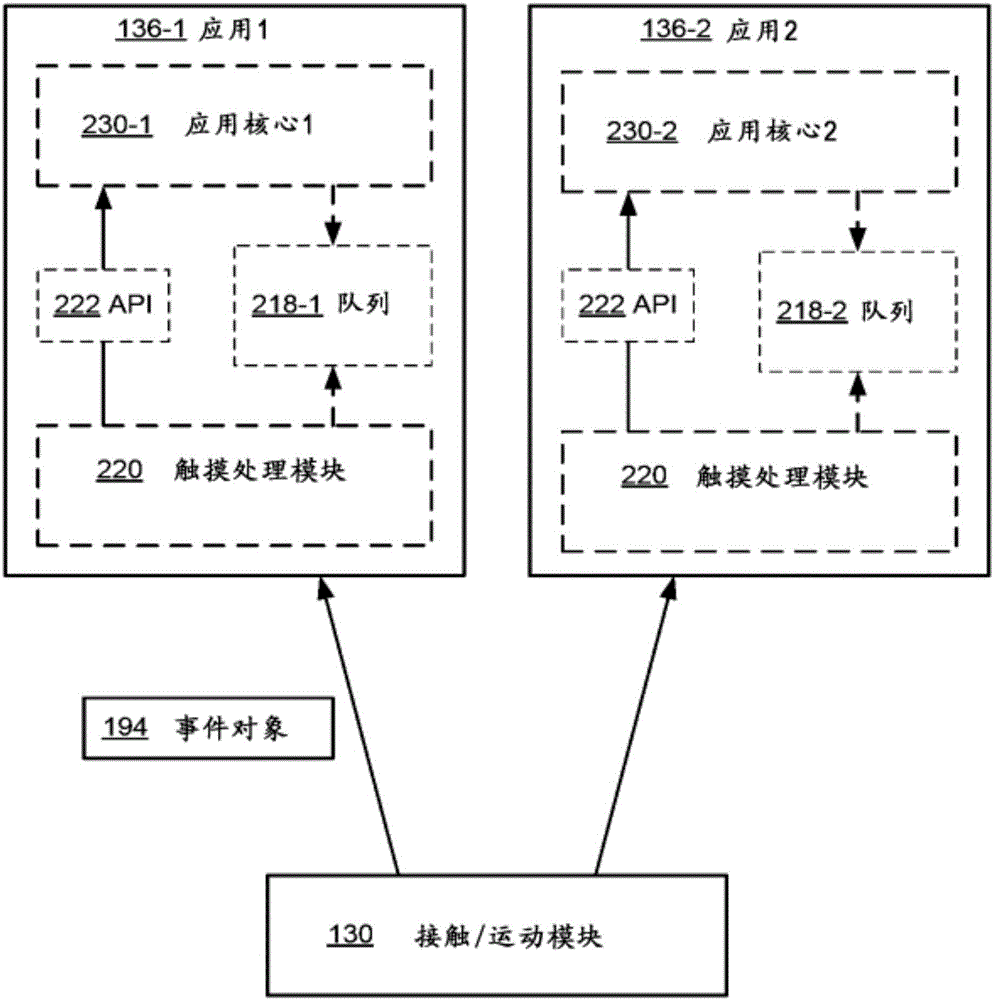

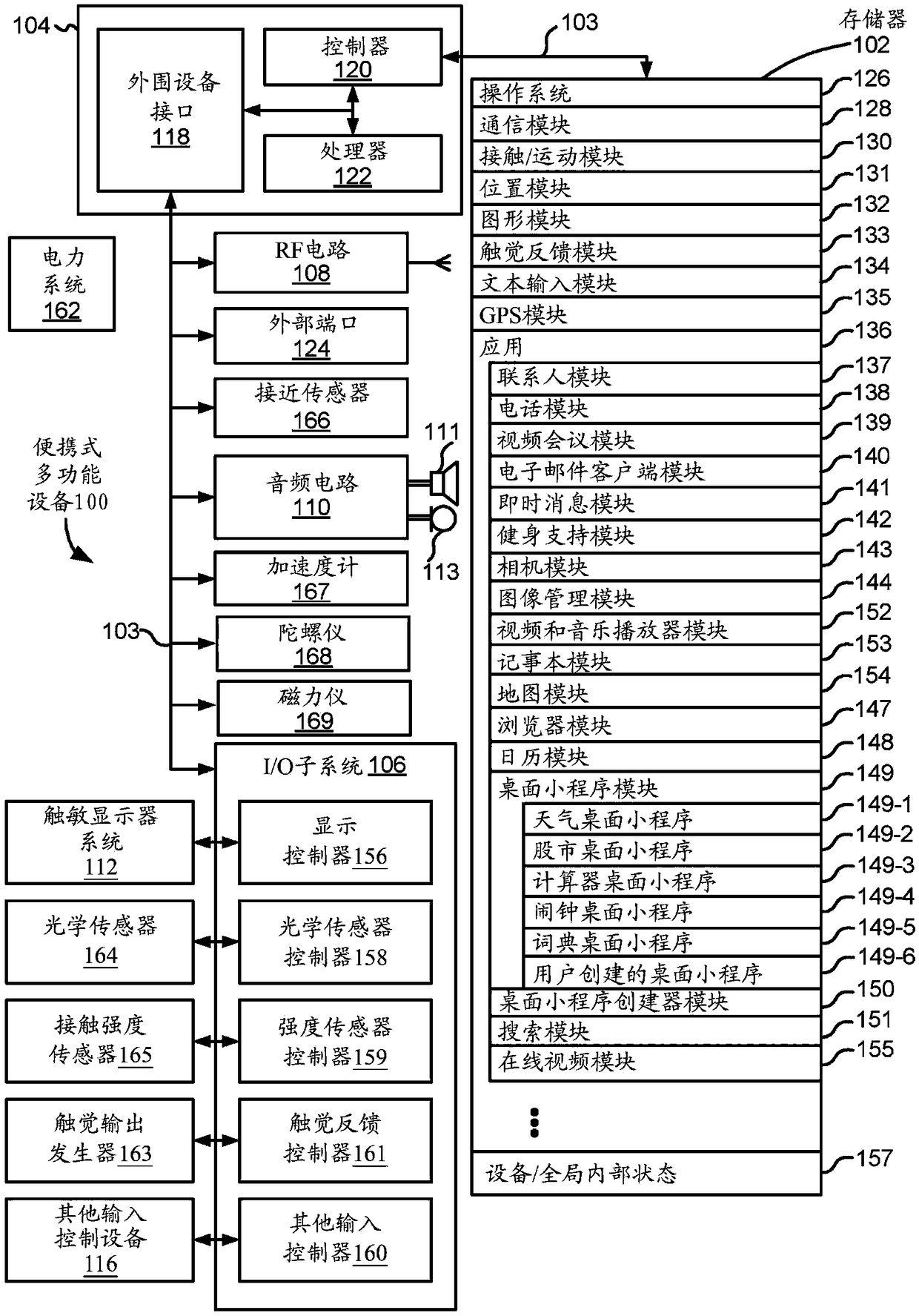

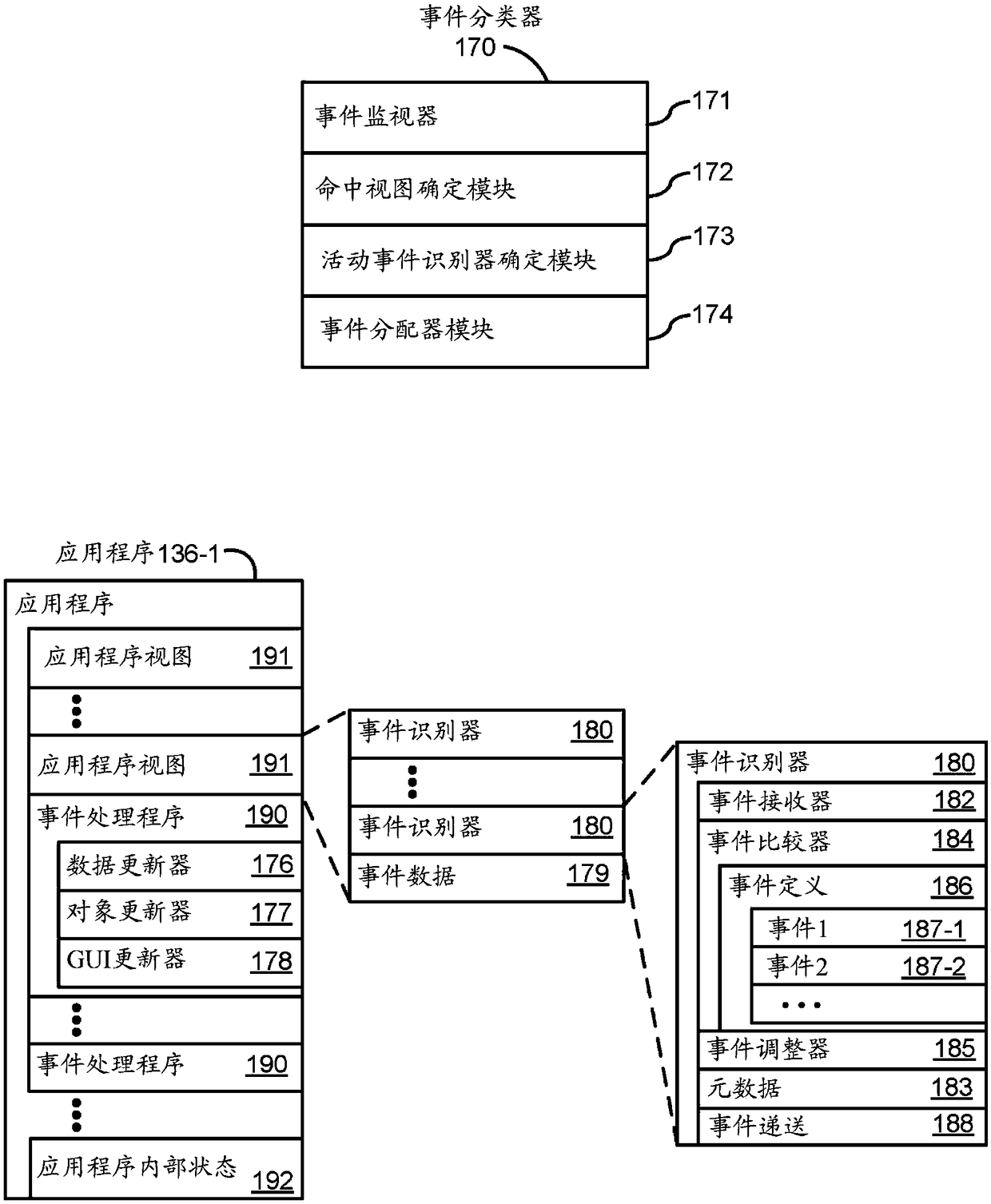

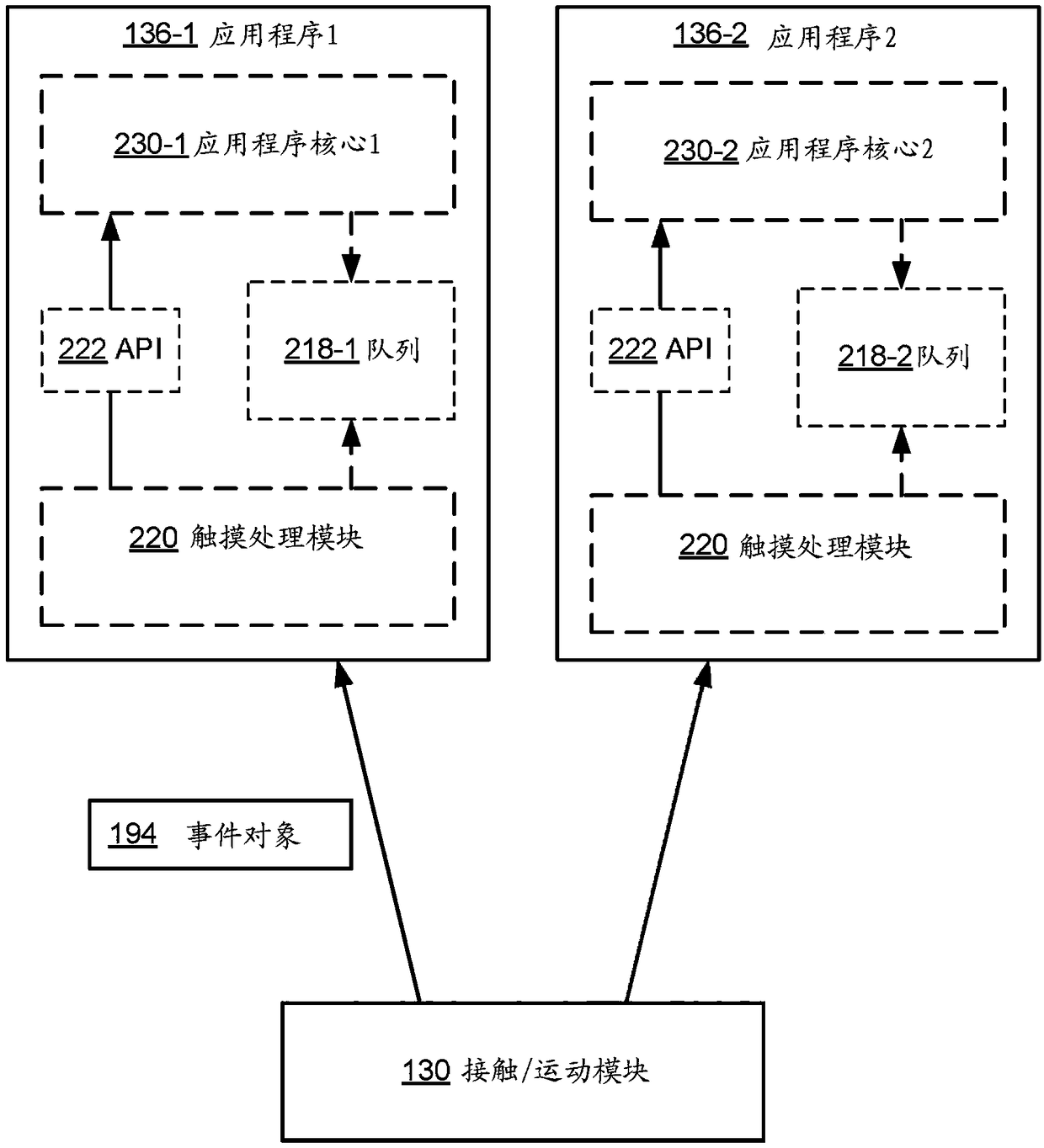

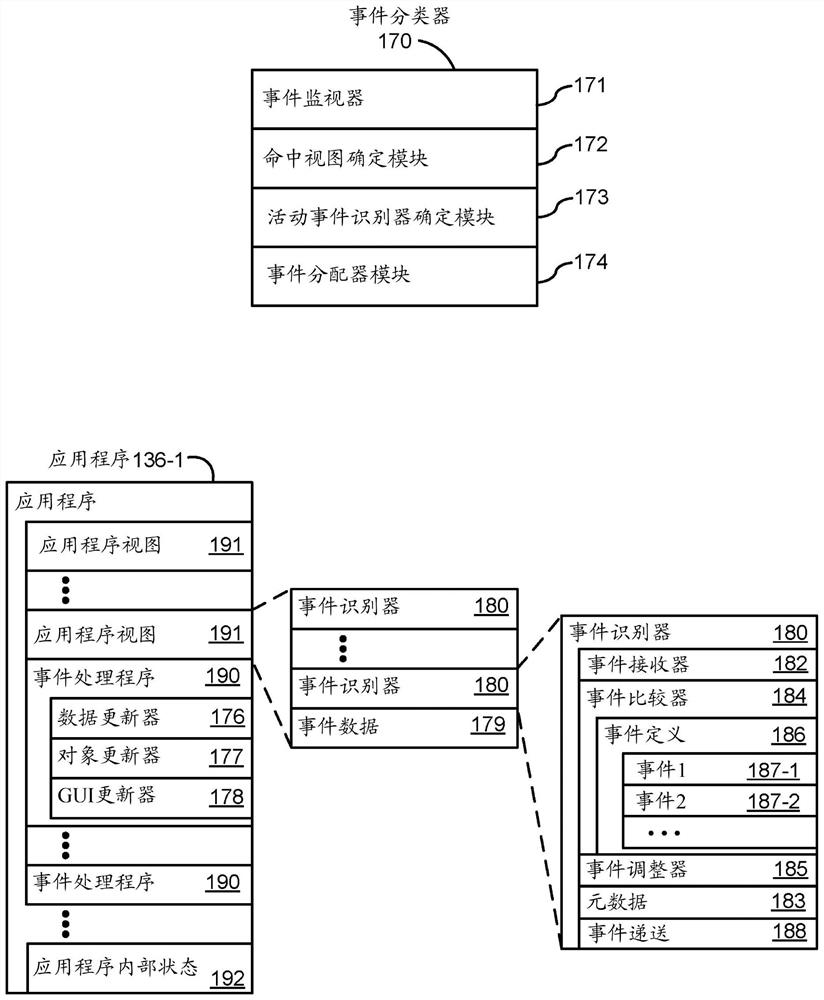

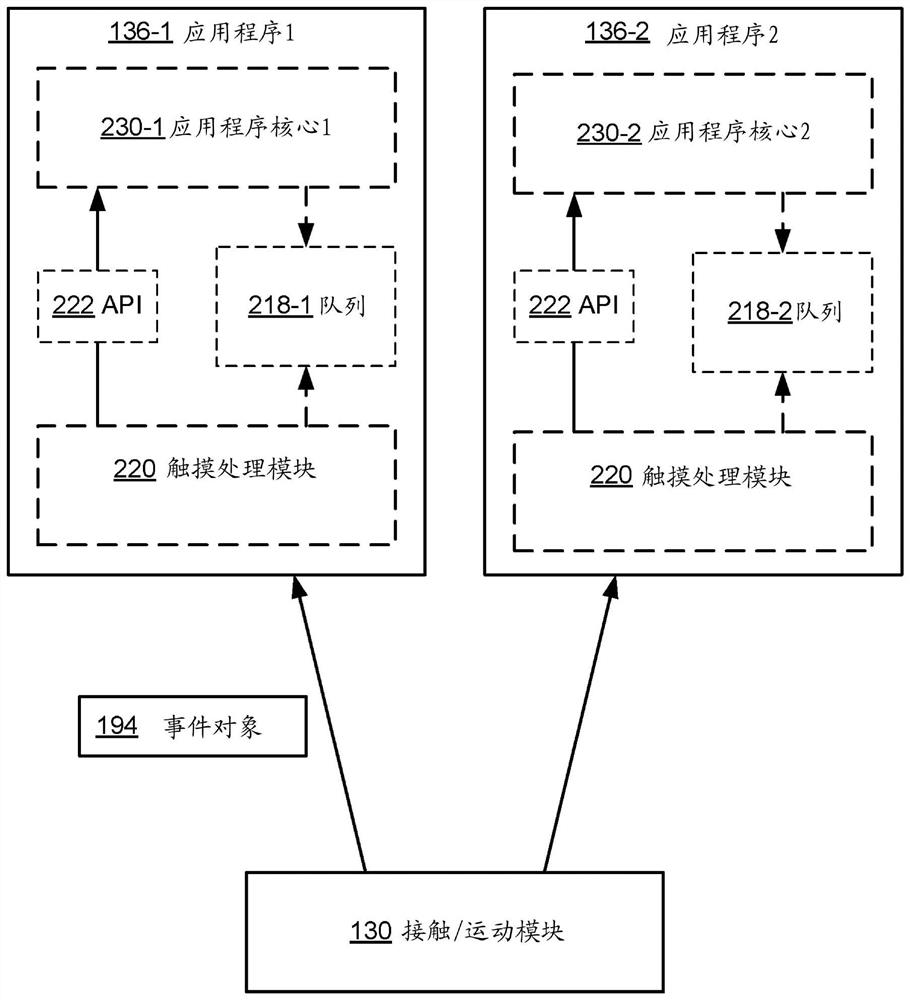

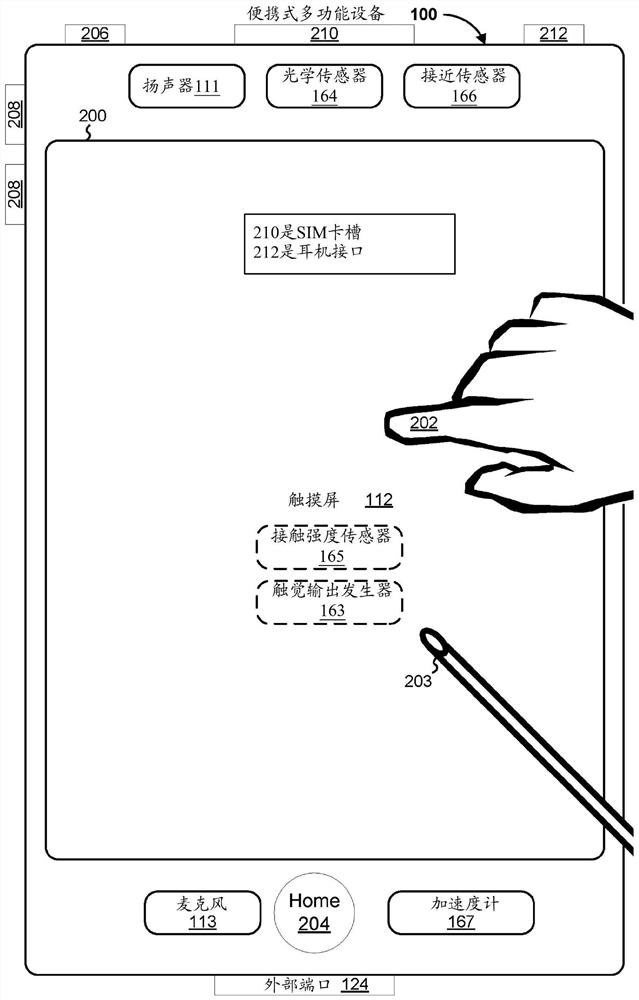

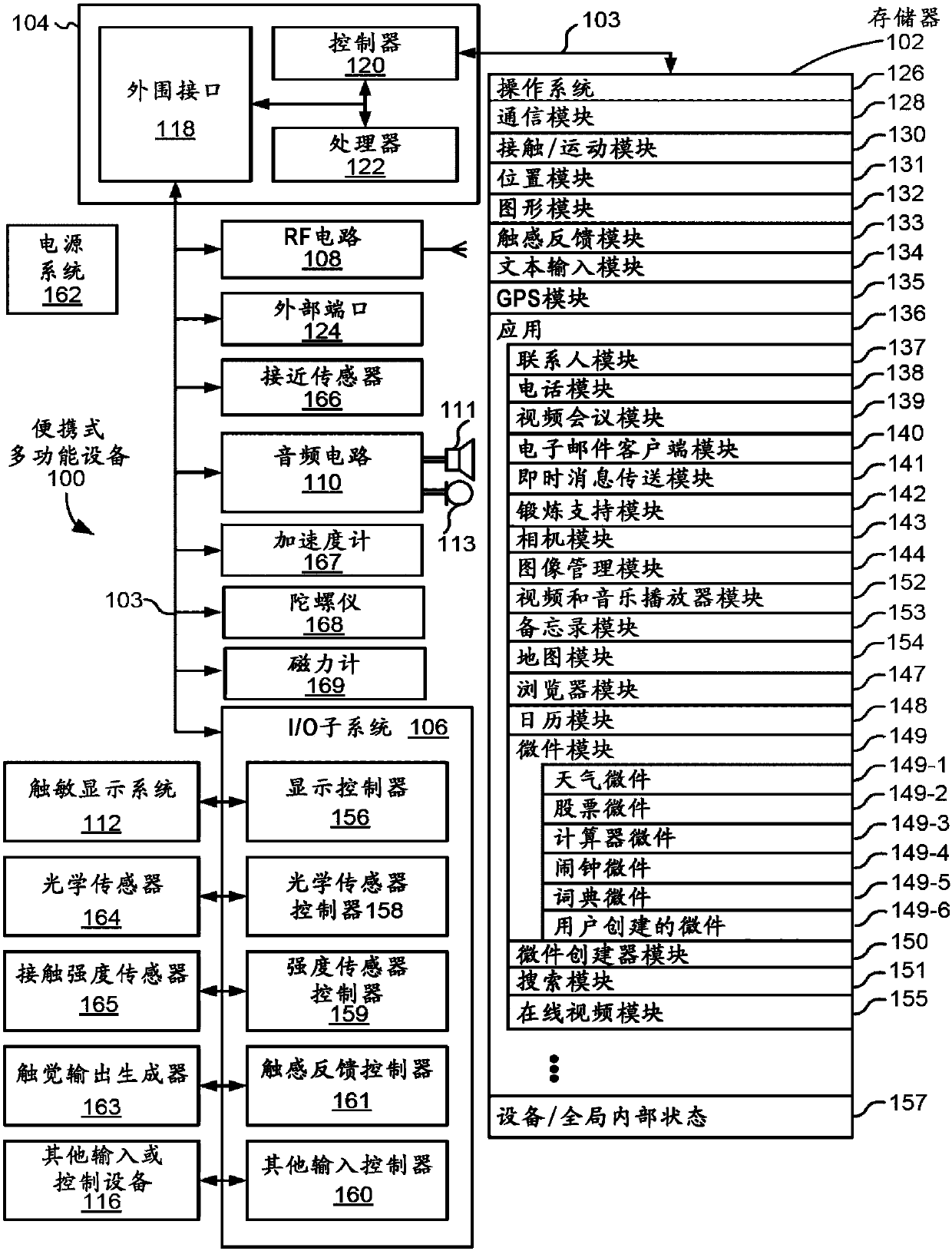

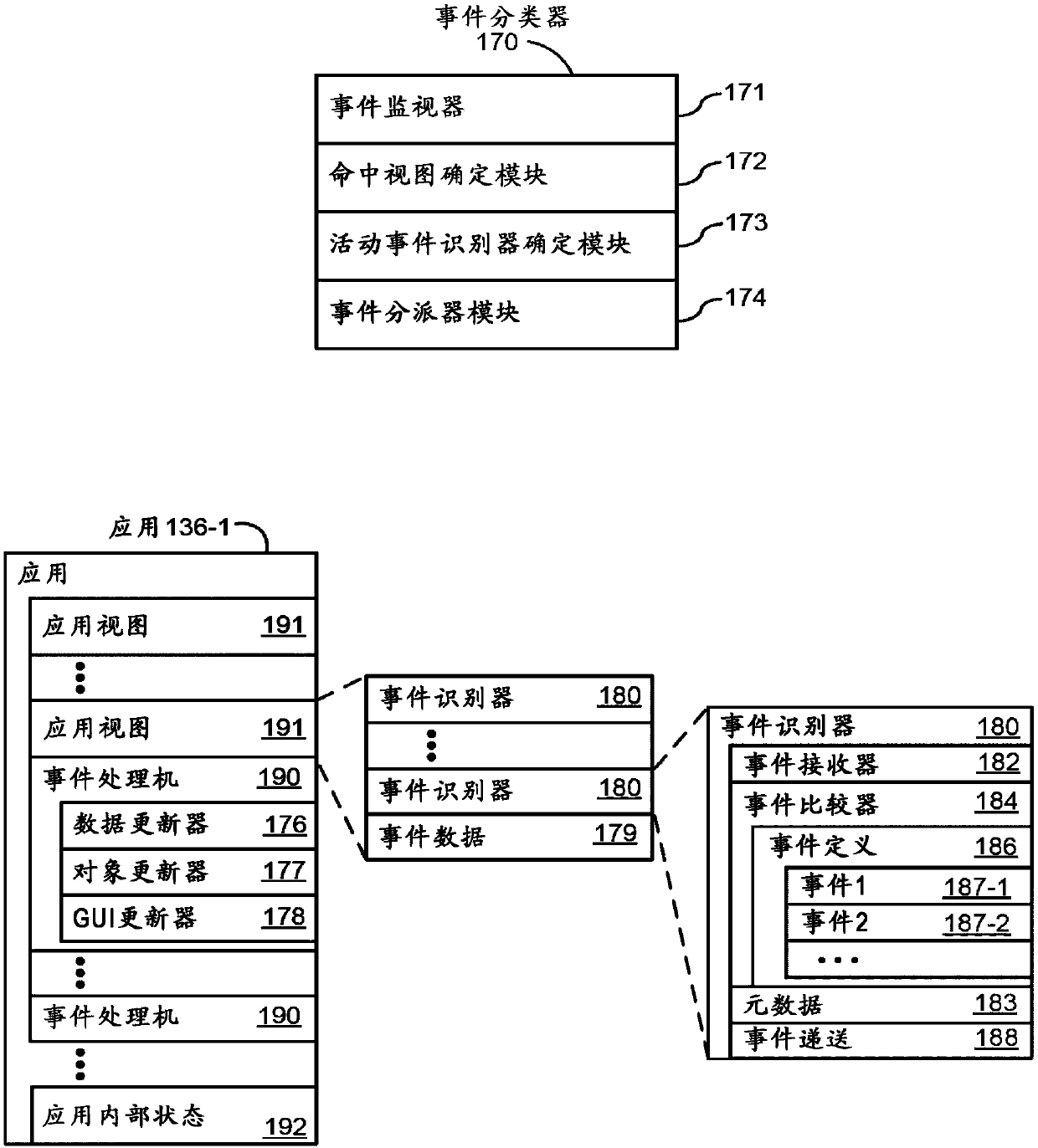

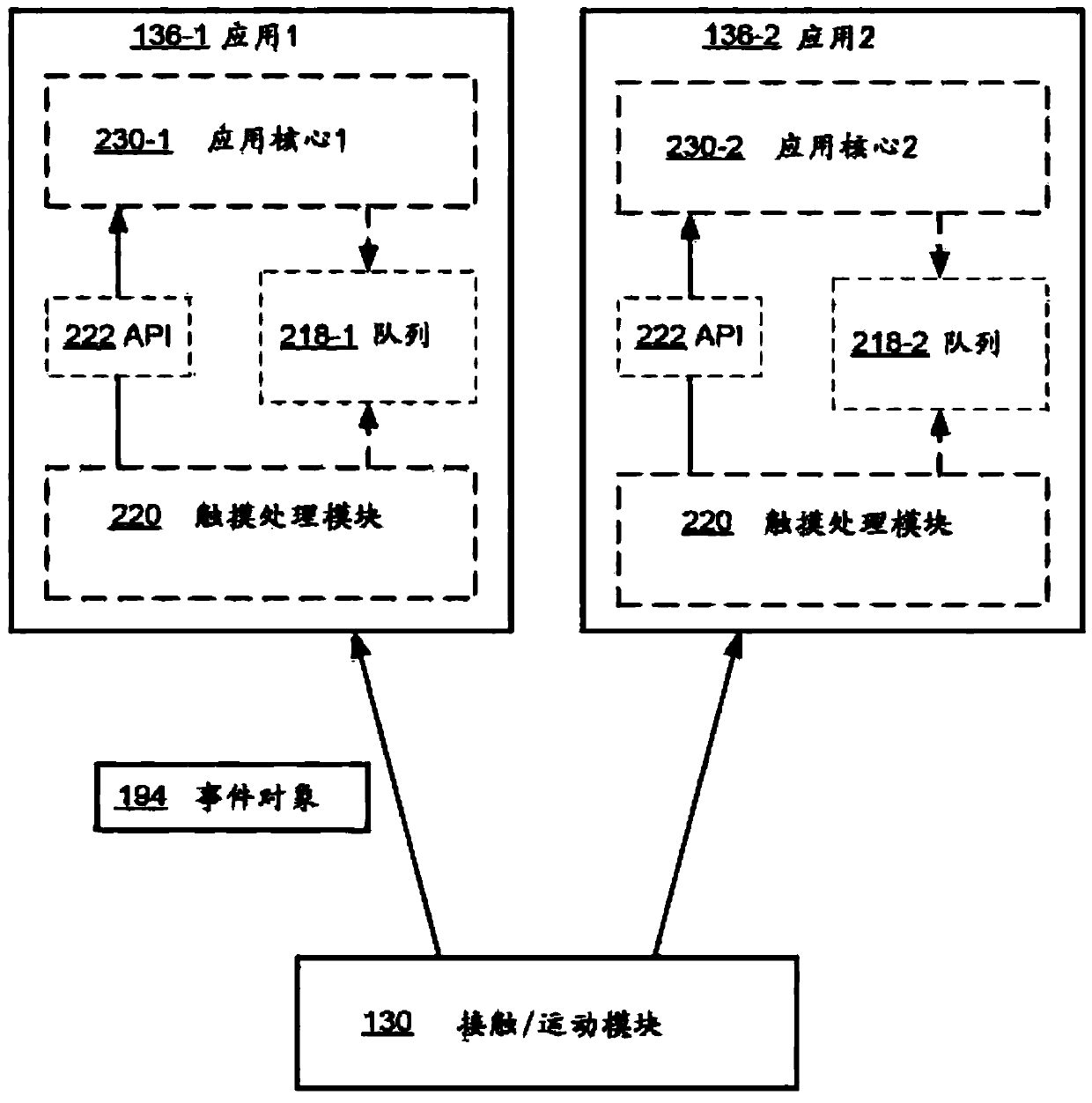

Device and method for processing touch inputs based on their intensities

PendingCN106843711AImprove satisfactionReduce dosagePower supply for data processingInput/output processes for data processingDisplay deviceHuman–computer interaction

A device and method for processing touch inputs based on their intensities are provided. An electronic device with a display, a touch-sensitive surface, and one or more sensors to detect intensity of contacts with the touch-sensitive surface: displays a first user interface of a first software application, the first user interface including a plurality of user interface objects, a first user interface object of the plurality of user interface objects being associated with an application-independent set of predefined instructions for preview operations; detects a first portion of an input by a contact while a focus selector is over the first user interface object, in the