Environment-friendly water-based DTY oiling agent as well as application and application method thereof

An environmentally friendly, water-based technology, applied in the chemical post-processing of synthetic polymer rayon filaments, etc., can solve the problems of inability to degrade the environment under natural conditions, incomplete antistatic properties of oil agents, and non-renewable raw material resources. Effectiveness of work and product grade, low oil application, reduced handling cost and effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

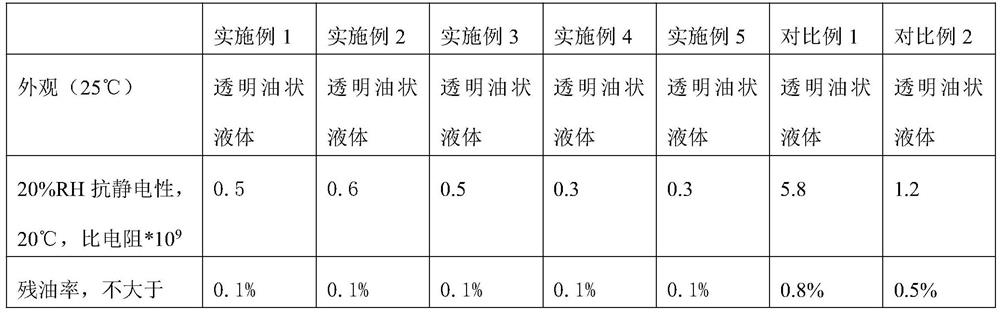

Examples

Embodiment 1

[0021] The environment-friendly water-based DTY oil agent comprises the following raw materials in parts by weight: 10 parts of vegetable oil, 20 parts of alcohol ether, 4 parts of surfactant and 80 parts of water.

[0022] The application of the environment-friendly water-based DTY oil agent is applied to polyester DTY yarn, polyester plus nylon textured yarn, polyester plus spandex textured yarn, nylon textured yarn or cationic textured yarn.

[0023] The use method of the environment-friendly water-based DTY oil agent is to add the oil agent to the oil tank of the textured machine, and oil it through the tanker. The oiling rate: polyester DTY yarn ≥ 1%; polyester plus spandex textured yarn, nylon textured yarn or Cationic textured silk ≥ 1.5%.

Embodiment 2

[0025] The environment-friendly water-based DTY oil agent comprises the following raw materials in parts by weight: 12 parts of soybean oil, 12 parts of alcohol ether, 3 parts of fatty acid polyoxyethylene methyl ether and 70 parts of water.

[0026] The application of the environment-friendly water-based DTY oil agent is applied to polyester DTY yarn, polyester plus nylon textured yarn, polyester plus spandex textured yarn, nylon textured yarn or cationic textured yarn.

[0027] The use method of the environment-friendly water-based DTY oil agent is to add the oil agent to the oil tank of the textured machine, and oil it through the tanker. The oiling rate: polyester DTY yarn ≥ 1%; polyester plus spandex textured yarn, nylon textured yarn or Cationic textured silk ≥ 1.5%.

Embodiment 3

[0029] The environment-friendly water-based DTY oil agent comprises the following raw materials in parts by weight: 15 parts of rapeseed oil, 10 parts of alcohol ether, 9 parts of fatty acid polyoxyethylene methyl ether and 65 parts of water.

[0030] The application of the environment-friendly water-based DTY oil agent is applied to polyester DTY yarn, polyester plus nylon textured yarn, polyester plus spandex textured yarn, nylon textured yarn or cationic textured yarn.

[0031] The use method of the environment-friendly water-based DTY oil agent is to add the oil agent to the oil tank of the textured machine, and oil it through the tanker. The oiling rate: polyester DTY yarn ≥ 1%; polyester plus spandex textured yarn, nylon textured yarn or Cationic textured silk ≥ 1.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com