Pipeline thread rolling and processing method and roll machine

A processing method and technology of a rolling mill, applied to threaded products, other household appliances, household appliances, etc., can solve the problems of poor sealing performance of pipeline threads, increased use costs, low tensile strength, etc., and achieve reasonable structure, Improved efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

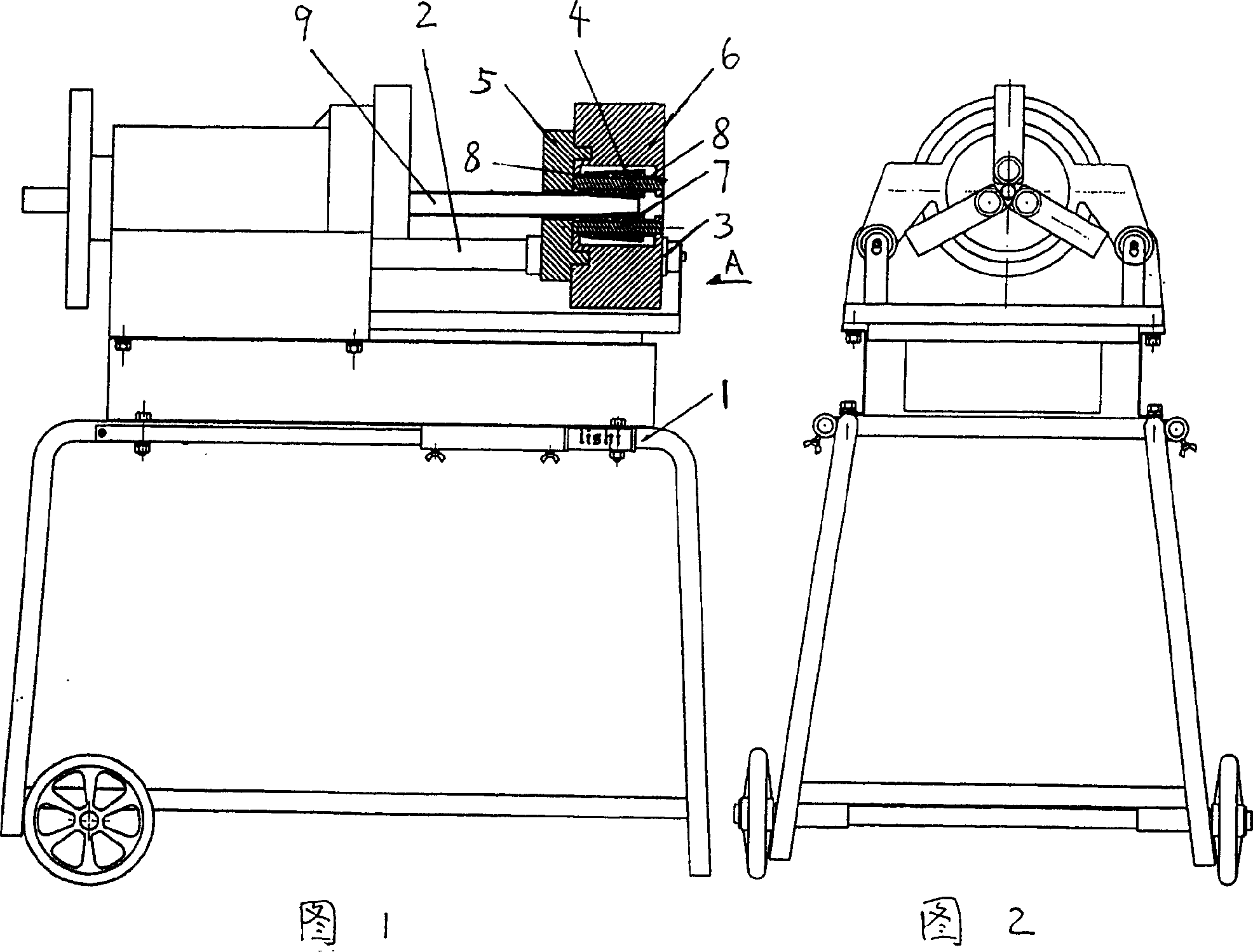

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings: the pipe thread rolling machine described in the present invention is improved on the basis of the original threading machine, as shown in the figure. It consists of machine base 1, motor on the machine base, reducer, guide post positioning mechanism, and workpiece clamping mechanism. A frame 3 is provided with a thread rolling mechanism with a built-in rolling wheel 4 on the slide frame 3 . The thread rolling mechanism includes a plane screw disk 5, which is fixed on the carriage 3. On the plane screw disk 5, there are radially arranged roller frames 6 with three adjustable torque inner ends equipped with rolling wheels 4 according to a center angle of 120 degrees; the plane screw disk 5 can control the radial movement of the three roller frames 6 , to accommodate tubes of different sizes. The inner end of the roller frame 6 passes through a roller shaft 7, on which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com