plurality of user interface objects, on the display; and in response to detecting the first portion of the input and in accordance with a determination that the first portion of the input satisfies predefined criteria, executes the application-independent set of predefined instructions for preview operations.

Owner:APPLE INC

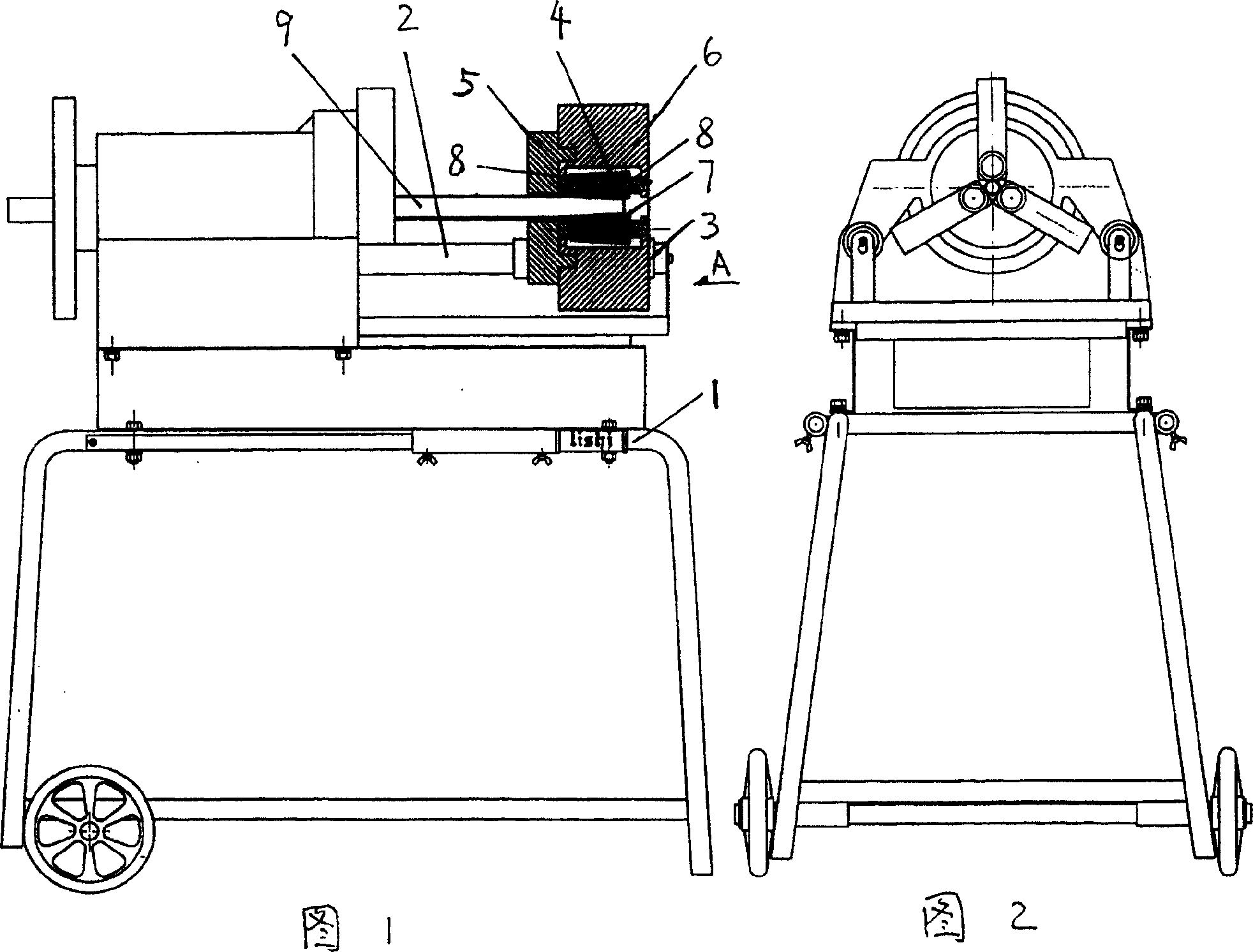

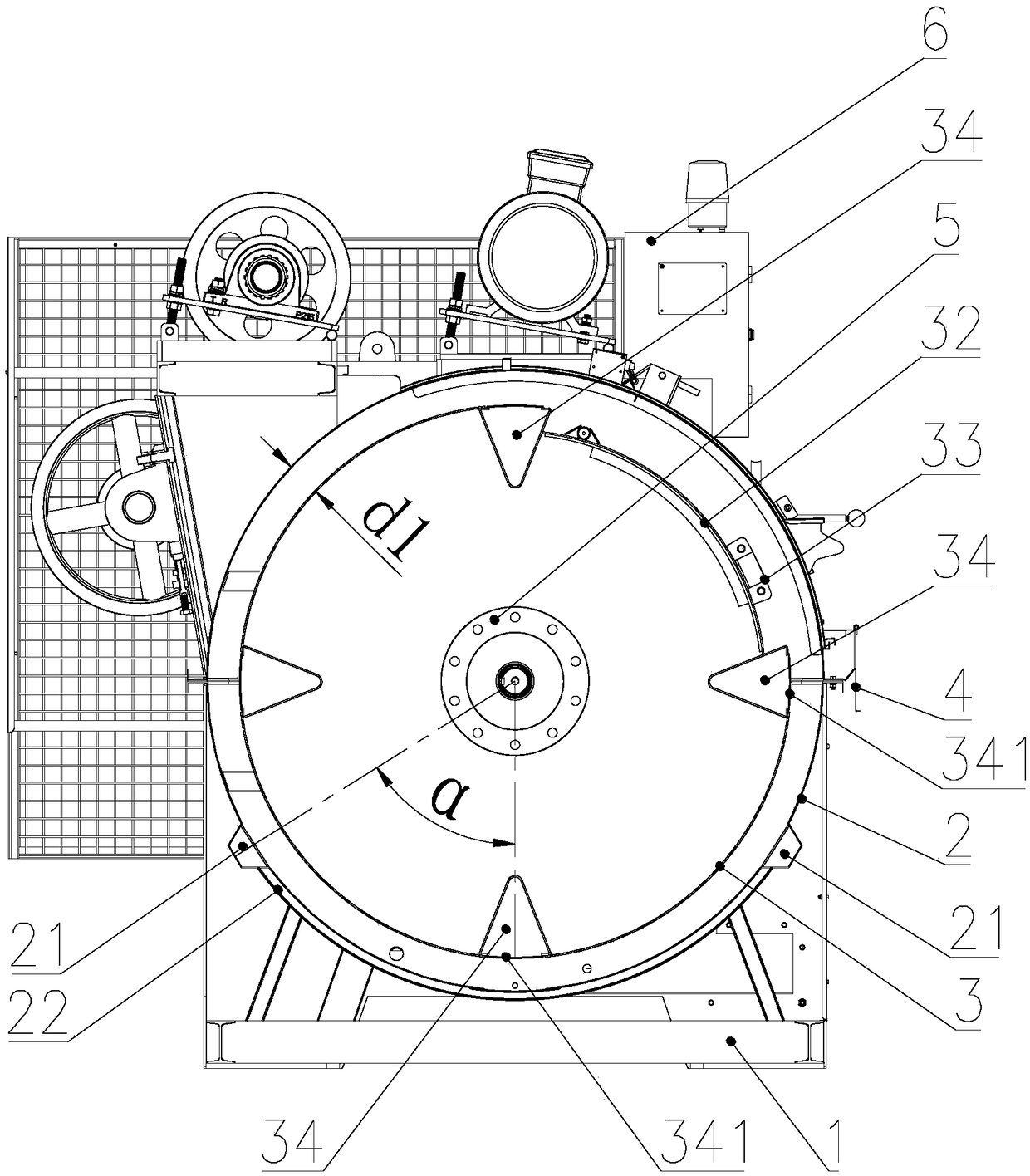

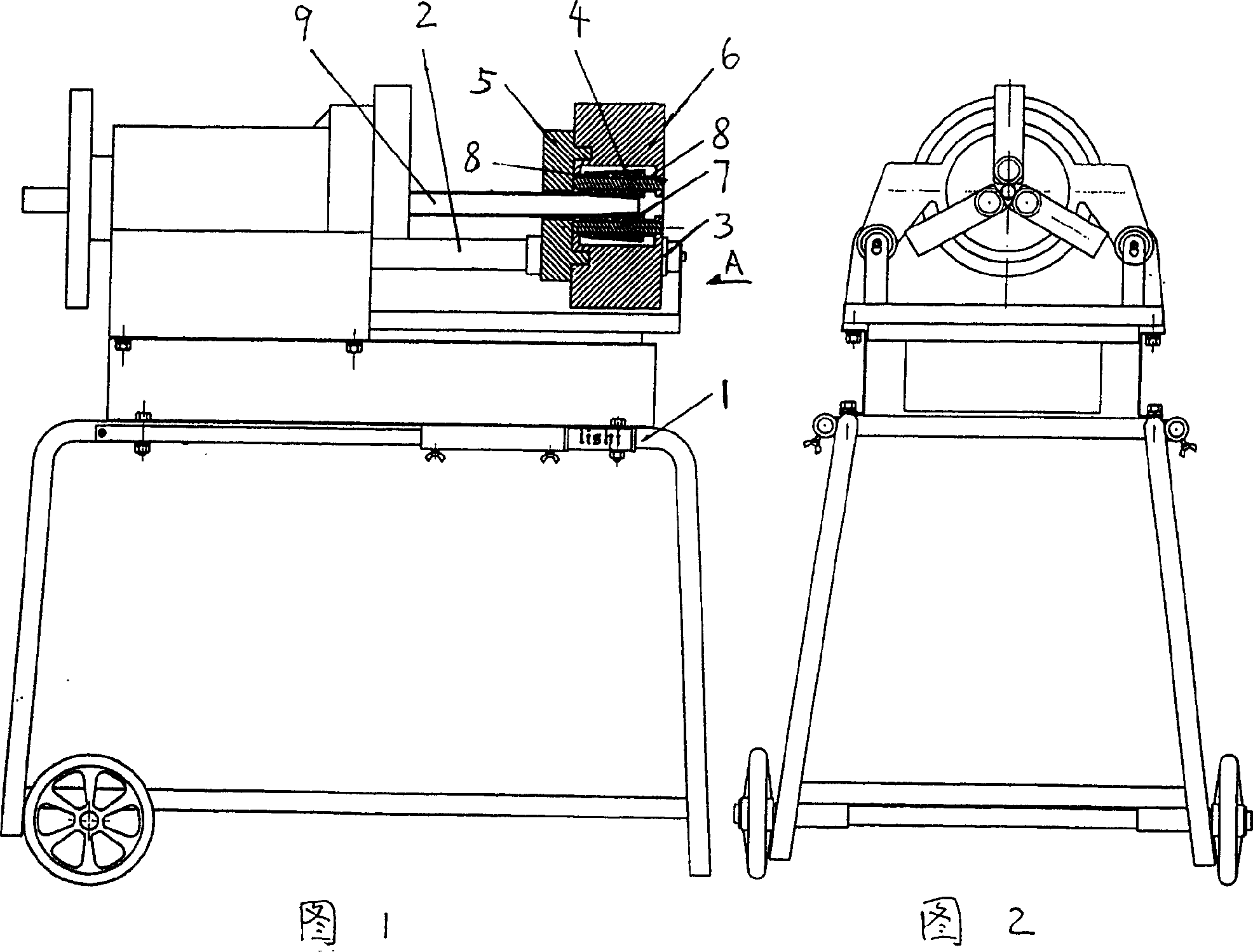

Pipeline thread rolling and processing method and roll machine

The invention is a pipeline thread rolling method and the roller, nipping the pipeline on the pipe nipping mechanism driven by the electric machine, there is a thread rolling mechanism placed in the working front, there are rolling wheels in the rolling mechanism, the pipeline rotates and enters in between three rolling wheels coaxially and distributed at 120 deg. central angle in the thread rolling mechanism, rolling into a thread shape, the pipeline thread roller is composed of base, electric machine, reducer, guide pile locating mechanism and workpiece clamping mechanism, there is a sliding frame on the two guide piles and the there is a thread rolling mechanism set on the sliding frame, compared with existing techniques, it has the characters of reasonable structure, smooth thread, high precision, etc.

