Water-saving washer

A washing machine, water-saving technology, applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of increasing factory production costs, wasting water resources, increasing water consumption, etc., to achieve enhanced structural strength and prolong service life , the effect of increasing tolerance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

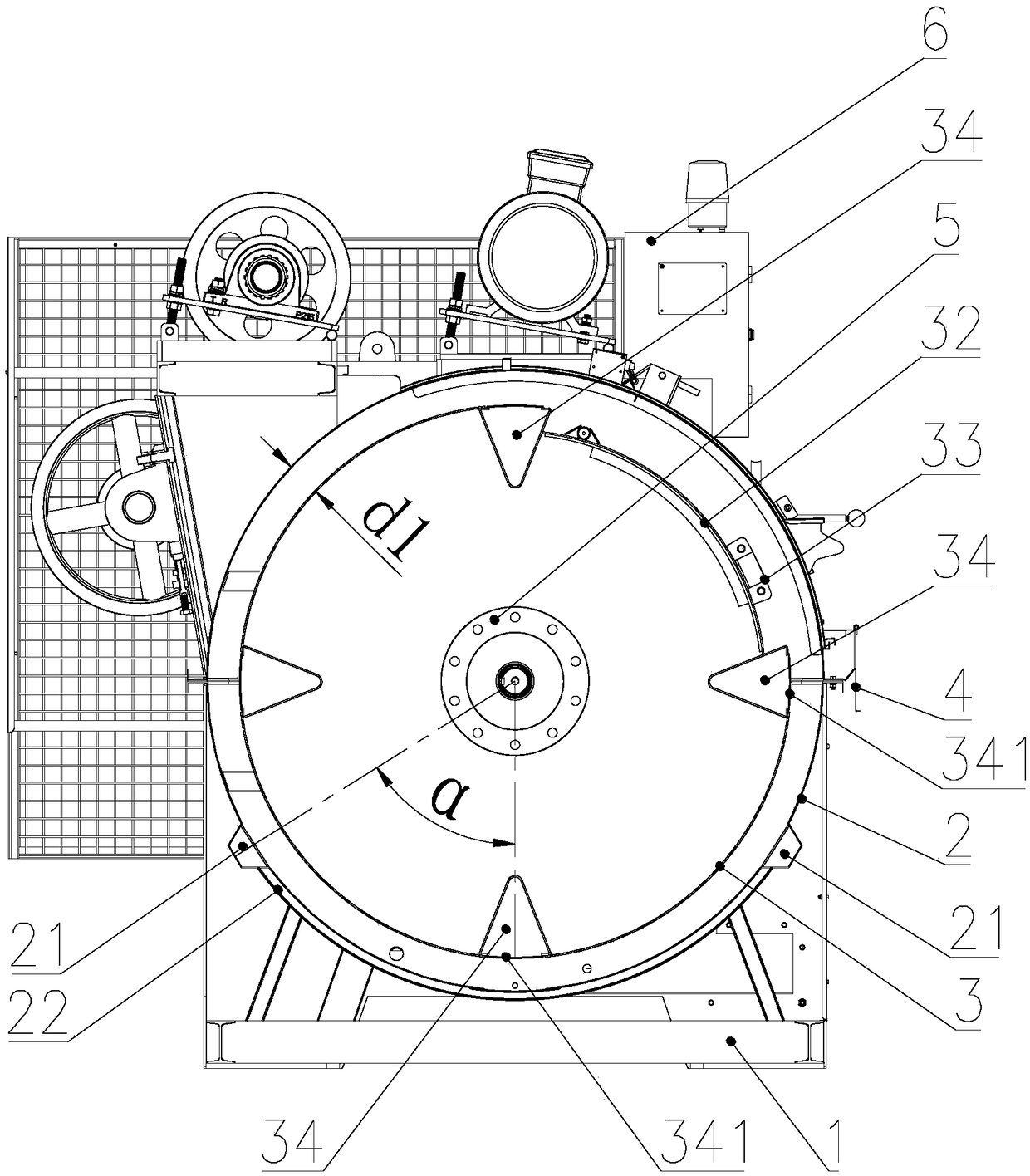

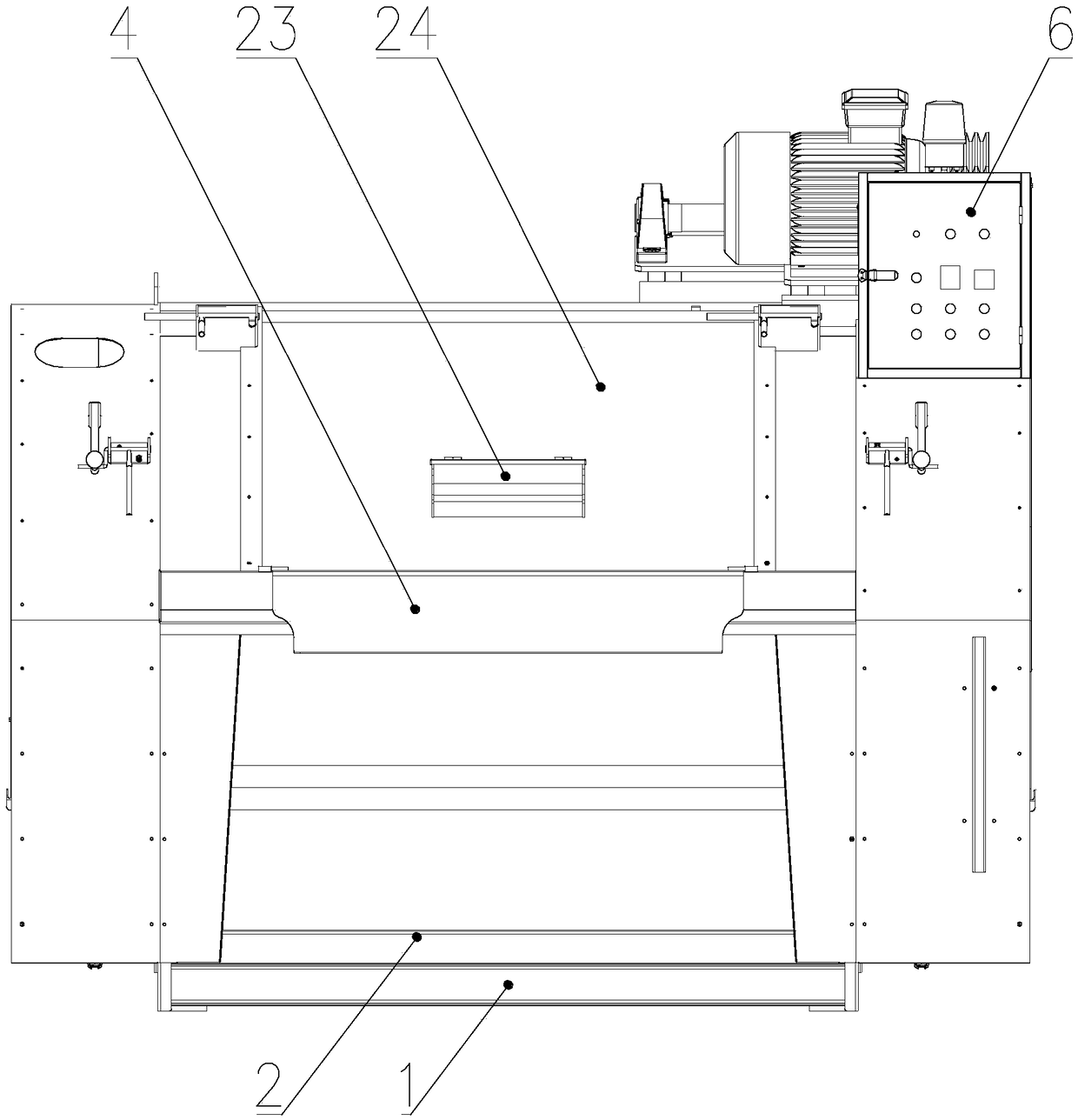

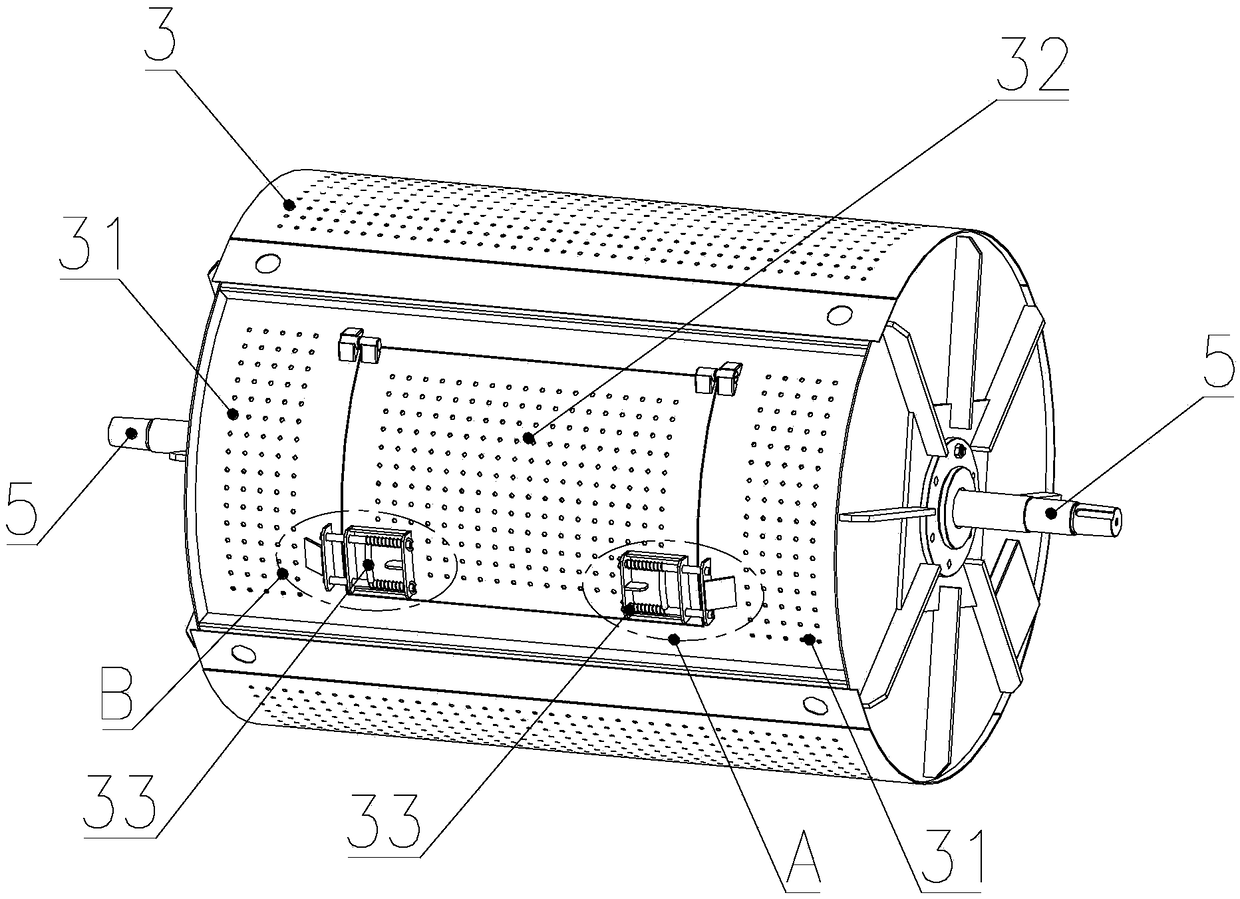

[0065] Such as figure 1 with figure 2 As shown, a water-saving washing machine includes an outer tub 2, an inner tub 3 fixed on a base 1, and a rotating shaft 5 driven by a motor; the inner tub 3 is coaxially and horizontally arranged in the outer tub 2 and is driven by the rotating shaft 5. Driven to rotate; a number of small holes are distributed