Owner:崔莹莹

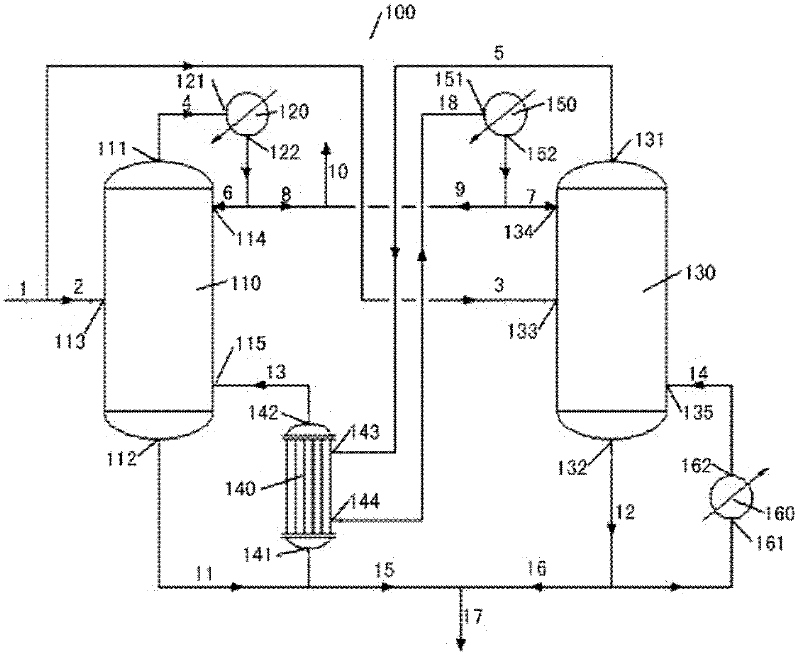

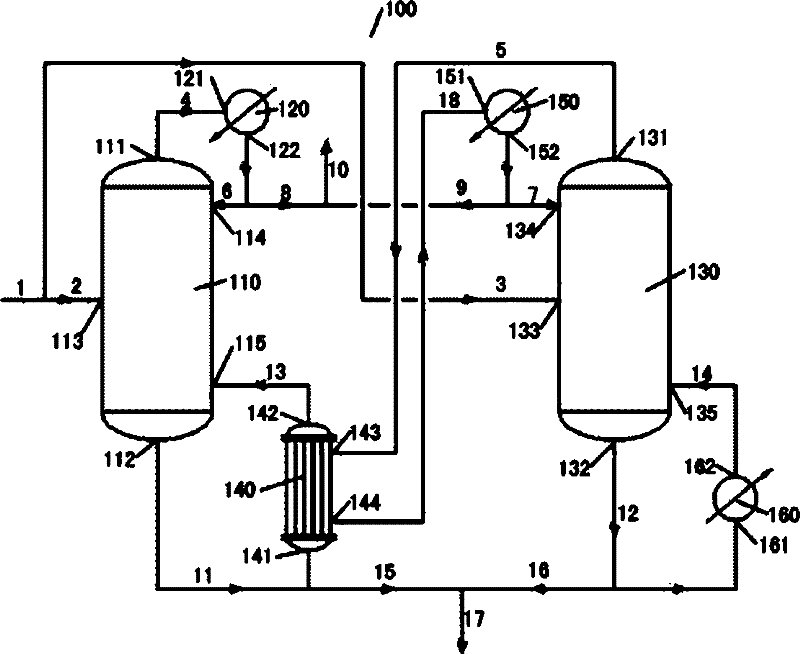

Trichlorosilane rectification system

ActiveCN102649019ASmall diameterReduce processing powerChemical industryFractional distillationReboilerEngineering

The invention discloses a trichlorosilane rectification system, which comprises a first rectification tower, a condenser, a second rectification tower, a first reboiler, a subcooler and a second reboiler, wherein an inlet of the condenser is connected with the first upper outlet of the first rectification tower, an outlet of the condenser is connected with a first return flow opening of the first rectification tower, a first inlet of the first reboiler is connected with a first lower outlet of the first rectification tower, a first outlet of the first reboiler is connected with a first air return opening of the first rectification tower, a second inlet of the first reboiler is connected with a second upper outlet of the second rectification tower, a second outlet of the first reboiler is connected with a second return flow opening of the second rectification tower, an inlet of the subcooler is connected with a second outlet of the first reboiler, an outlet of the subcooler is connected with a second return flow opening of the second rectification tower, an inlet of the second reboiler is connected with a second lower outlet of the second rectification tower, and an outlet of the second reboiler is connected with a second air return opening of the second rectification tower. The trichlorosilane rectification system according to the embodiment of the invention has the advantages that the produced trichlorosilane quality is high, the energy consumption is low, the equipment investment is low, and the like.

Owner:CHINA ENFI ENGINEERING CORPORATION +1

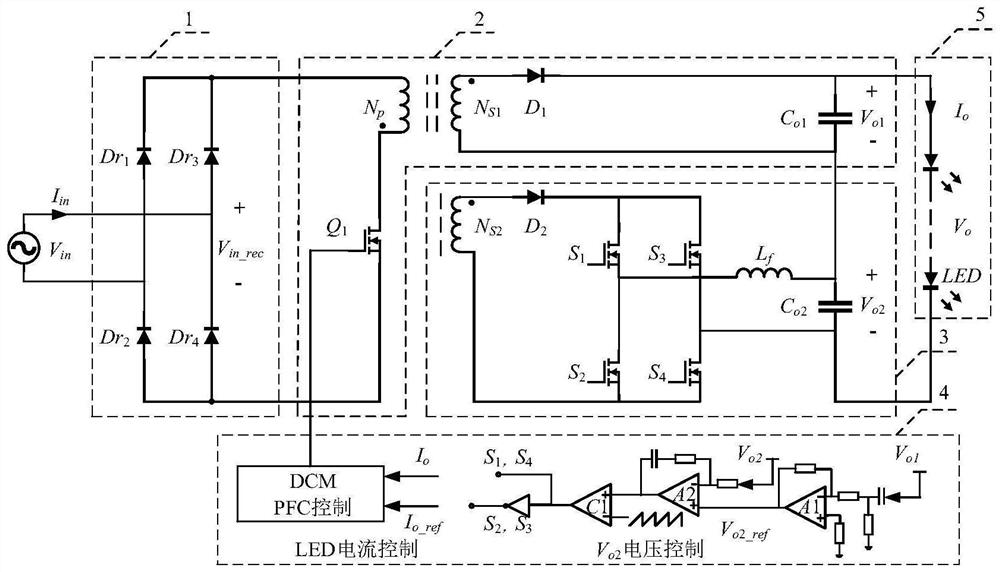

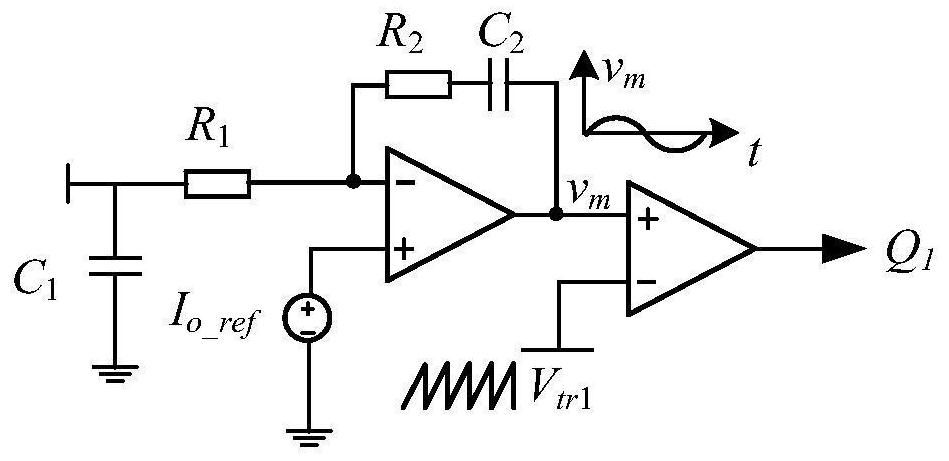

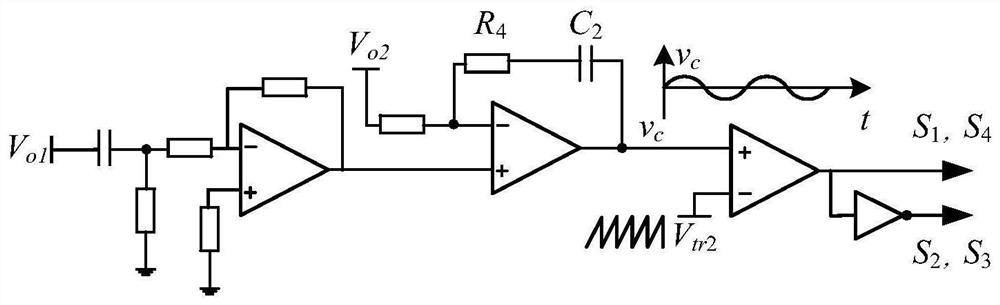

LED driving power supply based on Flyback ripple suppression type non-electrolytic capacitor

ActiveCN112055448AMeet the drive characteristic requirementsExtended service lifeElectrical apparatusFull bridgePower factor

The invention discloses an LED driving power supply based on a Flyback ripple suppression type non-electrolytic capacitor, and belongs to the technical field of power generation, power transformationor power distribution. A drive circuit comprises a full-bridge rectification filter circuit, a PFC conversion circuit, a ripple suppression unit and a control unit. An isolated single-stage AC-DC converter, an PFC converter based on the Flyback circuit and a ripple suppression converter based on the full-bridge circuit are combined to form the LED drive circuit, the ripple power decoupling is achieved, an electrolytic capacitor is prevented from being used, and meanwhile, the number of energy cycles in the circuit is reduced. The problem that the output voltage is out of control due to the fact that the instantaneous input power is lower than the required output power in a short time is solved, the requirements of no electrolytic capacitor, high power factor and high conversion efficiencyare met, the service life of the LED driving power supply is prolonged, and the stability and efficiency of the LED driving power supply are improved.

Owner:SOUTHEAST UNIV

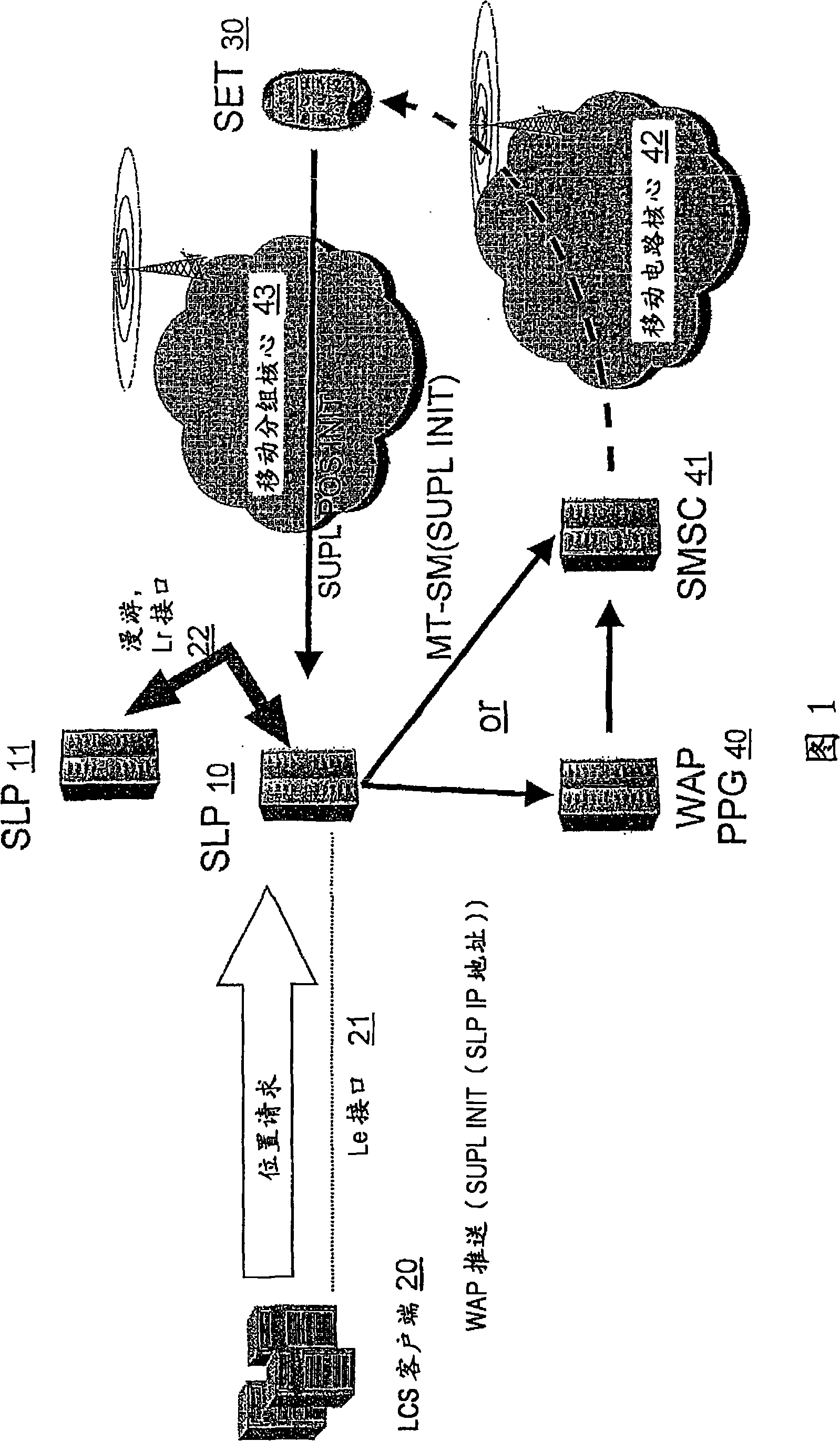

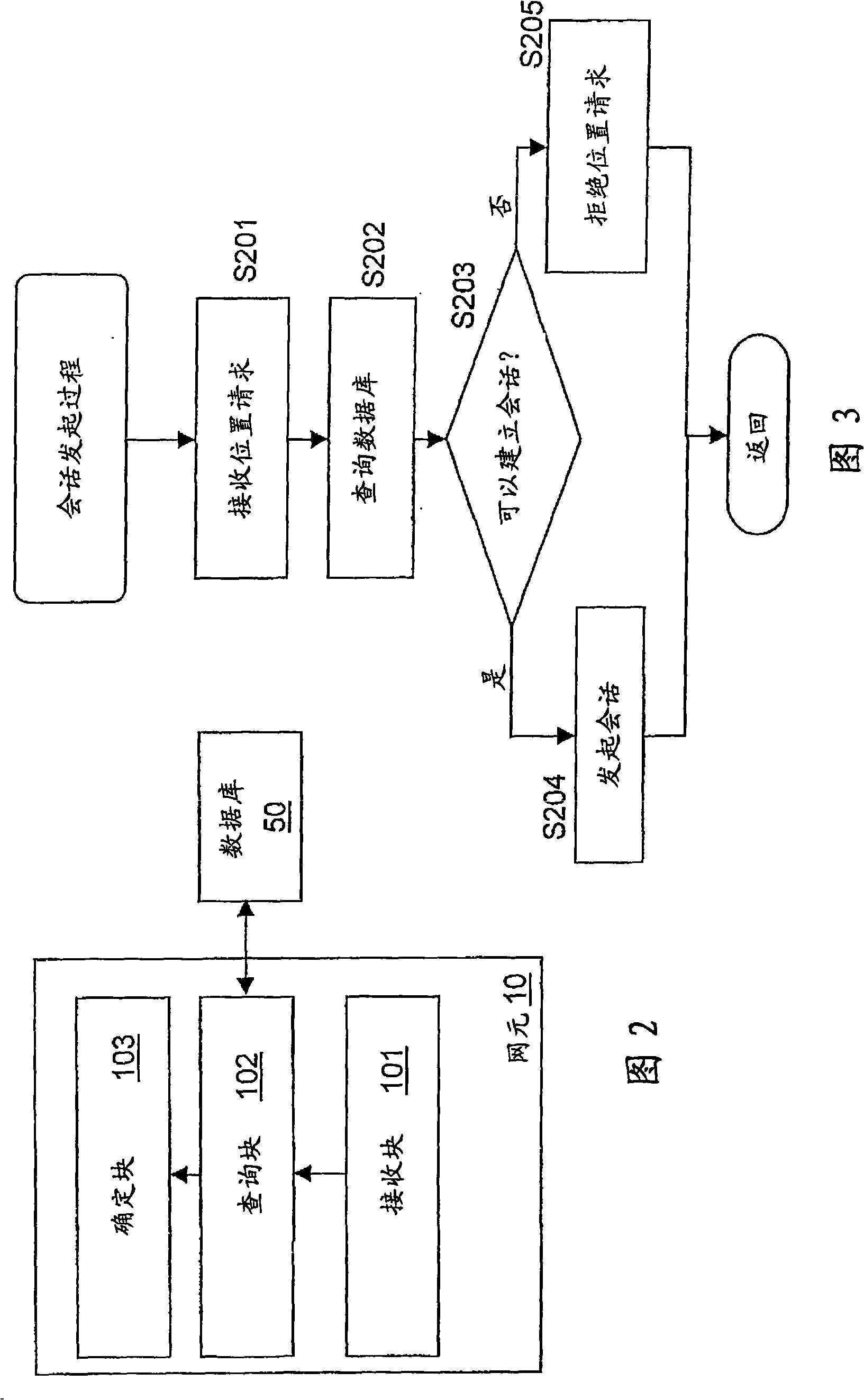

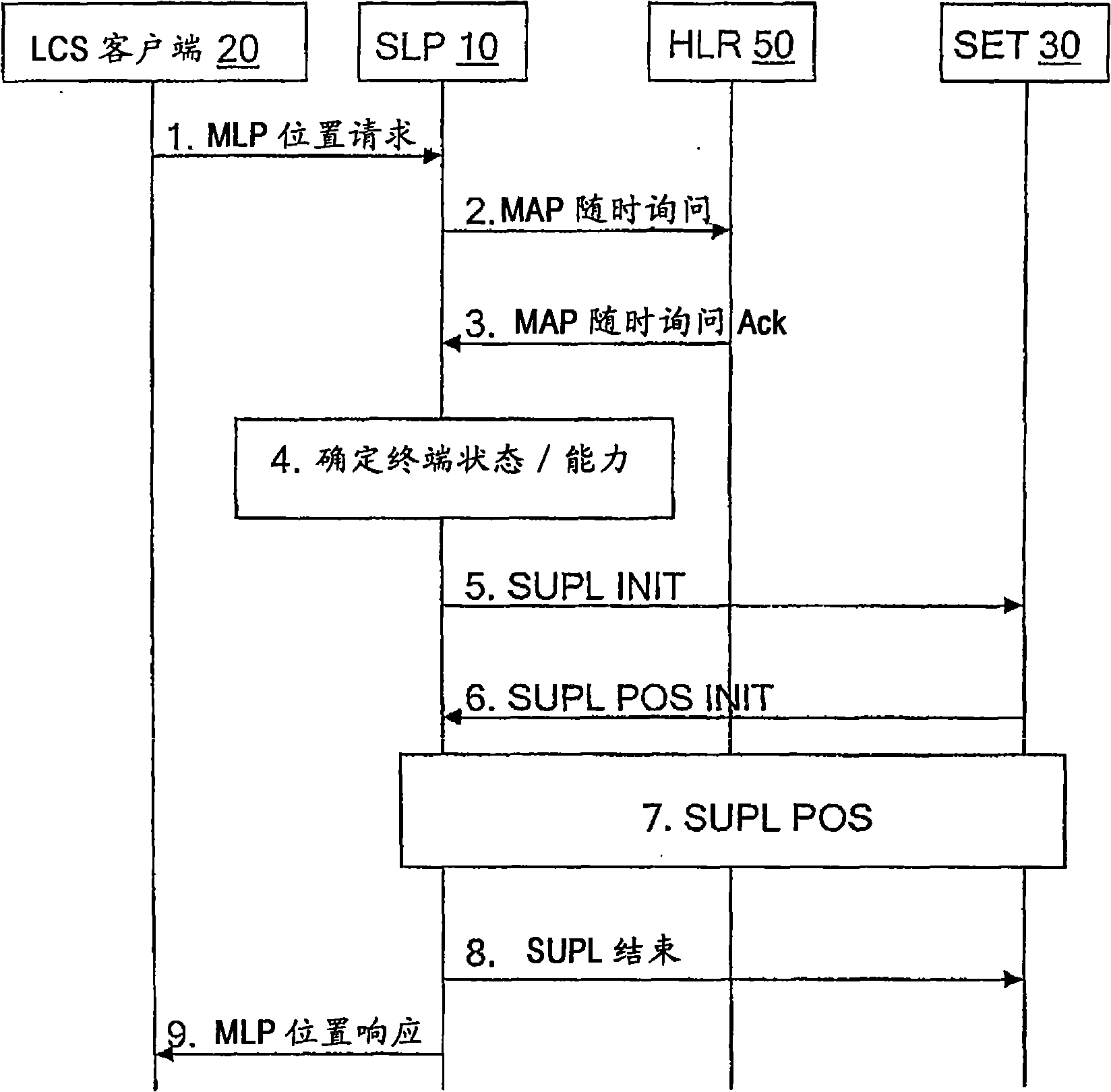

Terminal status discovery in secure user plane location positioning procedure

InactiveCN101361392AReduce processing powerShort response timeRadio/inductive link selection arrangementsNetwork data managementTelecommunicationsSecure User Plane Location

When receiving a location request for a mobile terminal, the status of the mobile terminal is discovered before initiating a SUPL positioning procedure. For this purpose, status information is retrieved from a database or location register outside SUPL and it is determined from the status information whether a SUPL session can be established with the mobile terminal.

Owner:NOKIA CORP

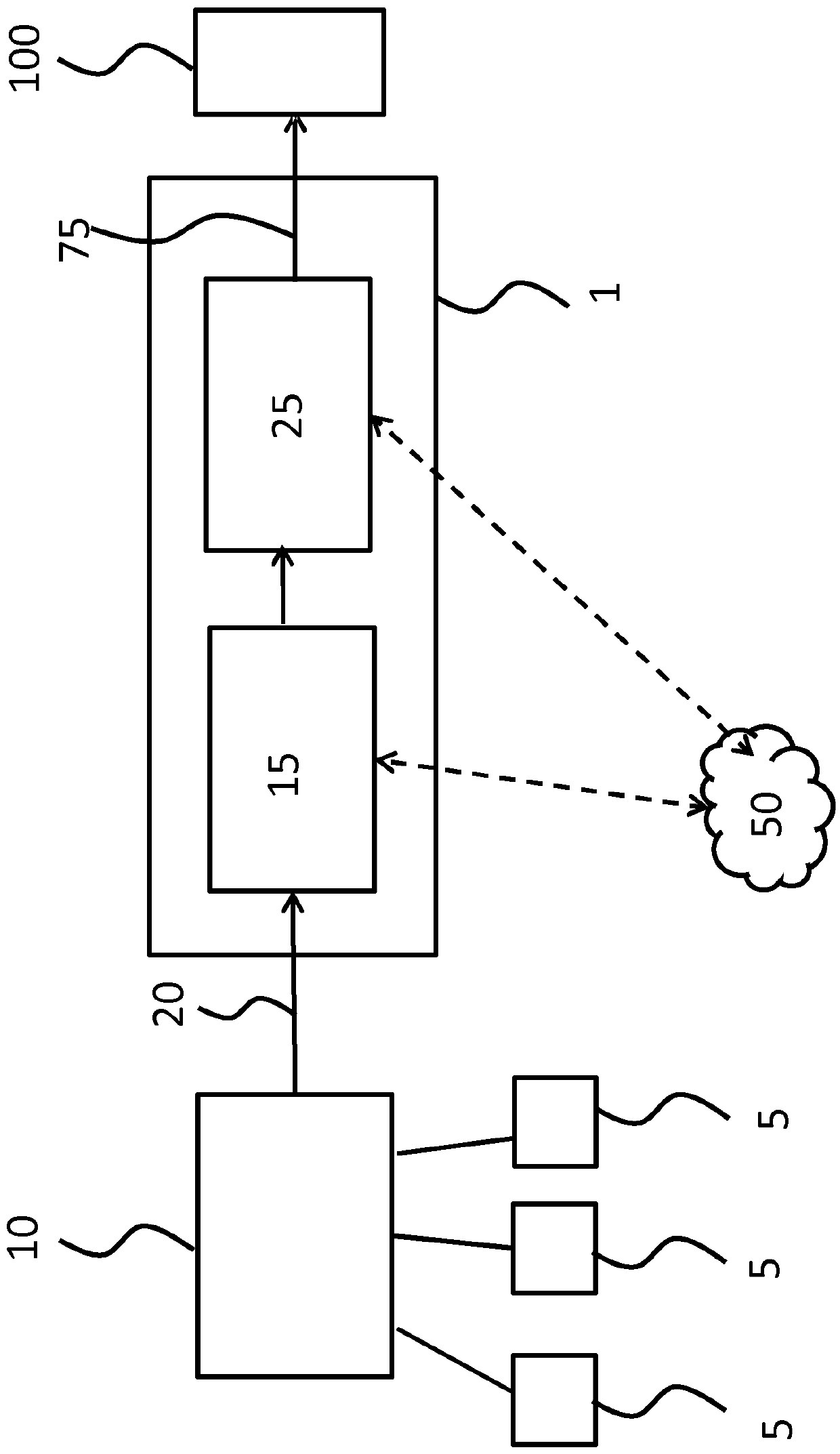

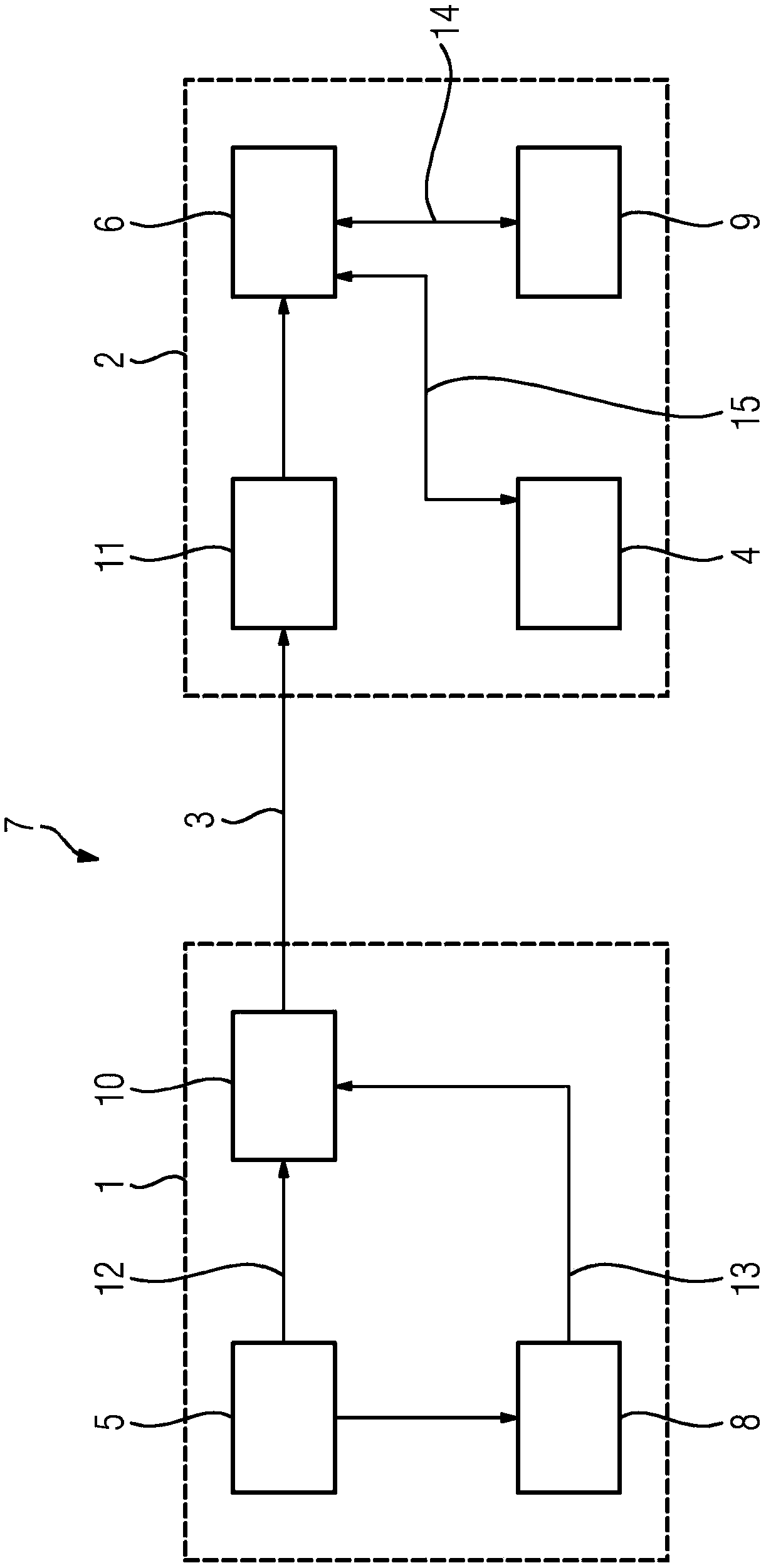

System and method for monitoring activities of daily living of person

ActiveCN109843173ALow costReduce processing powerDrug and medicationsMedical automated diagnosisControl signalControl system

Presented is a system and method for monitoring activities of daily living, ADLs, of a person within an environment containing an object that is controllable by the person via a control system. The system comprises a data collection unit adapted to obtain control data from the control system, the control data being based on one or more control signals generated by the control system for controlling the object. A data analysis unit is 5 adapted to determine an ADL event of the person based on the obtained control data.