on the wall of the inner barrel 3, and an inner door 32 is provided on the wall of the inner barrel 3; an outer wall corresponding to the position of the inner door 32 is provided on the wall of the outer barrel 2 Door 24; the inner barrel 3 is provided with a lock 33 for locking the inner door 32; the inner barrel 3 is provided with an inner sink area 31; the inner door 32 is installed on the inner sink area 31; In addition, the distance d1 between the inner tub 3 and the outer tub 2 is 80mm, which satisfies the need for the inner tub 3 to rotate in the outer tub 2 driven by the rotating shaft 5, and avoids excessive water consumpt...

Embodiment 2

[0086] The difference between this embodiment and the first embodiment is that the structure of the inner sink area 31 on the inner barrel 3 is different.

[0087] Such as Figure 4 with Figure 5 As shown, the inner sink area 31 is located in the axial middle area, and the area with a distance d3 of 100 mm from the edge of the inner door 32 is set as the inner sink area 31, and the arc rectangular area is set to be lower than the outer surface of the inner barrel 3. , And ensure that the inner sink area 31 is located in the middle of the inner tub 3, and its axial length accounts for 60% of the length of the inner tub 3. On the one hand, it is ensured that the opening at the inner door 32 provided on the inner sink area 31 is not too small, so that workers can deliver clothes On the other hand, it is ensured to avoid forming a large opening on the inner barrel 3, thereby ensuring the structural strength of the inner barrel 3; in addition, the inner sink area 31 and the edge of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com