Owner:SIGNIFY HLDG BV

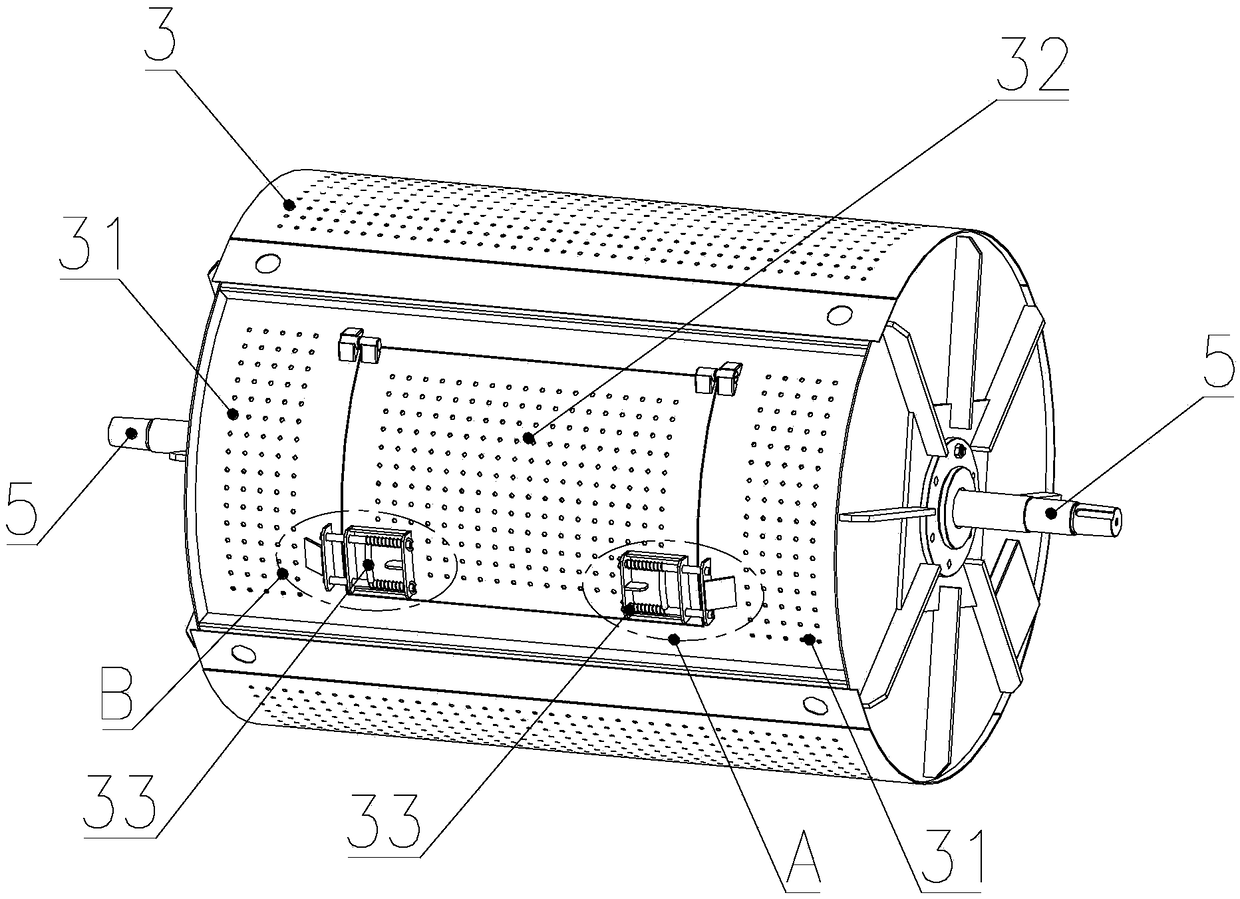

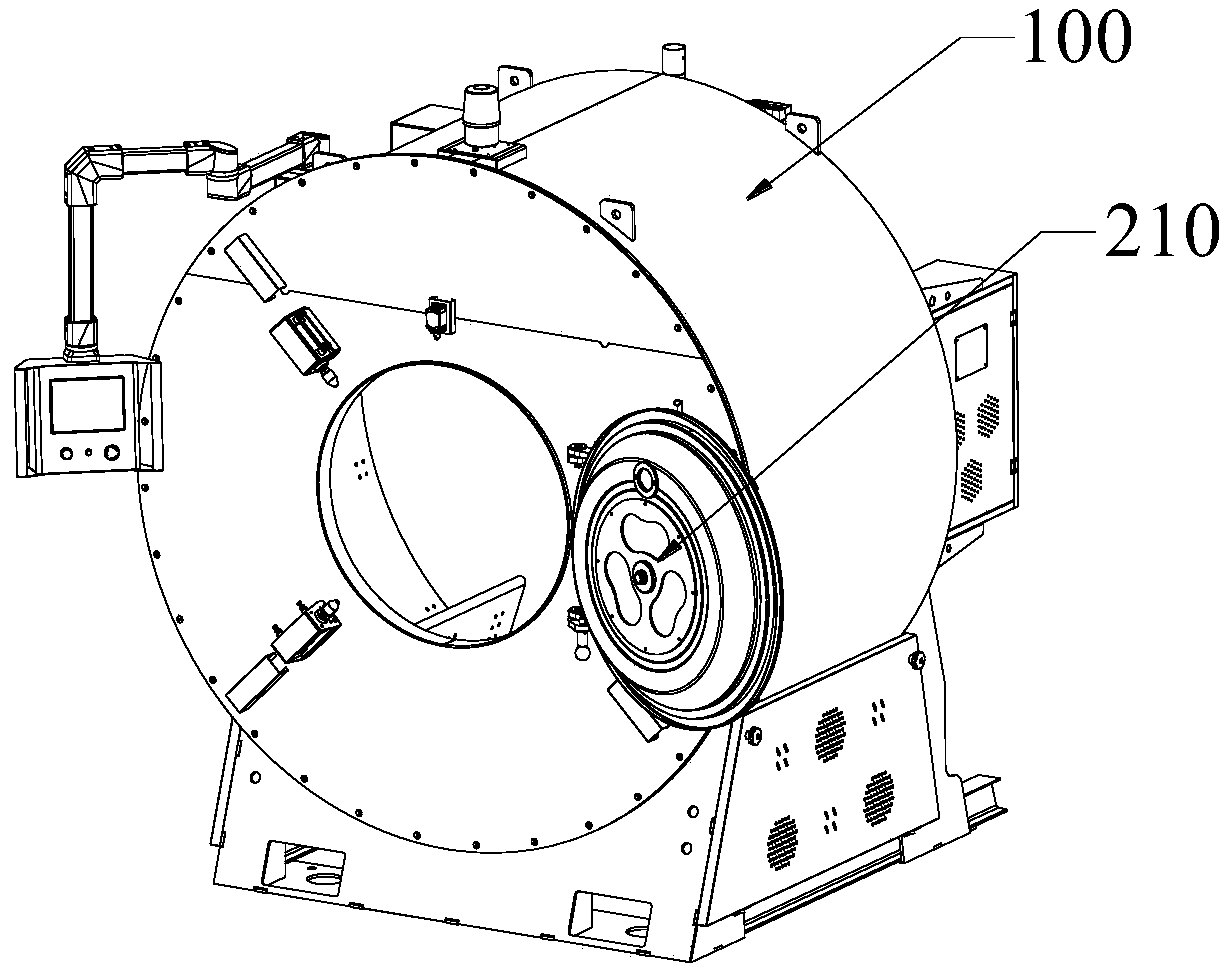

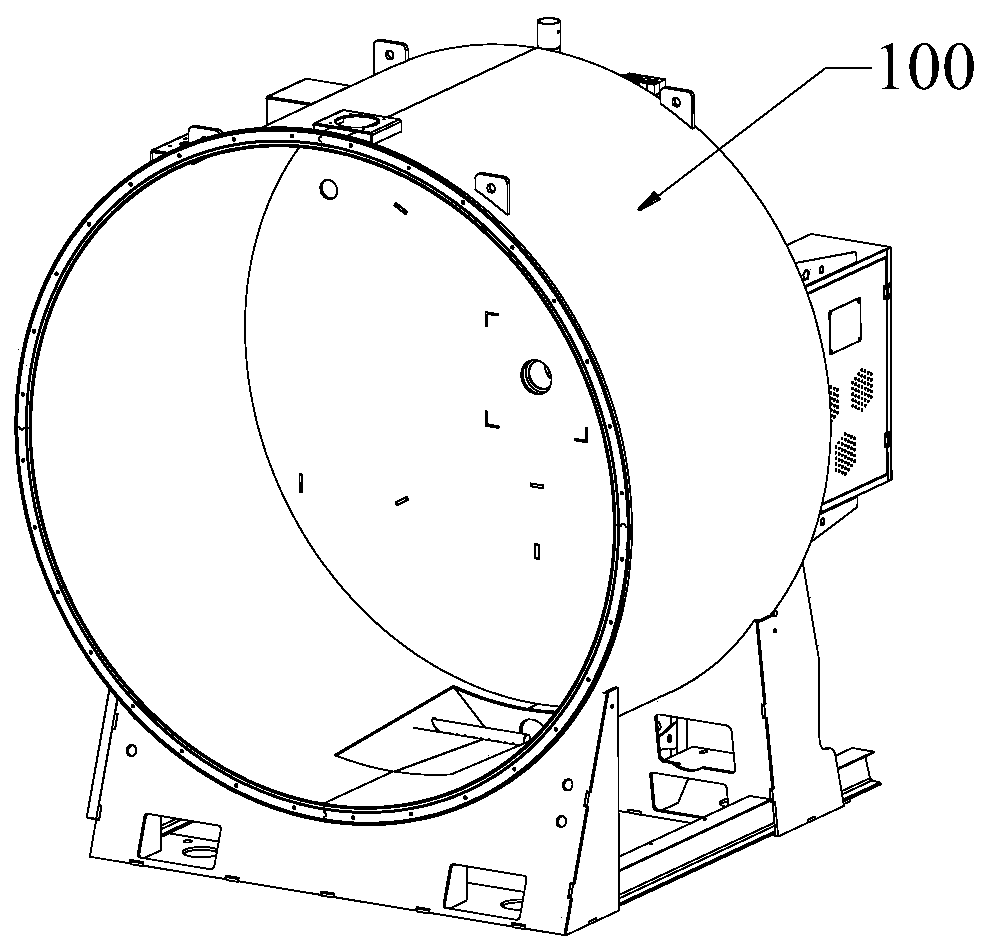

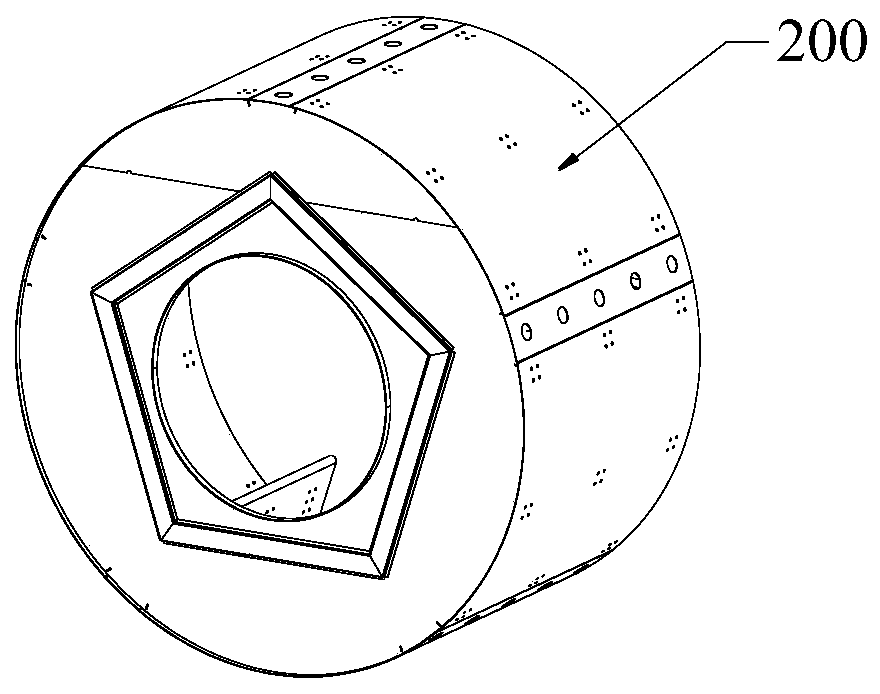

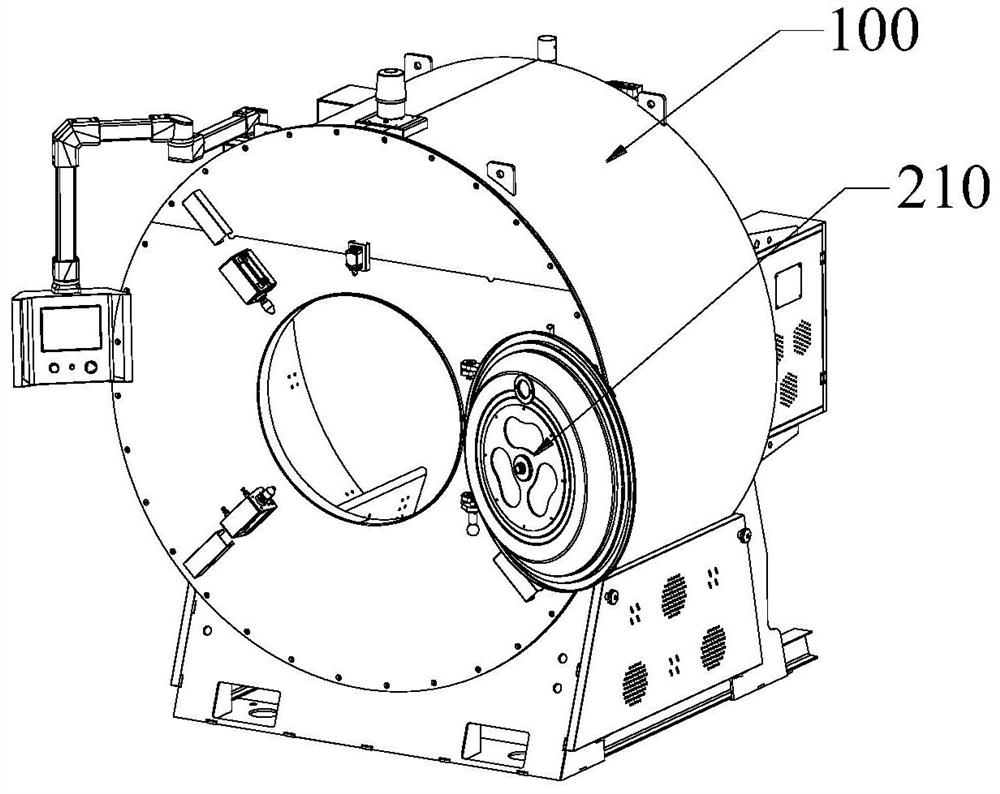

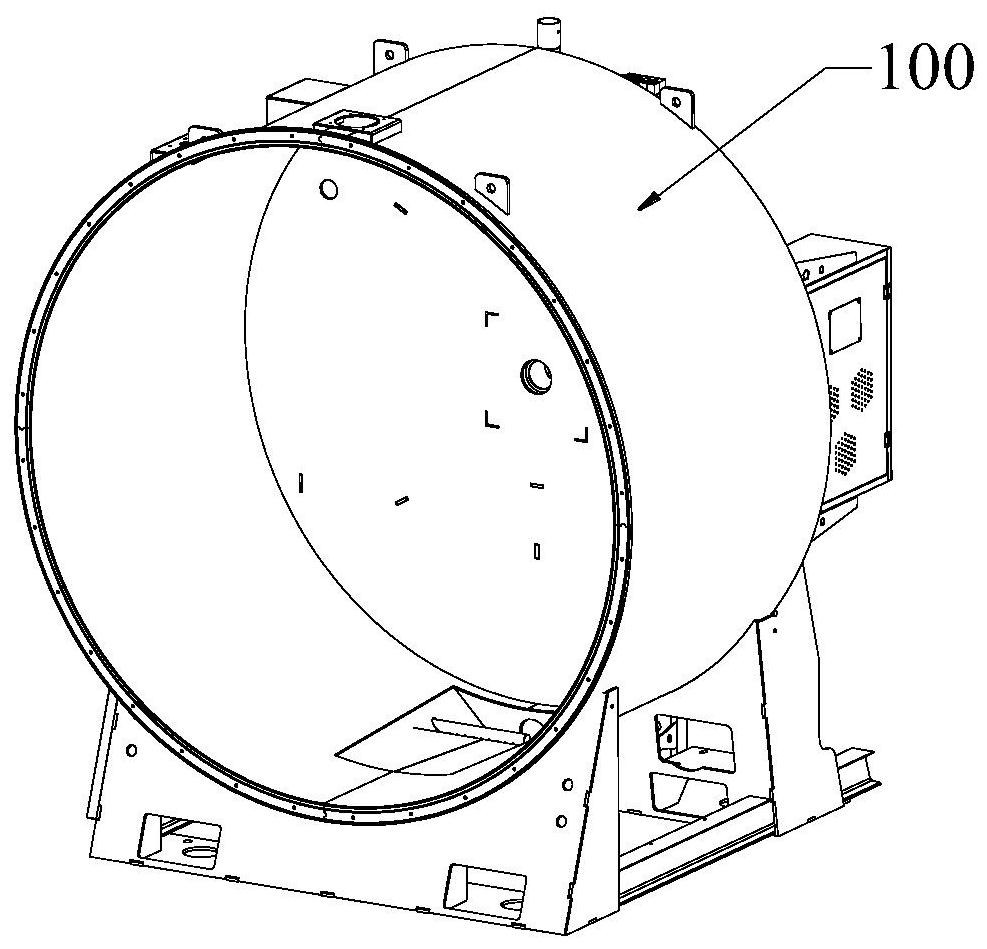

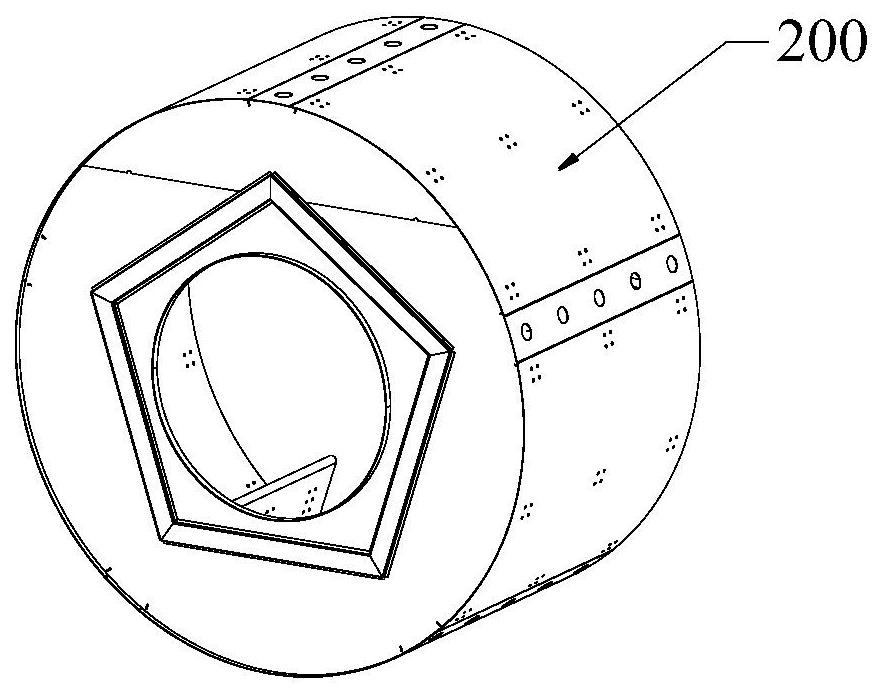

Water-saving washer

PendingCN108823896AImprove structural strengthReduce the chance of damageOther washing machinesWashing machine with receptaclesWater savingEngineering

The invention relates to the field of industrial washers, in particular to a water-saving washer. The water-saving washer comprises an outer barrel, an inner barrel and a rotation shaft, wherein the outer barrel, the inner barrel and the rotation shaft which is driven by a motor are arranged on a washer base; the inner barrel is coaxially and horizontally arranged in the outer barrel and driven bythe rotation shaft to rotate; multiple small holes are formed in the peripheral wall of the inner barrel, and an inner door is arranged on the peripheral wall of the inner barrel; an outer door corresponding to the inner door is arranged on the peripheral wall of the outer barrel; a locking buckle is arranged on the inner barrel and used for locking the inner door; an inner sink area is arrangedon the peripheral wall of the inner barrel; the inner door is mounted on the inner sink area. According to the technical scheme, the width of the space between the inner barrel and the outer barrel isreduced to the maximum extent, the actual usage amount of water for washing clothes is reduced, the intensity of subsequent sewage treatment and environment pollution are reduced, and the industrialproduction cost is also reduced.

Owner:广州市信宏洗衣机械有限公司

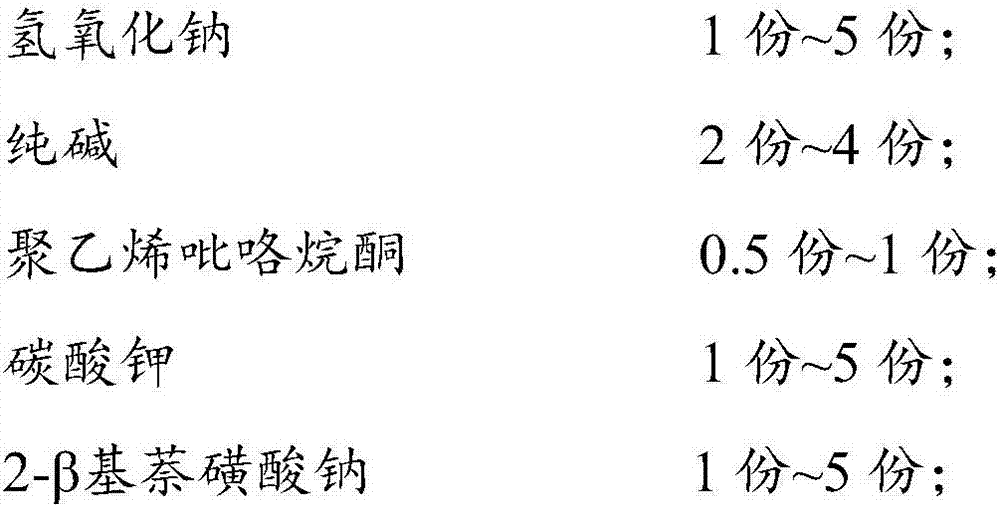

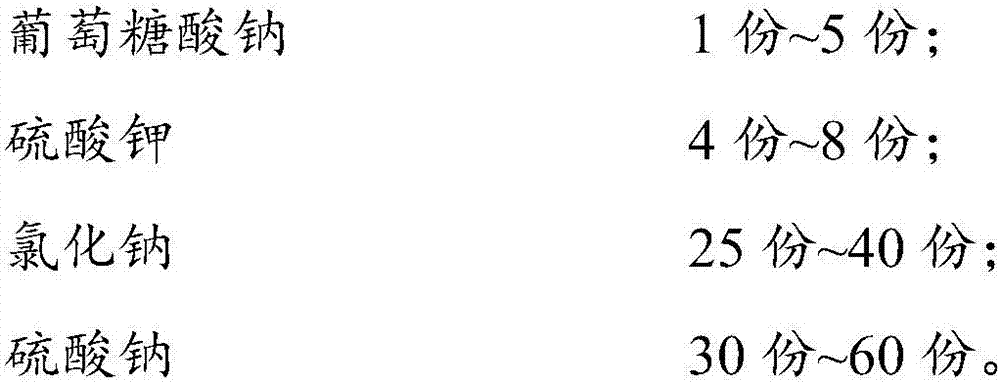

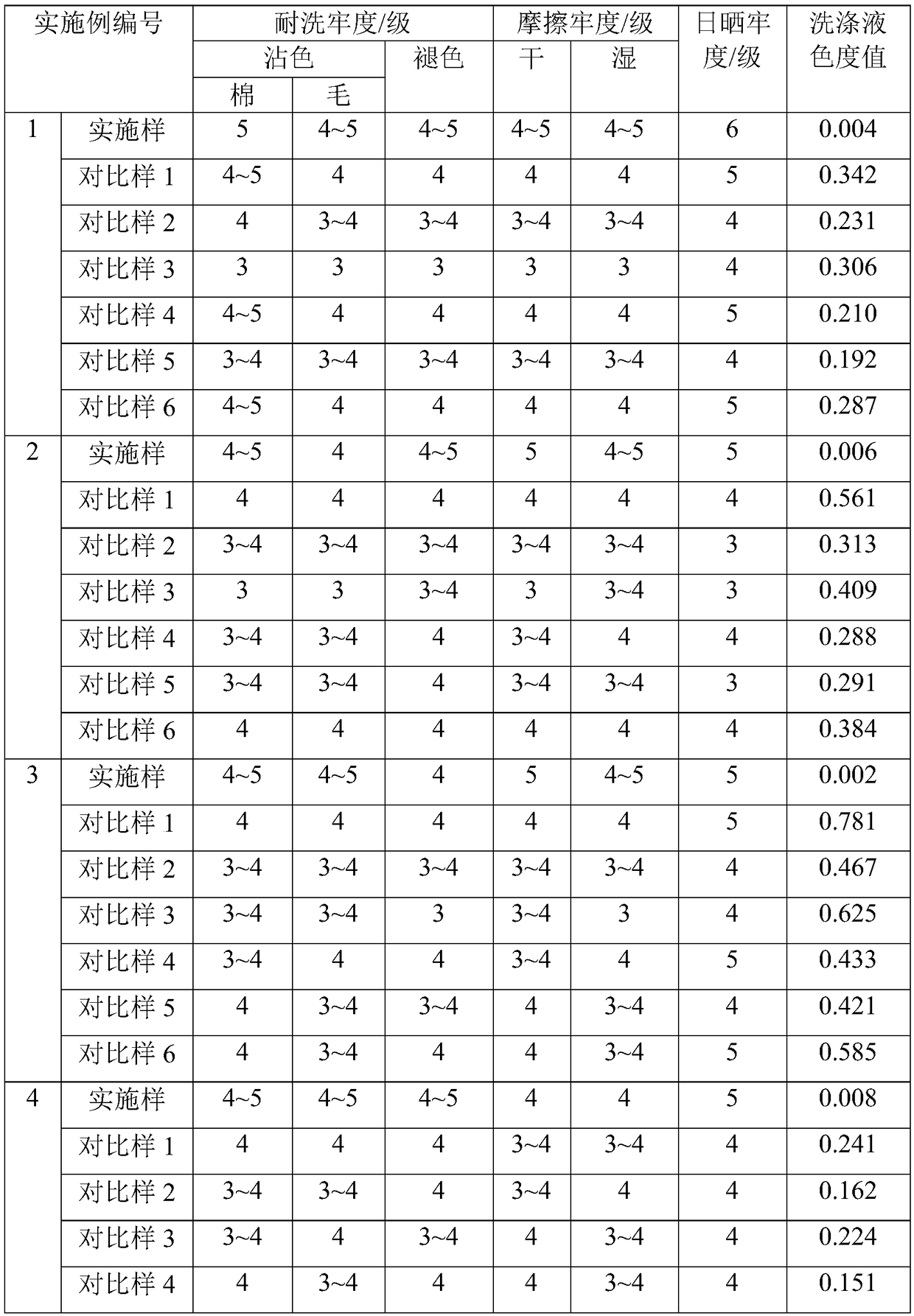

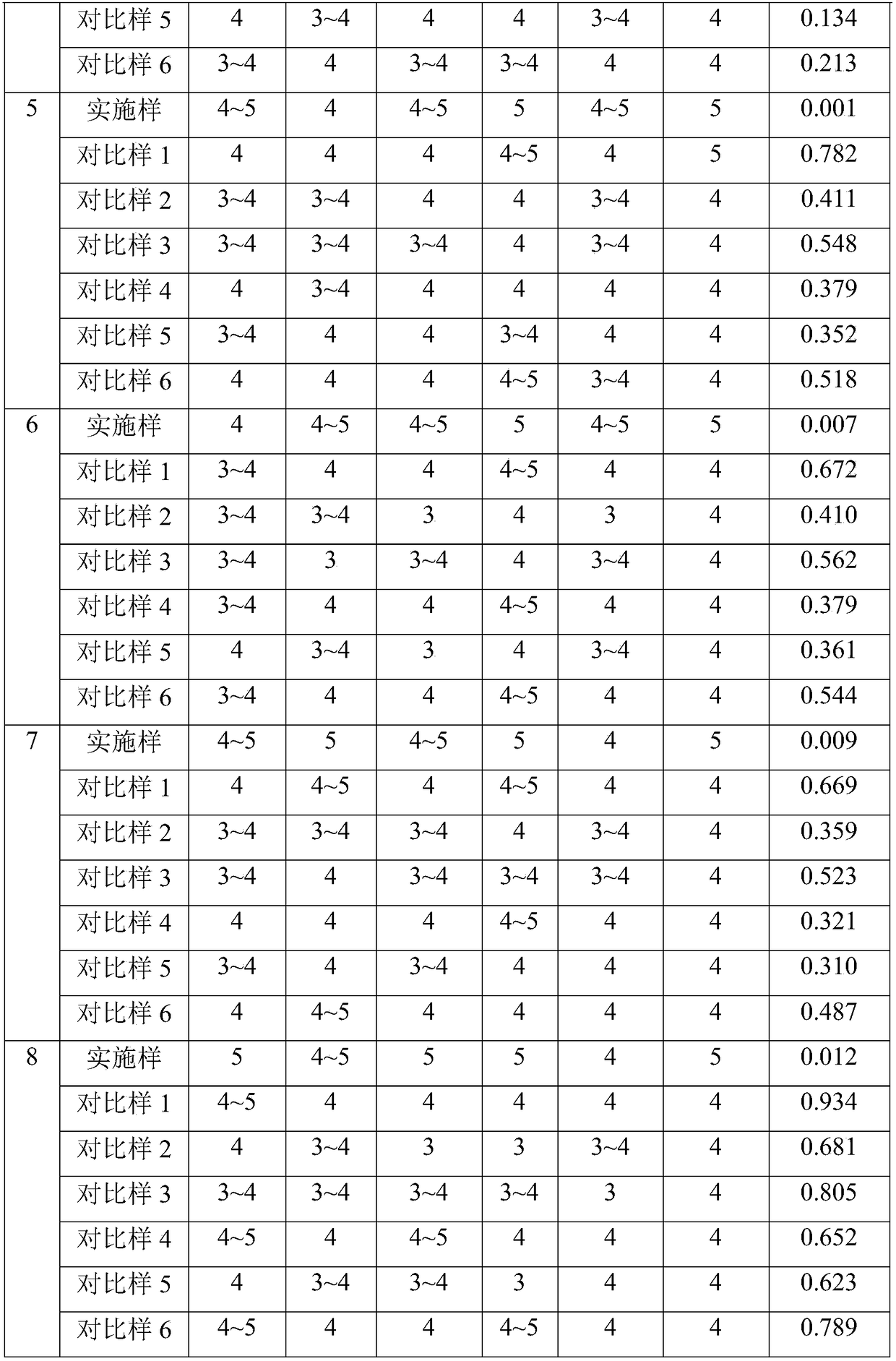

Instant accelerating agent for reactive dye and application method of instant accelerating agent

InactiveCN107190528AReduce the amount addedLow Inorganic Salt ContentDyeing processPotassiumPotassium carbonate

The invention belongs to the field of textile fabric dyeing, and particularly relates to an instant accelerating agent for a reactive dye and an application method of the instant accelerating agent. The instant accelerating agent comprises, by weight, 1-5 parts of sodium hydroxide, 2-3 parts of sodium carbonate, 0.5 part of polyvinylpyrrolidone, 1-5parts of potassium carbonate, 1-5 parts of sodium-2-naphthalene sulfonate, 1-5 parts of sodium gluconate, 4-8 parts of potassium sulphate, 25-40 parts of sodium chloride and 30-60 parts of sodium sulfate. Compared with the prior art, the instant accelerating agent and the application method have the advantages that a reasonable formula is utilized, so that the instant accelerating agent effectively replaces anhydrous sodium sulphate and sodium carbonate in use, the addition amount of inorganic salt is reduced and is 68-70% of the original usage amount, the product quality is improved, meanwhile, the production time is reduced, the cost is saved, the enterprise benefits are ensured, the content of the inorganic salt in dye-bath water is reduced, the number of times for after-treatment washing is reduced, the wastewater treatment degree is reduced, and the instant accelerating agent is suitable for large-scale application and popularization.

Owner:孙志君

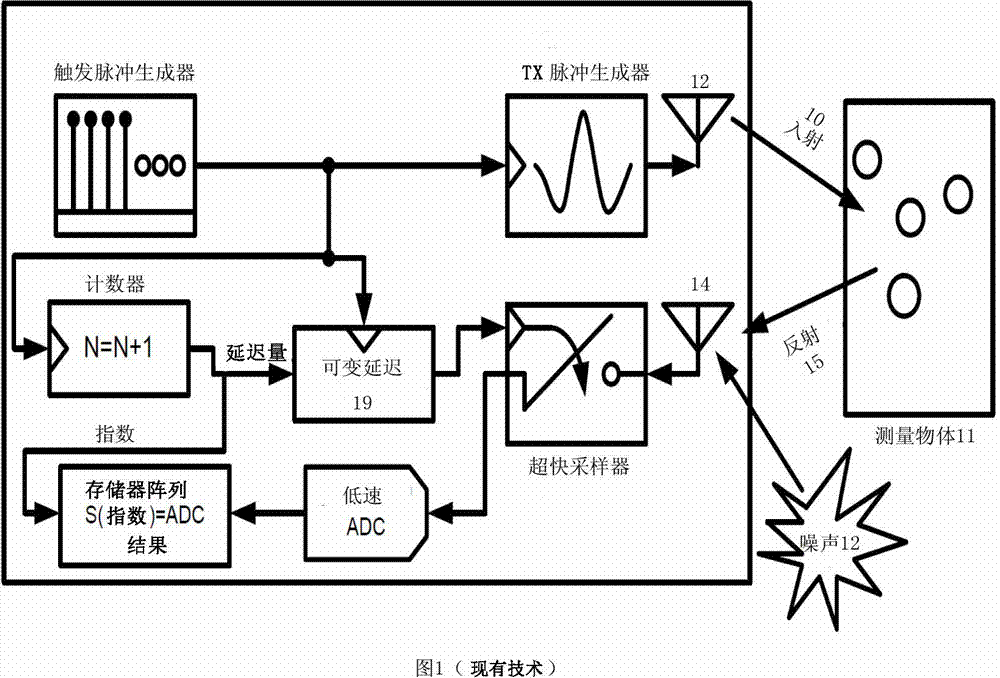

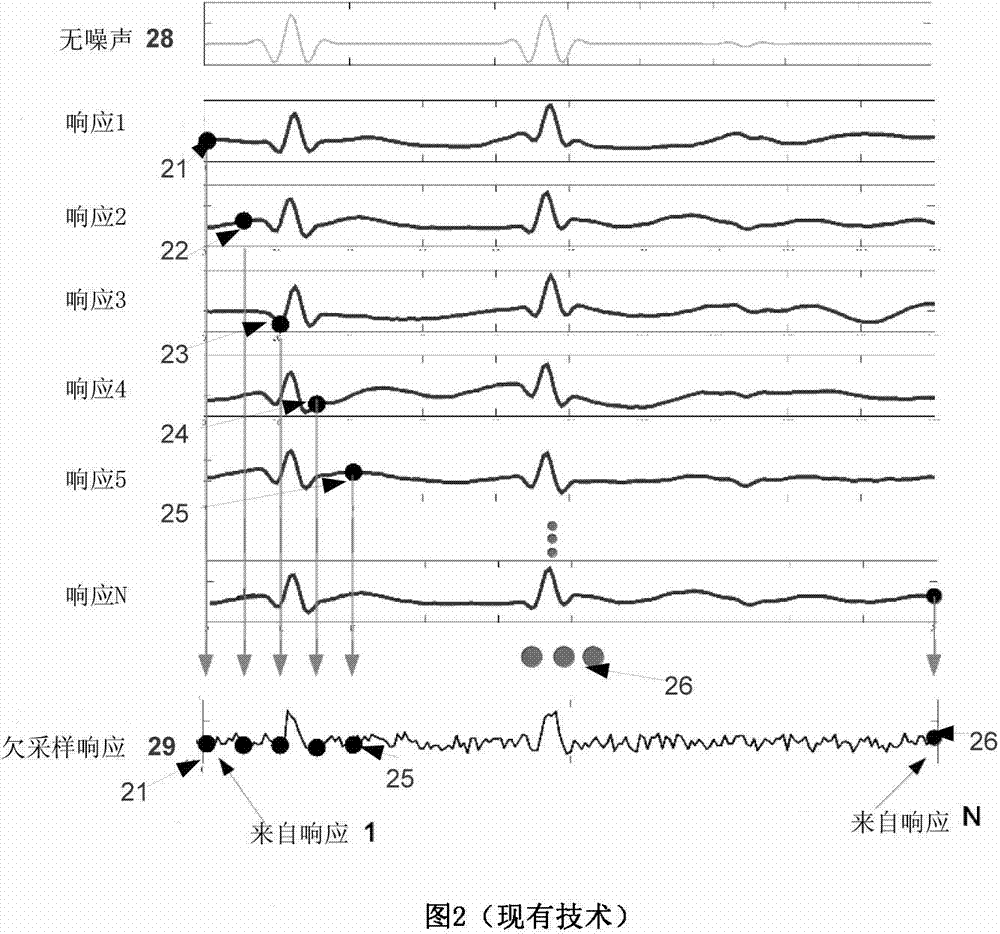

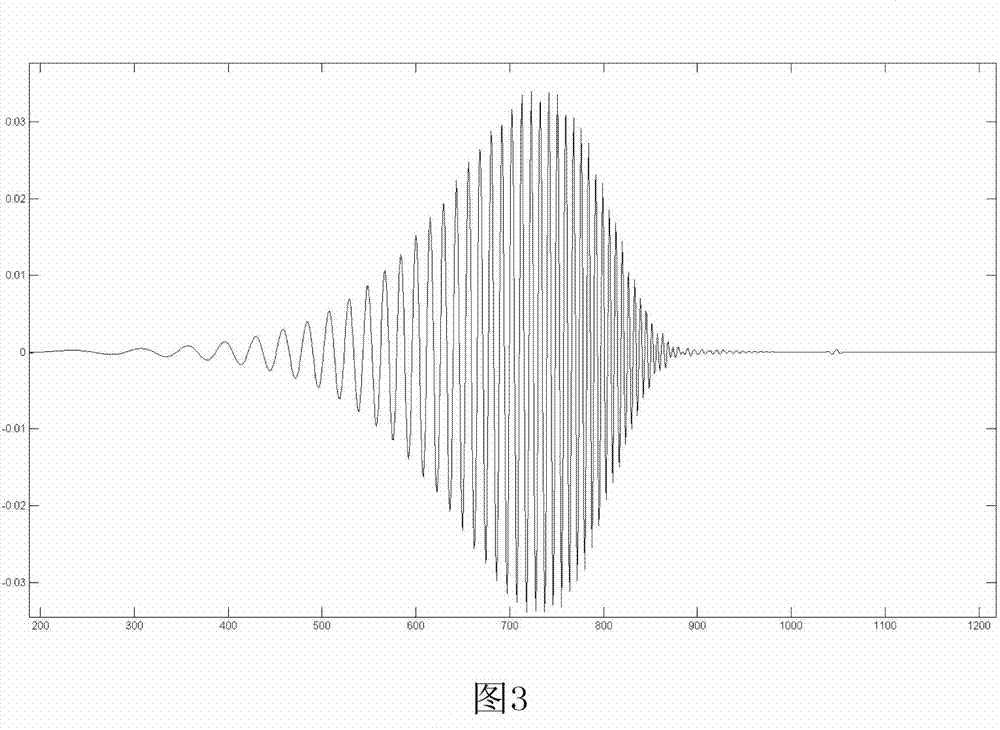

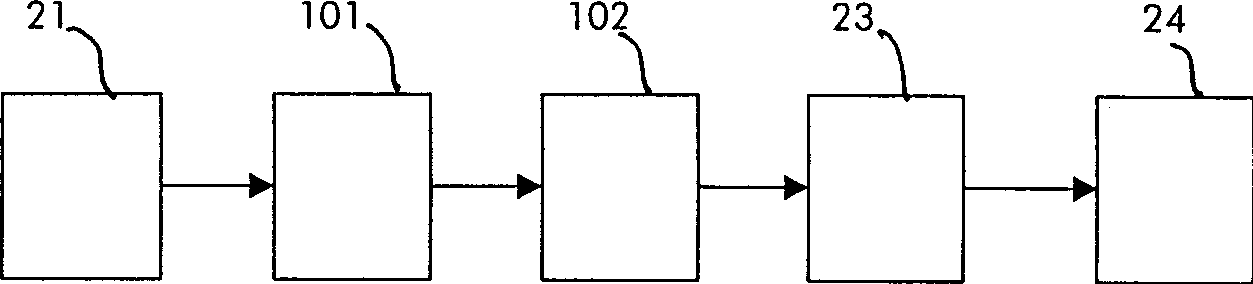

Realization of time-domain ultra wideband ground-penetrating radar using high speed accumulation and interpolated sampling

ActiveCN103592634AReduce processing powerExcellent GPR measurement resultsDetection using electromagnetic wavesRadio wave reradiation/reflectionUltra-widebandTime domain

Embodiments of the disclosed technology use high-speed interpolated (interdigitated) sampling for the specific purpose of GPR (Ground-Penetrating RADAR). This technology solves several issues associated with high-speed sampling in GPR which included 1) dynamic range limitations, 2) regulatory compliance issues, 3) sampler core offset error, and 4) timing errors. High-speed interpolated sampling GPR is implemented using a high-speed ADC in combination with trigger logic (such as an FPGA) and a programmable delay generator. The FPGA or other trigger logic generates a series of randomly dithered trigger pulses. A variable delay generator (or "Vernier") is synchronously controlled in order to produce the fractional timing. The timing of the pulses is randomly or pseudo-randomly dithered, and the phase of the interpolation is shuffled in order to avoid producing discrete spectral lines in the radiated RADAR signal.

Owner:GEOPHYSICAL SURVEY SYST

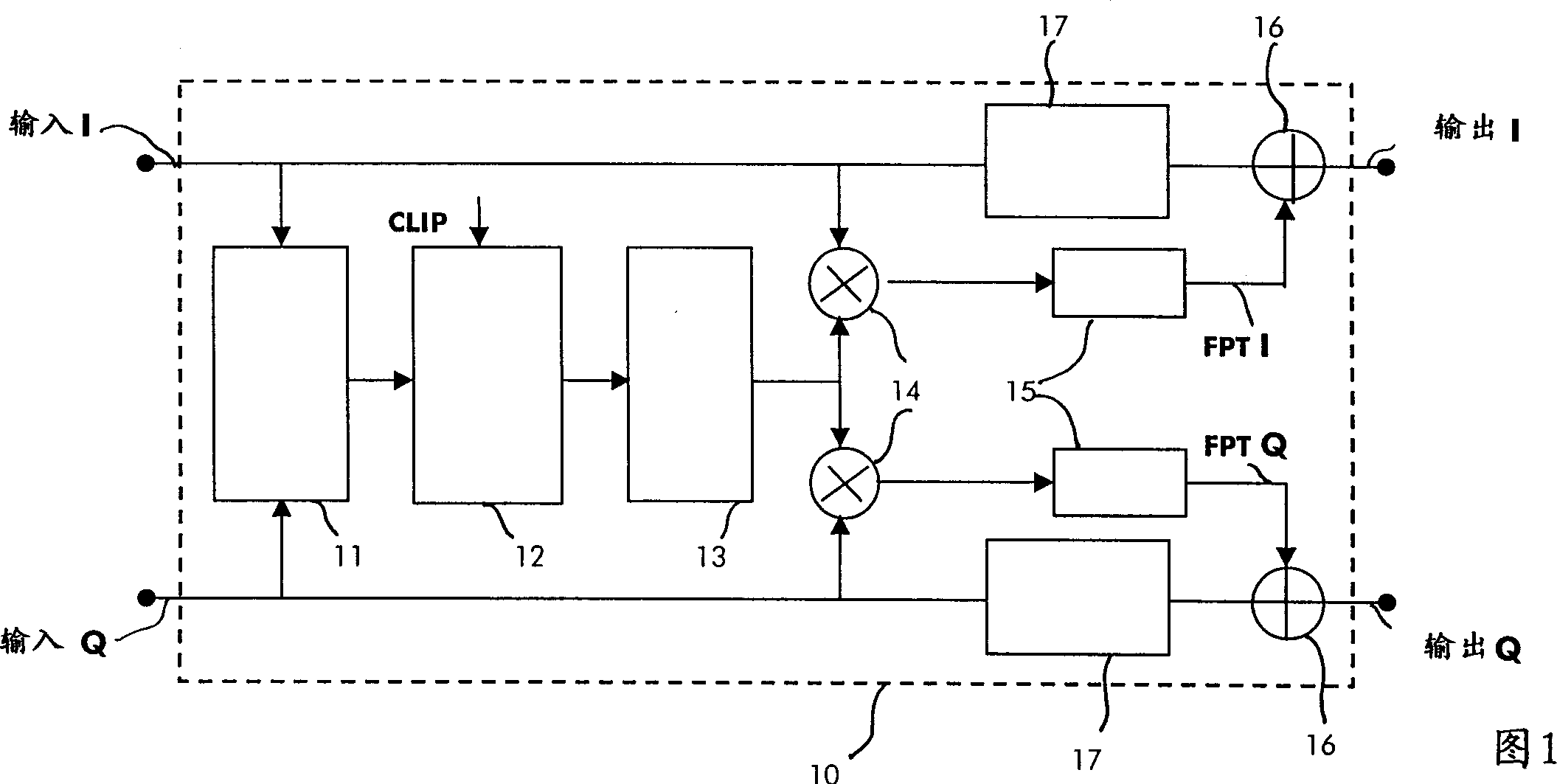

Method for amplitude-limited wide-band radio signal and relative transmitter

InactiveCN1359245ASmall distortionReduce processing powerAmplifier modifications to reduce non-linear distortionCode division multiplexElectric signalAmplifier

Owner:ALCATEL LUCENT SAS

A Method for Dynamically Controlling the Periodic Micro-Nano Structure of Crystalline Silicon Surface Based on Square Hole Assisted Electrons

ActiveCN104625416BLower ablation thresholdEfficient and precise designLaser beam welding apparatusMicro nanoNano structuring

The invention relates to a method for electronic dynamic control of crystal silicon surface periodic micro-nano structures based on square hole assistance and belongs to the technical field of femtosecond laser application. The method is based on local transient electronic excitation dynamic control, and femtosecond laser linear polarization is focused through an objective lens and then is focused on the surface of a material through a square hole copper wire mesh to achieve various precise control of different surface periodic micro-nano structures; by controlling laser scanning speed and pulse energy, ablation of strip-shaped surface corrugated structures and multi-point array micro-nano structures is achieved; by controlling the relative positions of the laser polarization direction and the direction (x axis) of the edge of a square hole, direction control of the periodic micro-nano structures can be achieved; by effectively adjusting the included angle between the linear polarization laser direction and the direction (x axis) of the edge of the square hole, selective ablation of the crystal silicon surface periodic micro-nano structures is achieved. Compared with existing methods, the method has the advantages that surface processing precision and efficiency are improved effectively, and efficient and accurate form control of the surface periodic micro-nano structures is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Breeding wastewater treatment apparatus

InactiveCN106064870AReduce processing powerReduce processing costsTreatment using aerobic processesSpecific water treatment objectivesGratingAnaerobic reactor

The invention discloses a breeding wastewater treatment apparatus comprising, in a successively connected manner, a primary filtering tank, a solid liquid separator, an anaerobic reactor, an anoxic tank, an aerobic tank, a precipitation tank, a water culturing tank, and also a biogas tank and a sludge tank, wherein the biogas tank is connected to the anaerobic reactor; the primary filtering tank, the solid liquid separator, the anaerobic reactor and the precipitation tank are all connected to the sludge tank; a grating is arranged in the primary filtering tank; and an aeration pipe is arranged in the water culturing tank. The breeding wastewater treatment apparatus is low in energy consumption and is high in utilization rate on organic substances in the wastewater.

Owner:广西宏业环保节能工程有限公司

Secure real-time data transmission

ActiveCN109104401ANegligible additional costReduce power lossProgramme controlUser identity/authority verificationTime dataTransmitter

A method for real-time-based transfer of data telegrams from a verified transmitter to a verified receiver without delays, wherein (a) each data telegram to be transferred from the transmitter to thereceiver is provided with an additional data index, (b) each received data is stored in a memory, along with the associated additional data index, (c) after elapse of a predetermined time interval, orafter transference of a defined number of data telegrams, the transmitter transfers a second time data telegram already transferred to the receiver which has an additional signature, and where the data telegram transferred the second time is additionally encrypted by the transmitter, and (d) after receiving the signed data telegram transferred the second time, the signed data telegram transferredthe second time is compared with the corresponding data telegram stored in the memory to verify the transmitter, and where (e) steps a) to d) are repeated.

Owner:SIEMENS AG

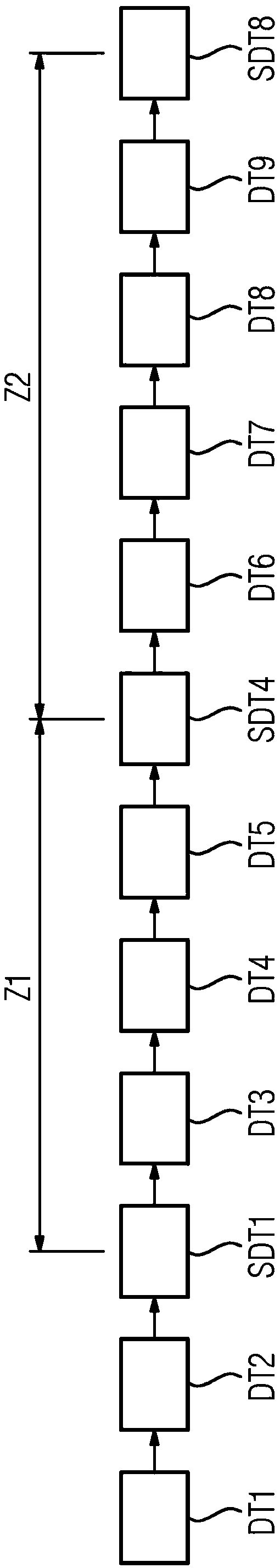

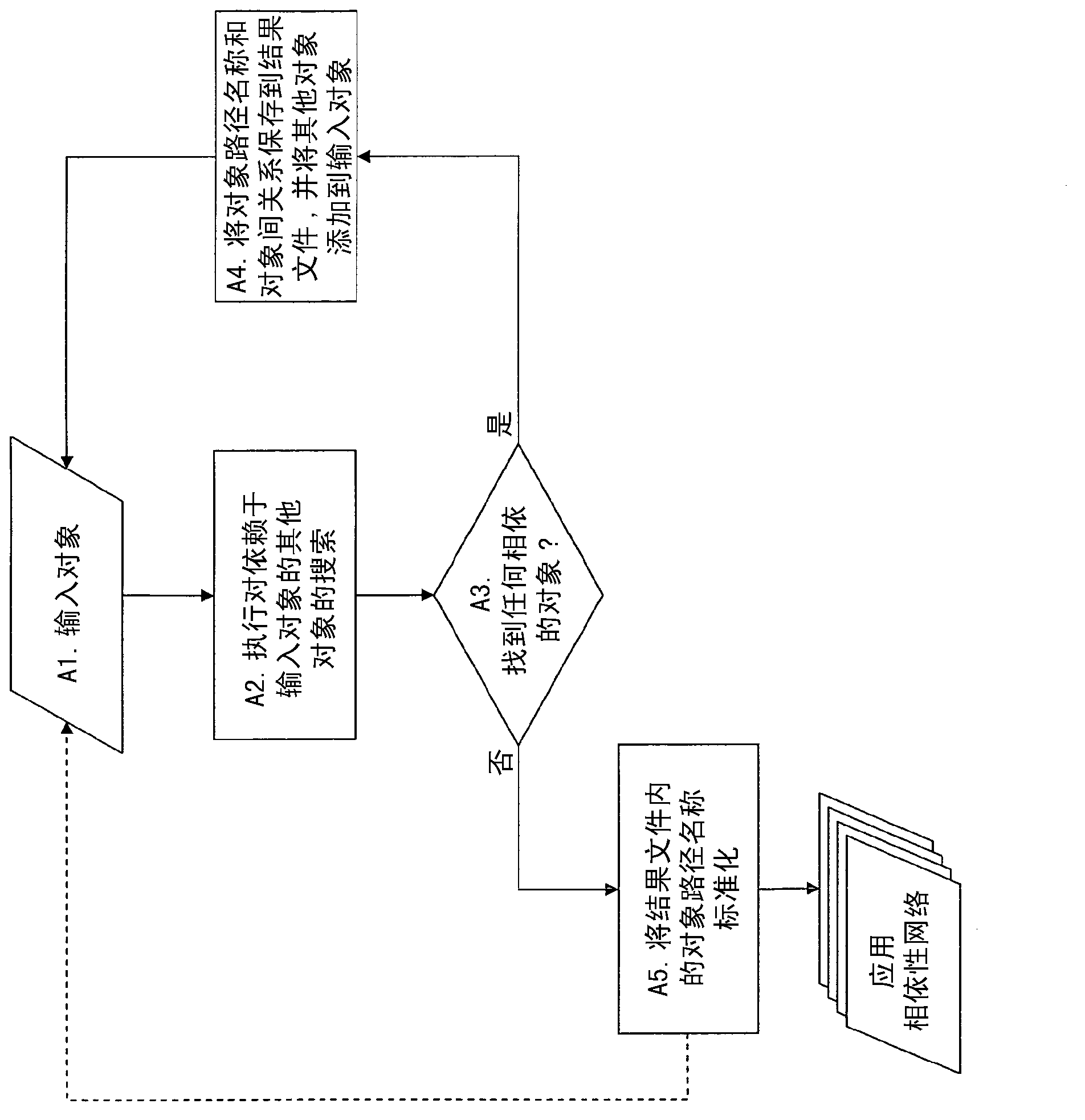

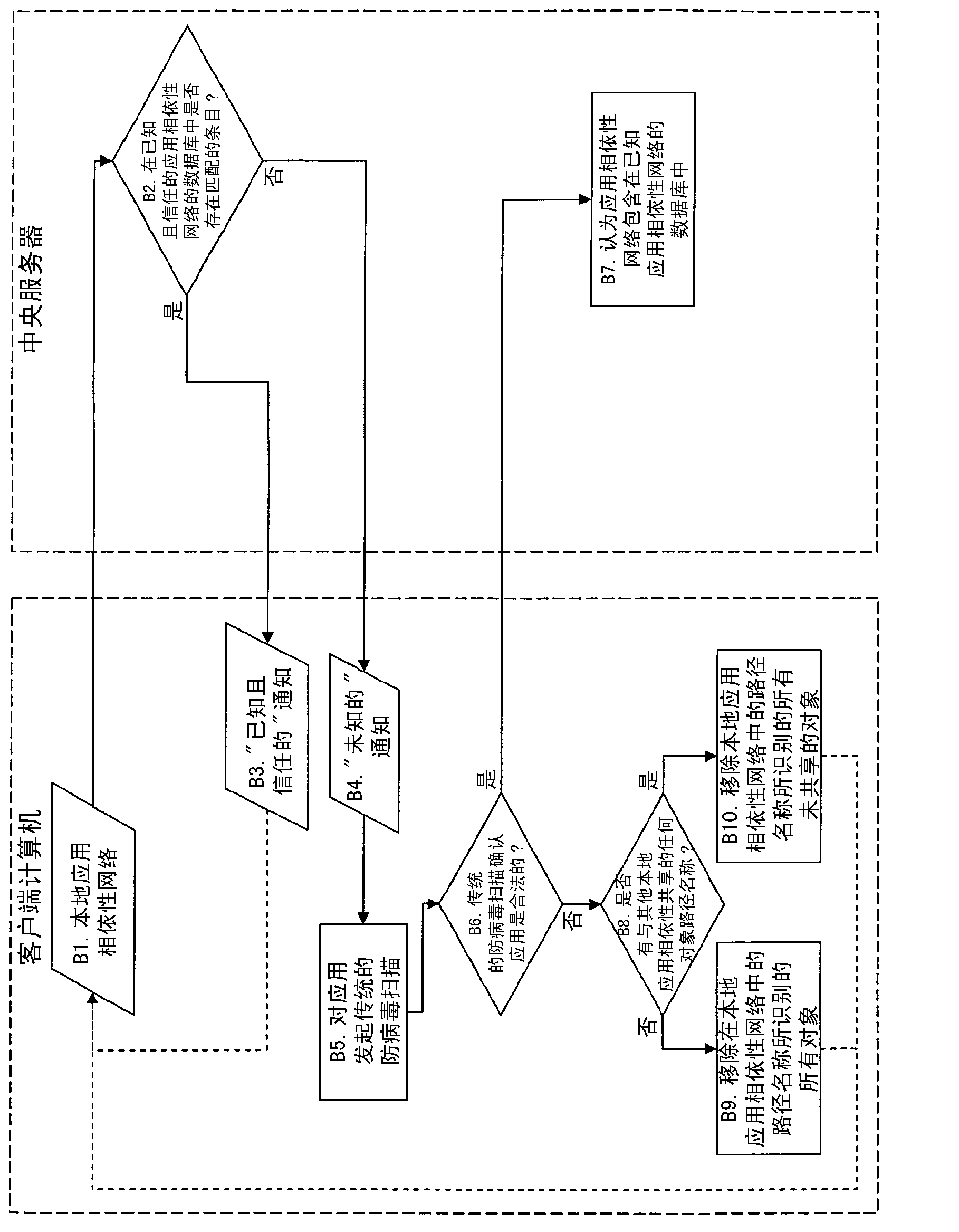

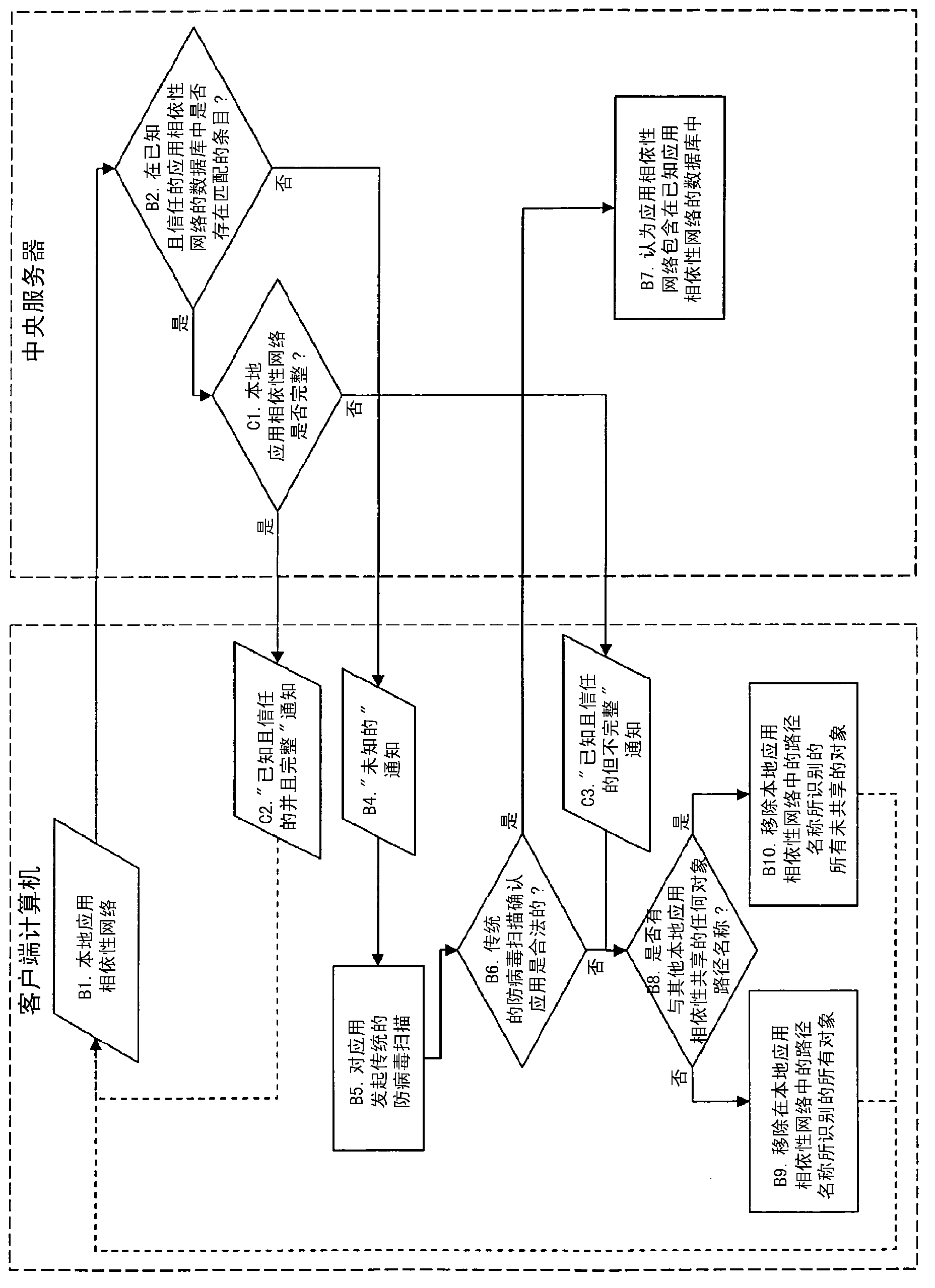

Computer system analysis method and apparatus

ActiveCN103180863AMake sure to deleteReduce processing powerPlatform integrity maintainanceSystems analysisComputerized system

A method of analysing a computer on which are installed a plurality of applications each comprising a set of inter-related objects. The method first comprises identifying a local dependency network for each of one or more of said applications, a local dependency network comprising at least a set of object paths and inter-object relationships. The (or each) local application dependency network is then compared against a database of known application dependency networks to determine whether the application associated with the local dependency network is known. The results of the comparison are then used to identify malware and / or orphan objects.

Owner:WITHSECURE CORP (A K A WITHSECURE OYJ)

Pipeline thread rolling and processing method and roll machine

InactiveCN1544178AReasonable structureHigh precisionScrew-threads articlesControl engineeringElectric machinery

The invention is a pipeline thread rolling method and the roller, nipping the pipeline on the pipe nipping mechanism driven by the electric machine, there is a thread rolling mechanism placed in the working front, there are rolling wheels in the rolling mechanism, the pipeline rotates and enters in between three rolling wheels coaxially and distributed at 120 deg. central angle in the thread rolling mechanism, rolling into a thread shape, the pipeline thread roller is composed of base, electric machine, reducer, guide pile locating mechanism and workpiece clamping mechanism, there is a sliding frame on the two guide piles and the there is a thread rolling mechanism set on the sliding frame, compared with existing techniques, it has the characters of reasonable structure, smooth thread, high precision, etc.

Owner:崔莹莹

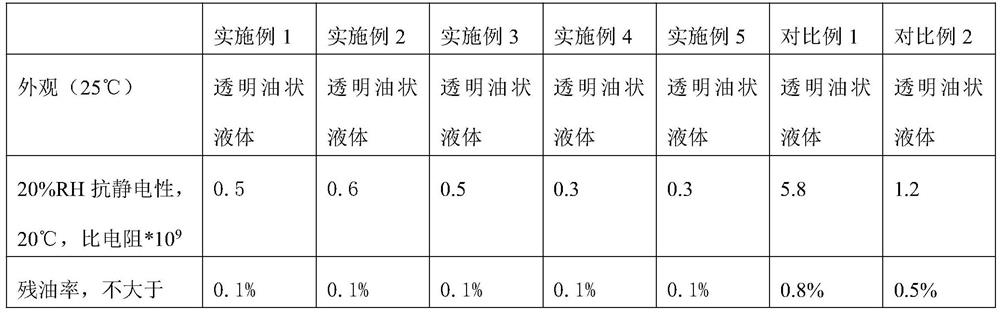

Environment-friendly water-based DTY oiling agent as well as application and application method thereof

PendingCN113832573AWide variety of sourcesEasy to processSynthetic polymer filament chemical after-treatmentVegetable oilSurface-active agents

The invention discloses an environment-friendly water-based DTY oiling agent as well as application and an application method thereof. The environment-friendly water-based DTY oiling agent is prepared from the following raw materials in parts by weight: 10 to 15 parts of vegetable fat and oil, 10 to 20 parts of alcohol ether, 4 to 9 parts of a surfactant and 65 to 80 parts of water. According to the DTY oiling agent provided by the invention, the vegetable fat and oil, the alcohol ether, the surfactant and the water are adopted as main components, and the DTY oiling agent is water-based liquid in appearance and free of oil droplets; and the raw materials are wide in source and degradable, biolipid raw materials are adopted, mineral oil is not used as a lubricant, environmental protection is achieved, and during use, the raw materials can be fully matched with the DTY, so that the DTY is convenient to process, the working efficiency of textile users and the product grade are improved, the emission of weaving and printing and dyeing enterprises is changed, the water treatment cost and the strength of the enterprises are reduced, and the emission requirement is met.

Owner:苏州市吴江区顺源植物油脂科技有限公司

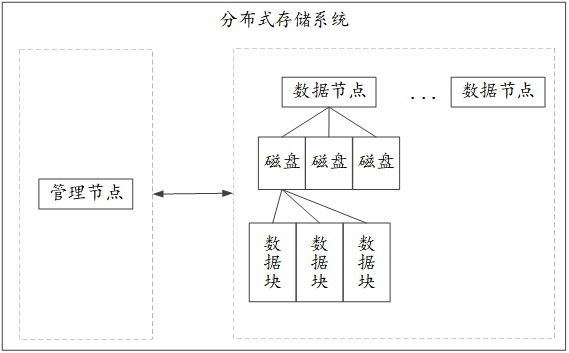

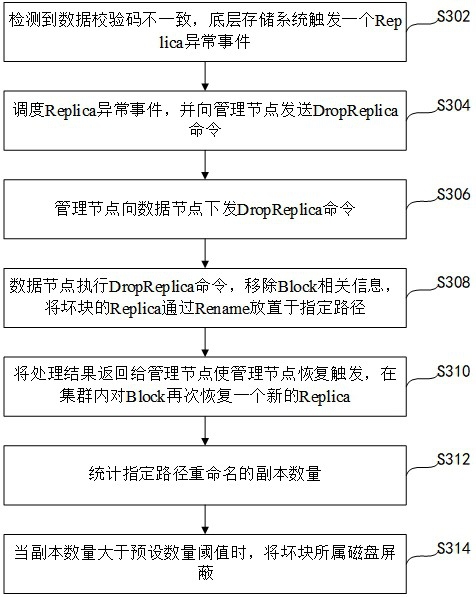

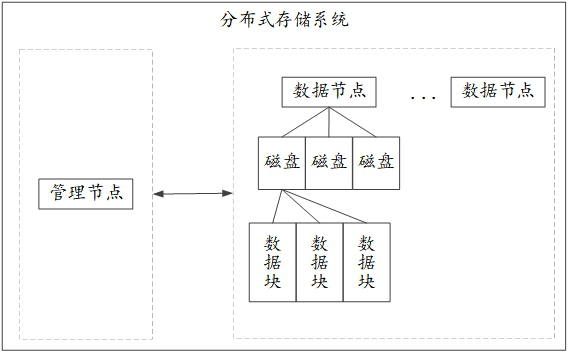

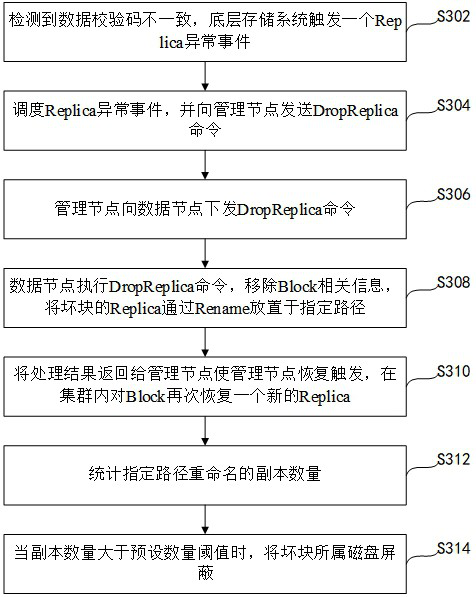

Distributed storage system disk failure processing method, device and server

ActiveCN114415970BReduce processing powerSmall area of influenceInput/output to record carriersNon-redundant fault processingData nodeEmbedded system

Owner:BEIJING KINGSOFT CLOUD NETWORK TECH CO LTD

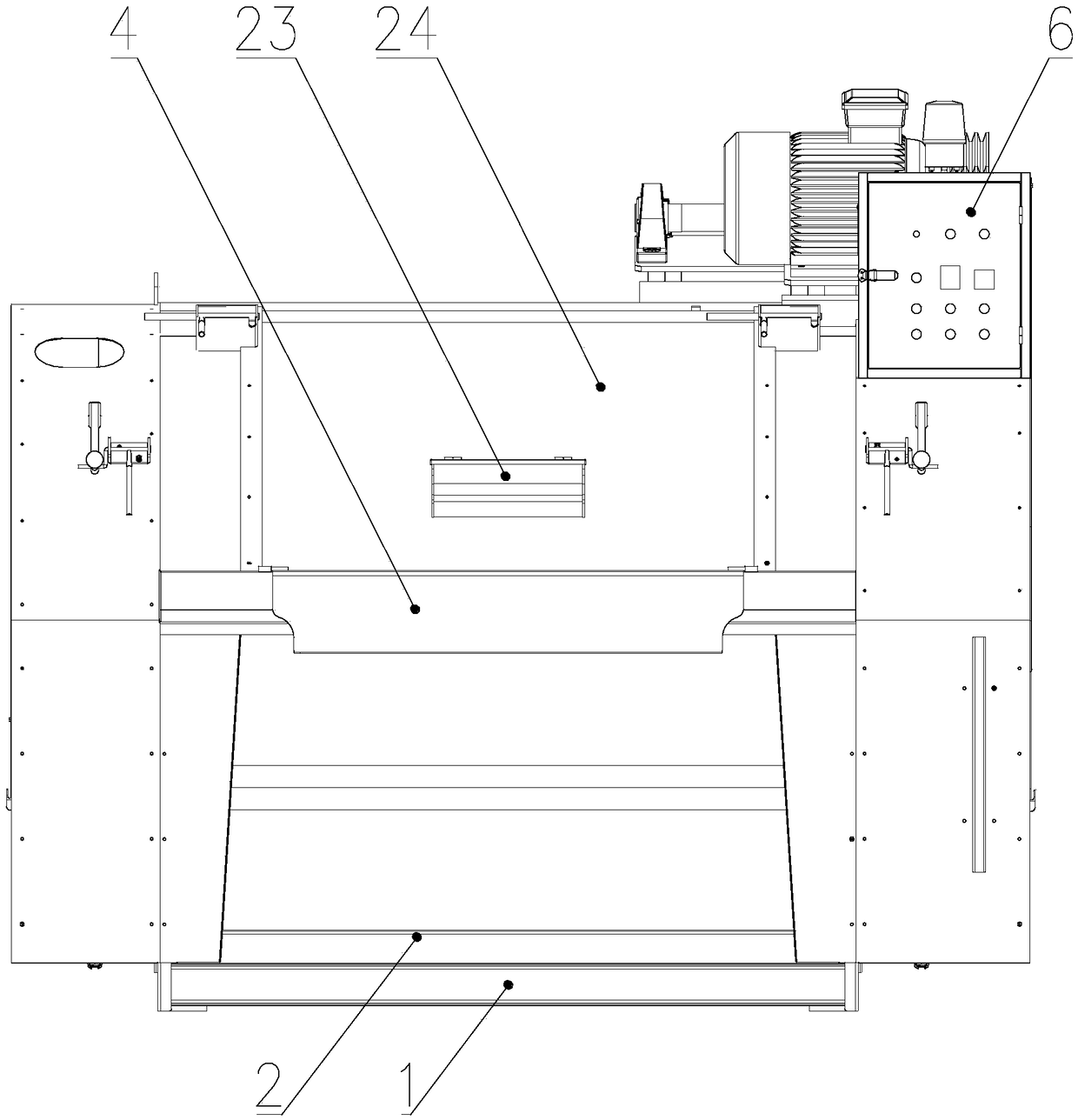

Washing method of trace-atomizing washing machine and washing machine using method

ActiveCN109881407AReduce water consumptionReduce processing powerTextile treatment machine arrangementsLiquid/gas/vapor removal by centrifugal forceSpray nozzlePulp and paper industry

The invention relates to the field of industrial washing machines, and provides a washing method of a trace-atomizing washing machine and the washing machine using the method in order to overcome thedefects in the prior art. The washing machine comprises an outer tub and an inner tub which are fixed to a machine base, and a rotating shaft driven by a motor. The inner tub is coaxially and horizontally arranged in the outer tub and driven by the rotating shaft to rotate. A tub door is formed in the tub mouths of the inner tub and the outer tub and provided with spraying nozzles facing the interior of the tubs. The invention further provides the washing method of the washing machine. The method includes a first process and a second process. Compared with the prior art, the water consumptionof the washing machine is greatly reduced, the subsequent sewage treatment intensity is reduced, the pollution of a detergent to the environment is reduced, and the production cost is reduced. The work intensity of carrying workers of a factory is reduced. Mixed liquid of tap water and the detergent is secondarily utilized, and the utilization rate of the detergent is increased. Compared with a traditional soaking type washing method, the clothes cross dyeing risks are reduced.

Owner:广州市信宏洗衣机械有限公司

Devices and methods for processing touch inputs based on adjusted input parameters

ActiveCN109416599AReduce usageExtension of timeInput/output processes for data processingSurface displaySimulation

An electronic device with a display, a touch-sensitive surface, and one or more sensors to detect intensity of contacts with the touch-sensitive surface displays a first user interface of a first software application, detects an input on the touch-sensitive surface while displaying the first user interface, and, in response to detecting the input while displaying the first user interface, performsa first operation in accordance with a determination that the input satisfies intensity input criteria including that the input satisfies an intensity threshold during a first predefined time period,and performs a second operation in accordance with a determination that the input satisfies long press criteria including that the input remains below the intensity threshold during the first predefined time period.

Owner:APPLE INC

A washing method of a micro atomization washing machine and a washing machine adopting the method

ActiveCN109881407BReduce water consumptionReduce processing powerTextile treatment machine arrangementsLiquid/gas/vapor removal by centrifugal forceLaundry washing machineWash water

The present invention relates to the field of industrial washing machines, and aims to overcome the deficiencies of the prior art, and provide a washing method for a micro atomization washing machine and a washing machine using the method, including an outer barrel, an inner barrel and an A rotating shaft driven by a motor; the inner barrel is coaxially arranged in the outer barrel and rotated by the drive of the rotating shaft; a barrel door is provided at the mouth of the inner barrel and the outer barrel, and the barrel door is provided with a nozzle. The present invention also includes the water washing method of the washing machine, including the first process and the second process. Compared with the prior art, the water consumption of the washing machine is greatly reduced, thereby reducing the intensity of subsequent sewage treatment, reducing the environmental pollution caused by detergents, and reducing production costs. The work intensity of the factory porters is reduced. The mixed solution of tap water and detergent is reused, which improves the utilization rate of detergent. Compared with the traditional soaking washing method, the invention reduces the risk of cross-staining of clothes.

Owner:广州市信宏洗衣机械有限公司

Device and method for processing touch input

ActiveCN109416599BImprove satisfactionReduce usageInput/output processes for data processingComputer hardwareDisplay device

The present invention provides an electronic device having a display, a touch-sensitive surface, and one or more sensors for detecting the intensity of contact with the touch-sensitive surface, the electronic device displaying a first user of a first software application an interface that detects an input on the touch-sensitive surface while the first user interface is being displayed, and in response to detecting the input while the first user interface is being displayed, during a first predefined time period according to the determination The input satisfies an intensity input criterion comprising the input meeting an intensity threshold, a first operation is performed, and according to the determination the input satisfies including the input remains below the intensity threshold during the first predefined period of time The long press standard to perform the second operation.

Owner:APPLE INC

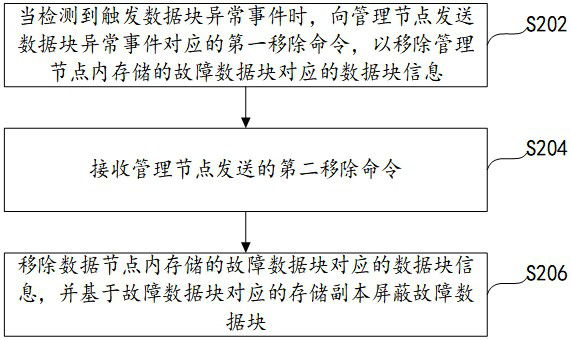

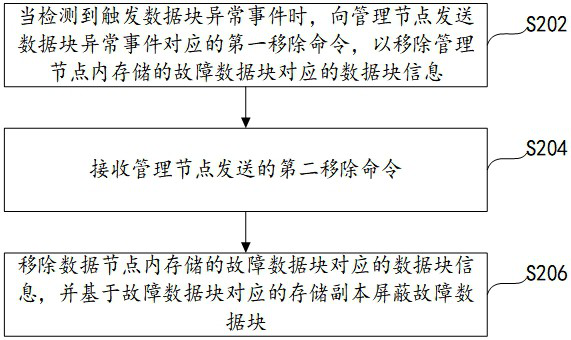

Disk fault processing method and device of distributed storage system and server

ActiveCN114415970AReduce processing powerSmall area of influenceInput/output to record carriersNon-redundant fault processingData balancingData node

The invention provides a disk fault processing method and device of a distributed storage system and a server, and relates to the technical field of computers, and the method comprises the following steps: when a data block exception triggering event is detected, sending a first removal command corresponding to the data block exception event to a management node, data block information corresponding to the fault data block stored in the management node is removed; receiving a second removal command sent by the management node; and removing data block information corresponding to the fault data block stored in the data node, and shielding the fault data block based on the storage copy corresponding to the fault data block. According to the method, the influence range of data block faults can be remarkably reduced, the processing strength of disk faults is reduced, and the frequency of data recovery operation and data balancing operation is effectively reduced.

Owner:BEIJING KINGSOFT CLOUD NETWORK TECH CO LTD

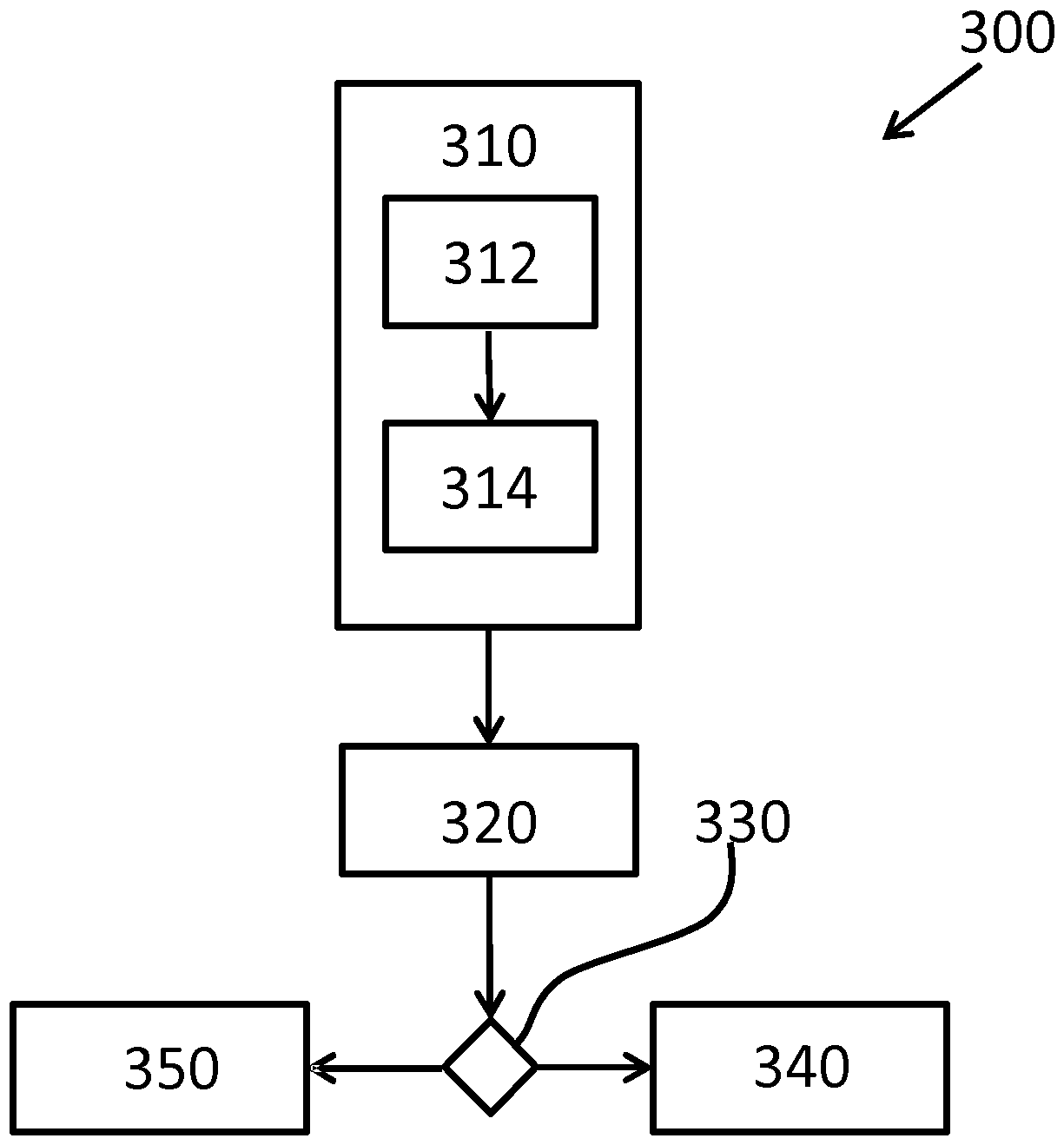

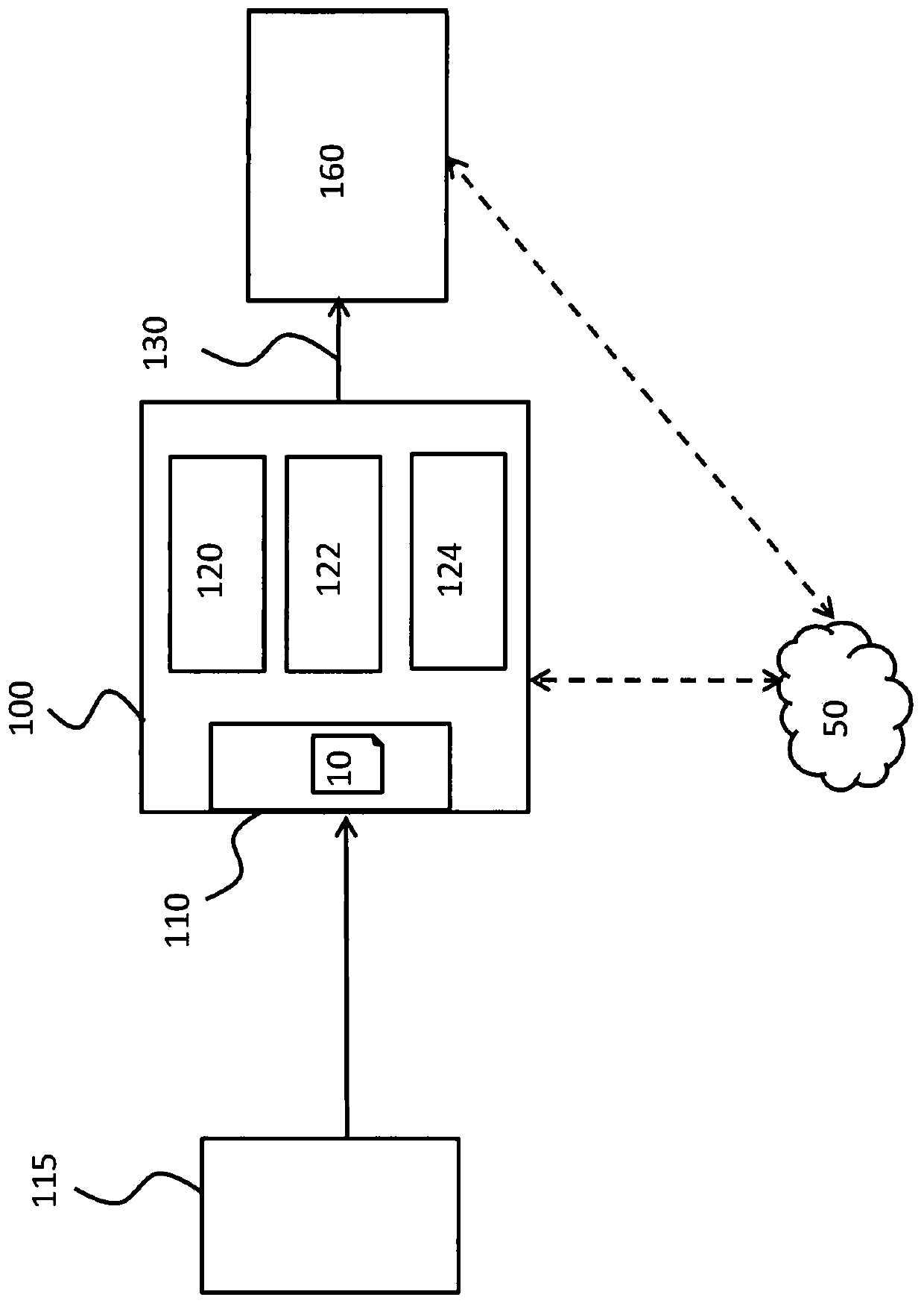

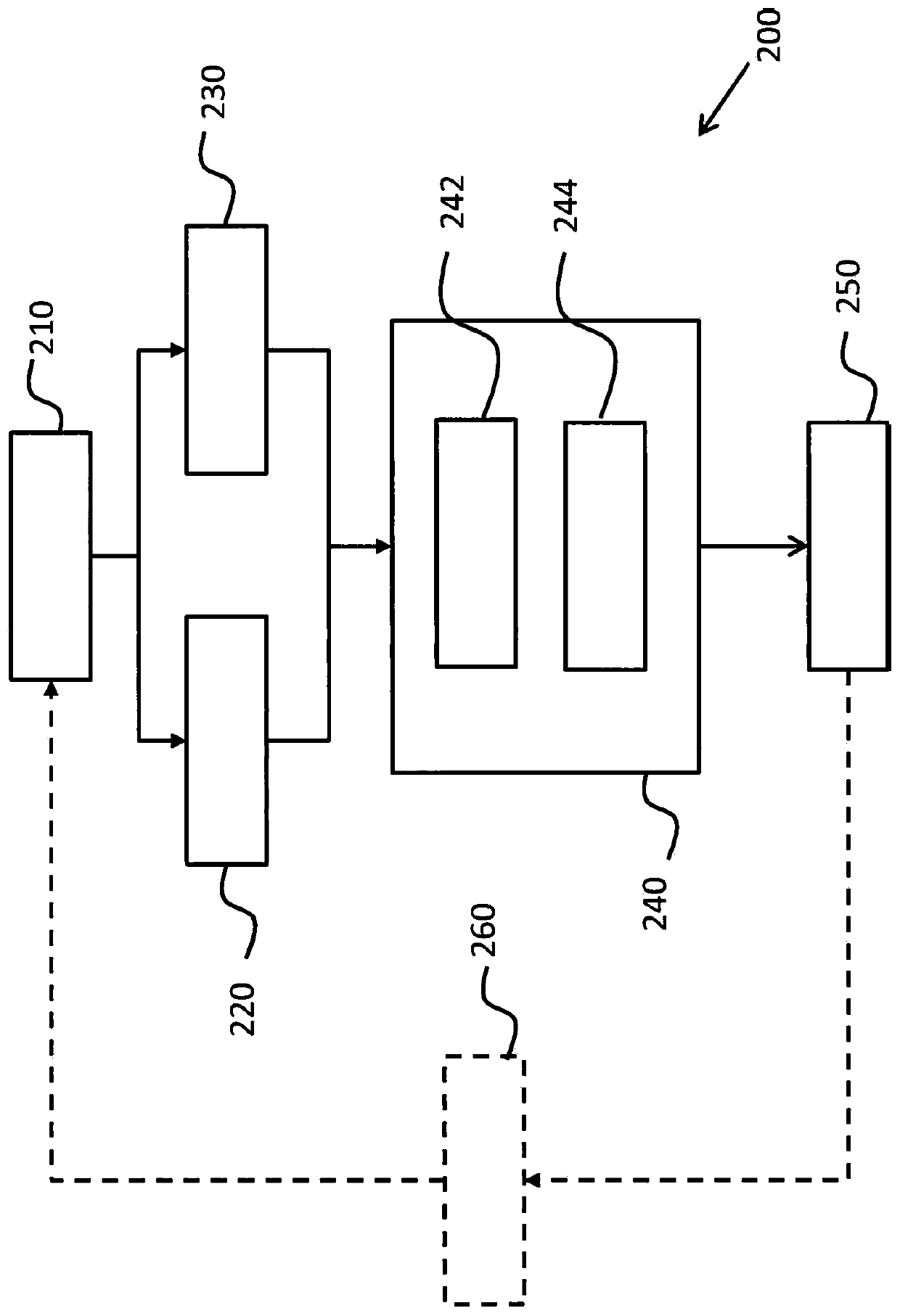

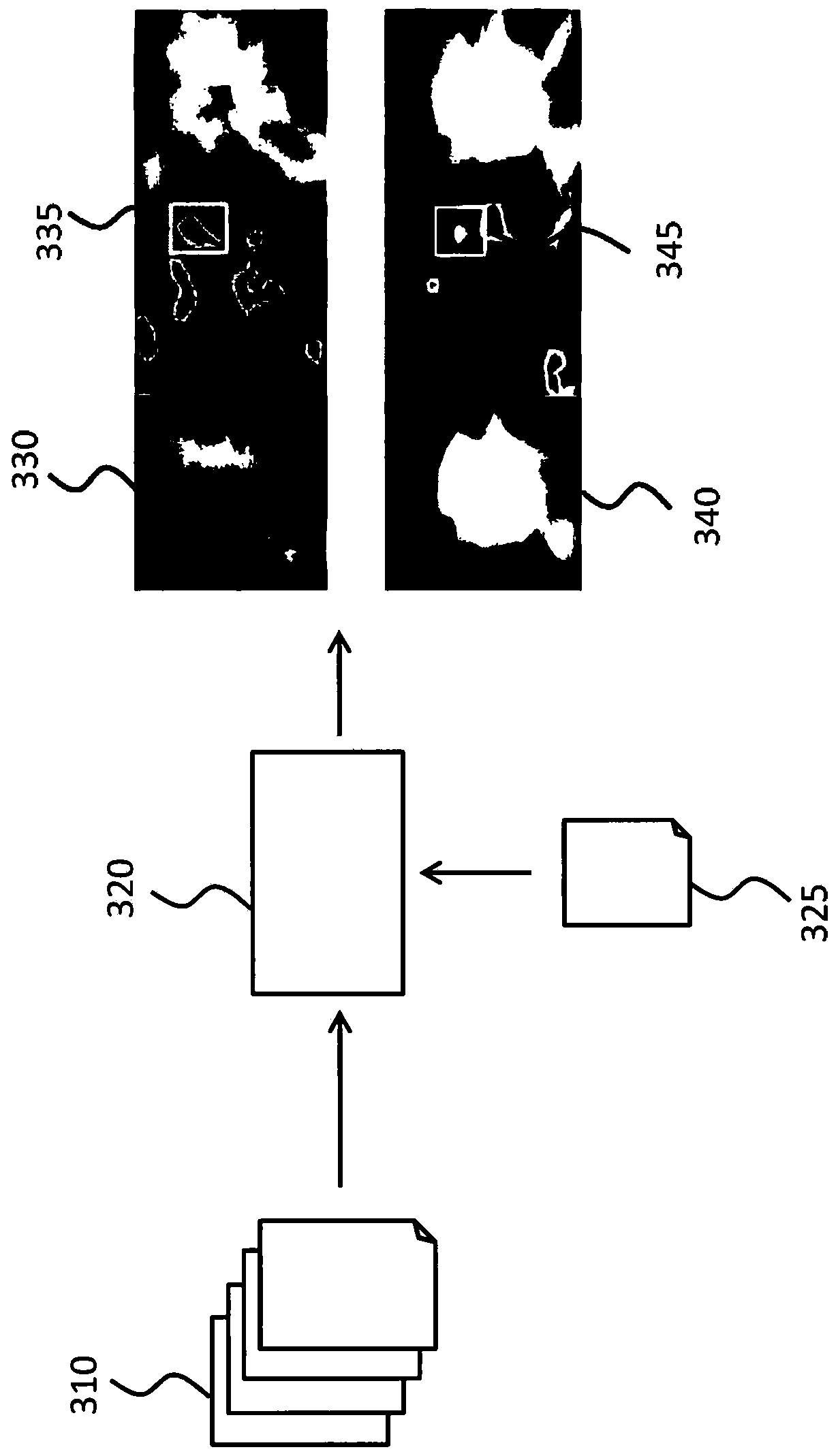

Feature identification in medical imaging

PendingCN111243711ARapid assessmentQuick verificationImage enhancementImage analysisGenerative adversarial networkMedical imaging

Presented are concepts for feature identification in medical imaging of a subject. One such concept processes a medical image with a Bayesian deep learning network to determine a first image feature of interest and an associated uncertainty value, the first image feature being located in a first sub-region of the image. It also processes the medical image with a generative adversarial network to determine a second image feature of interest within the first sub-region of the image and an associated uncertainty value. Based on the first and second image features and their associated uncertaintyvalues, the first sub-region of the image is classified.

Owner:KONINKLJIJKE PHILIPS NV

A kind of preparation method of highly gelling sterilized egg yolk liquid

ActiveCN111480804BReduce processImprove gelationFood denaturationFood ultrasonic treatmentBiotechnologyYolk

A method for preparing a highly gelatinized sterilized egg yolk liquid, the specific steps comprising: (1) removing the egg white part after fresh eggs are pretreated to obtain egg yolk liquid; (2) adjusting the pH of the egg yolk liquid for later use; (3) A highly gelatinized sterilized egg yolk liquid can be obtained by treating the spare egg yolk liquid with ultrasound-assisted ozone. The invention has the characteristics of ingenious technology, simple operation, short processing time, large processing capacity, environmental protection, low cost, and obvious modification effect. The ultrasonic-assisted ozone processing method can significantly improve the gel performance of egg yolk liquid, and save The sterilization link in the egg yolk processing process can improve the gelatinity and have a bactericidal effect, and it is a kind of cold sterilization that does not cause damage to the raw material of the egg yolk liquid. This preparation method can bring new ideas to the egg yolk liquid processing industry, and the processing method integrating modification and sterilization can greatly reduce costs and improve efficiency.

Owner:HUAZHONG AGRI UNIV

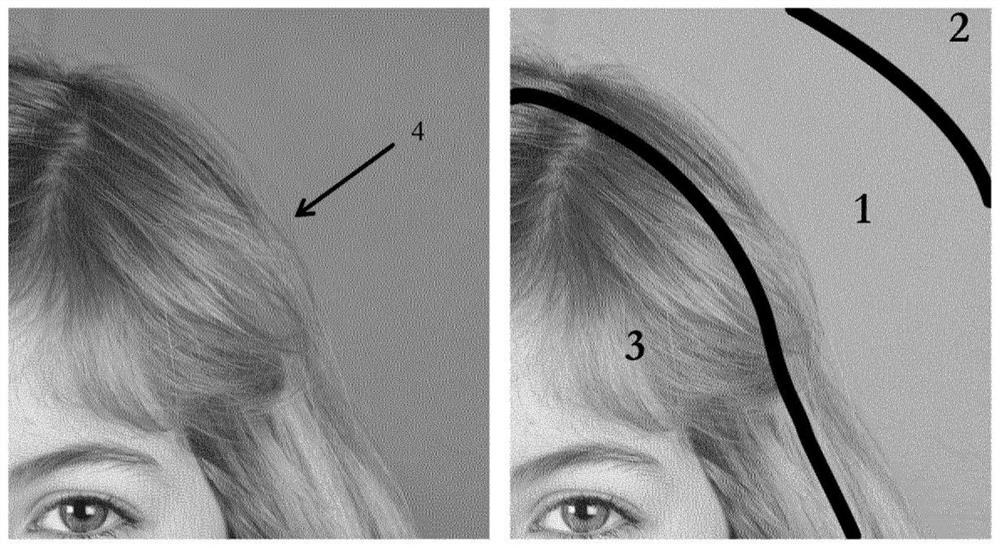

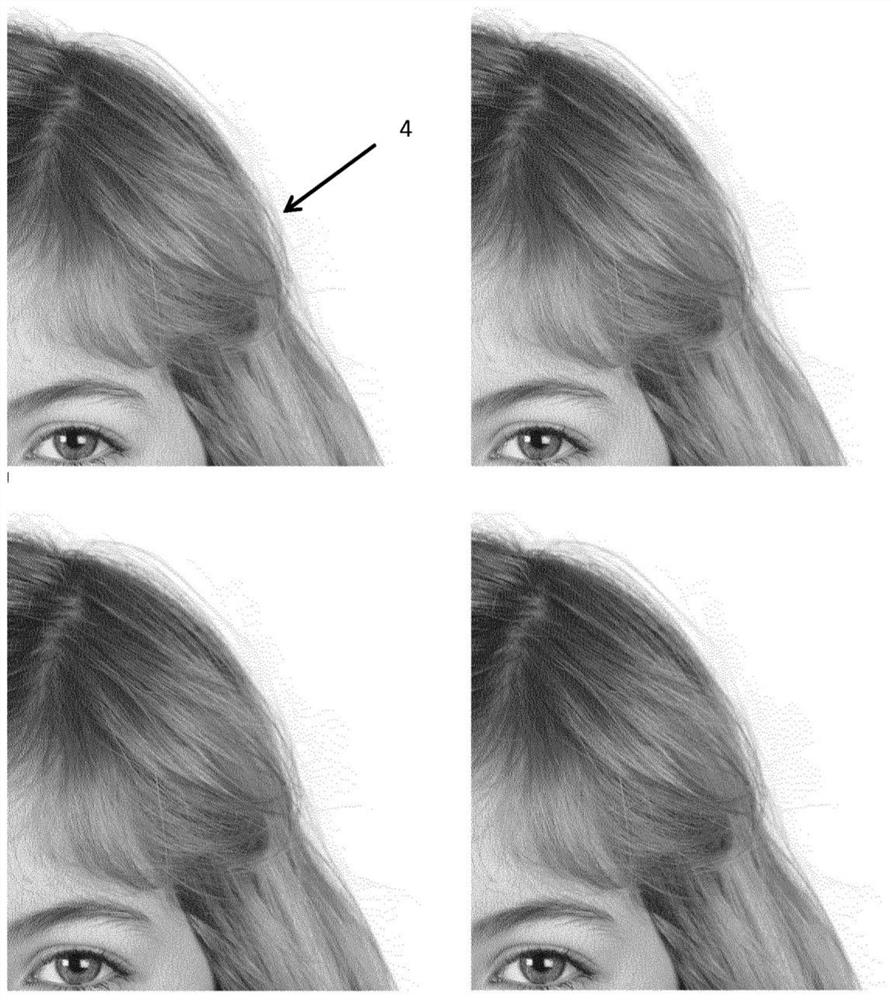

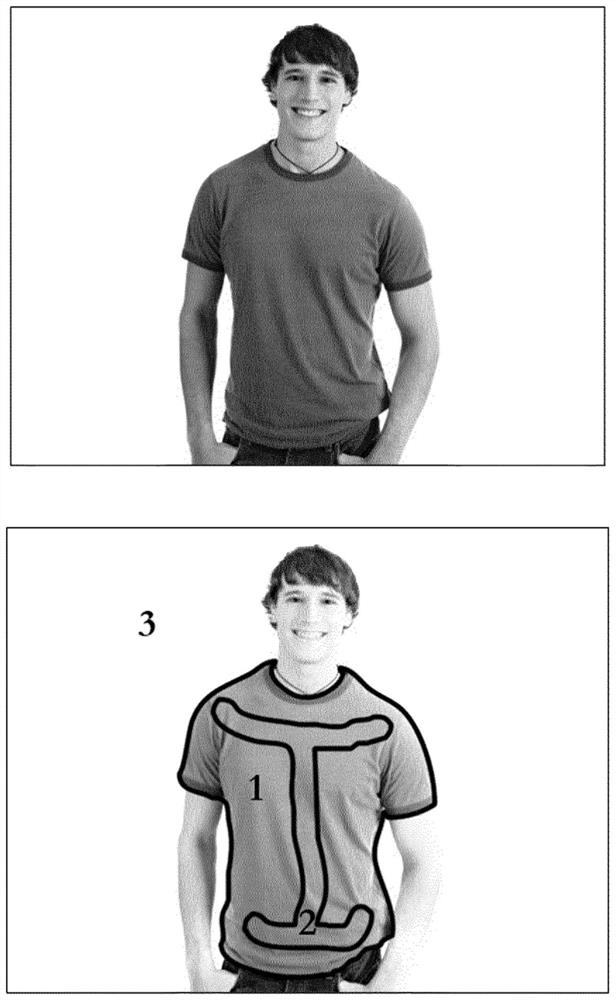

Method and device for correcting images

ActiveCN108352055BRemove color overflowHigh quality cutImage enhancementImage analysisPattern recognitionComputer graphics (images)

The invention discloses a device comprising a processing device and a method for color correction of an image in the processing device, the method comprising: obtaining an image; determining the Laplacian matrix of the image; obtaining the a first region of an image, the first region indicating a portion of the image to be color corrected; obtaining a second region of the image; obtaining a first recolored image based on the second region; determining a first corrected region of a first corrected image with the Lass matrix and the first recolored image; and obtaining and outputting a corrected image based on the first corrected region of the first corrected image.

Owner:ALTOSTRATUS CAPITAL LLC

Dyeing low-temperature post-treatment auxiliary of pure polyester fabric and polyester-containing fabrics and post-treatment technology thereof

The invention discloses a dyeing low-temperature post-treatment auxiliary of a pure polyester fabric and polyester-containing fabrics and a post-treatment technology thereof. The post-treatment auxiliary is prepared from the following components: 300-600 g / kg of rongalite, 50-400 g / kg of biological enzyme and 100-500 g / kg of Gemini cationic surface active agent. By compounding the dyeing post-treatment auxiliary of the polyester fabric or the polyester-containing fabric, then using the post-treatment auxiliary for conducting dyeing low-temperature post-treatment on the polyester fabric or thepolyester-containing fabric, and using a synergistic effect mechanism among the three components, low-temperature post-treatment processing is conducted on of the polyester fabric or the polyester-containing fabric is realized, the defect that traditionally, the polyester fabric or the polyester-containing fabric needs to be subjected to post-treatment under a high temperature condition is overcome, dye which is washed into a solution does not stain the fabrics any more, moreover, post-treatment printing and dyeing wastewater is colorless, which is beneficial for wastewater treatment, and thefabrics subjected to post-treatment have soft hand feelings, and are excellent in fastness.

Owner:湖南中翔化学科技有限公司

Method and apparatus for correction of image

ActiveCN108352055AHigh quality cutSave time cuttingImage enhancementImage analysisPattern recognitionComputer graphics (images)

Disclosed is an apparatus comprising a processing device and a method for color correction of an image in a processing device, the method comprising: obtaining an image; determining a Laplacian matrixof the image; obtaining a first region of the image, the first region being indicative of a part of the image to be color corrected; obtaining a second region of the image; obtaining a first recoloring image based on the second region; determining a first corrected region of a first corrected image based on the Laplacian matrix and the first recoloring image; and obtaining and outputting a corrected image based on the first corrected region of the first corrected image.

Owner:ALTOSTRATUS CAPITAL LLC

Devices and methods for processing touch inputs based on their intensities

ActiveCN107850976AImprove satisfactionReduce dosageDigital data processing detailsInput/output processes for data processingDisplay deviceHuman–computer interaction

An electronic device with a display, a touch-sensitive surface, and one or more sensors to detect intensity of contacts with the touch-sensitive surface: displays a first user interface of a first software application, the first user interface including a plurality of user interface objects, a first user interface object of the plurality of user interface objects being associated with an application-independent set of predefined instructions for preview operations; detects a first portion of an input by a contact while a focus selector is over the first user interface object, in the pluralityof user interface objects, on the display; and in response to detecting the first portion of the input and in accordance with a determination that the first portion of the input satisfies predefined criteria, executes the application-independent set of predefined instructions for preview operations.

Owner:APPLE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com