A washing method of a micro atomization washing machine and a washing machine adopting the method

A washing machine and trace technology, applied in the direction of centrifugal force liquid/gas/vapor removal, liquid/gas/vapor fabric treatment, and textile material processing equipment configuration, etc. Resource waste and other issues, to achieve the effect of reducing water consumption, reducing the risk of cross-dying of clothes, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

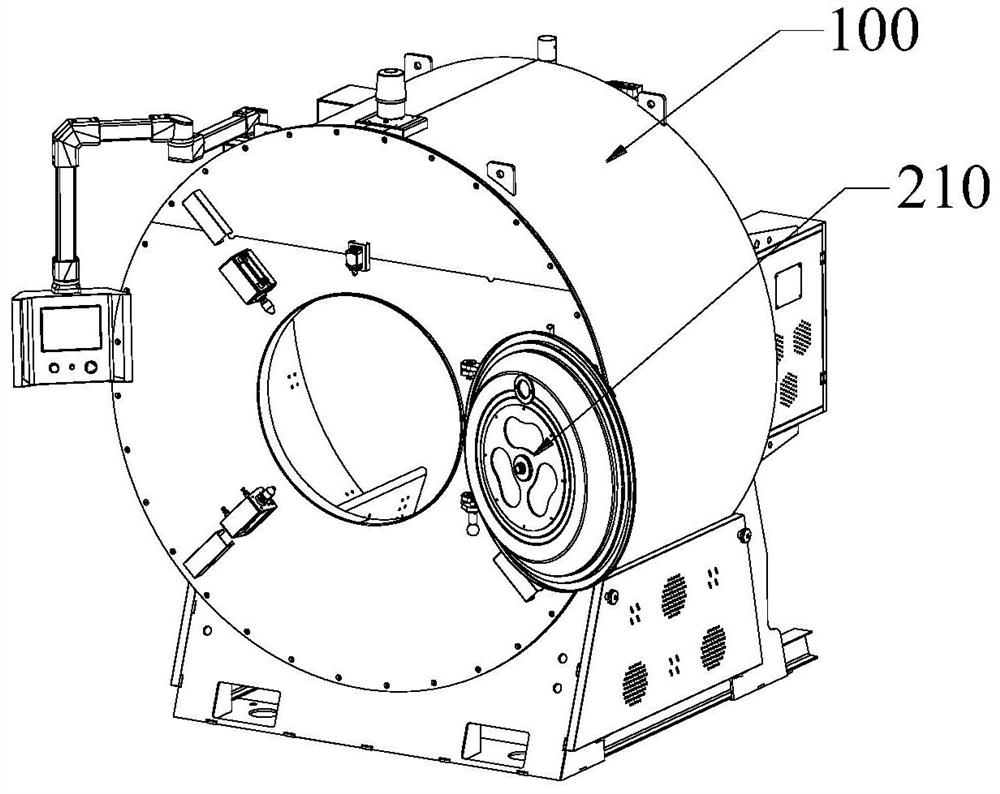

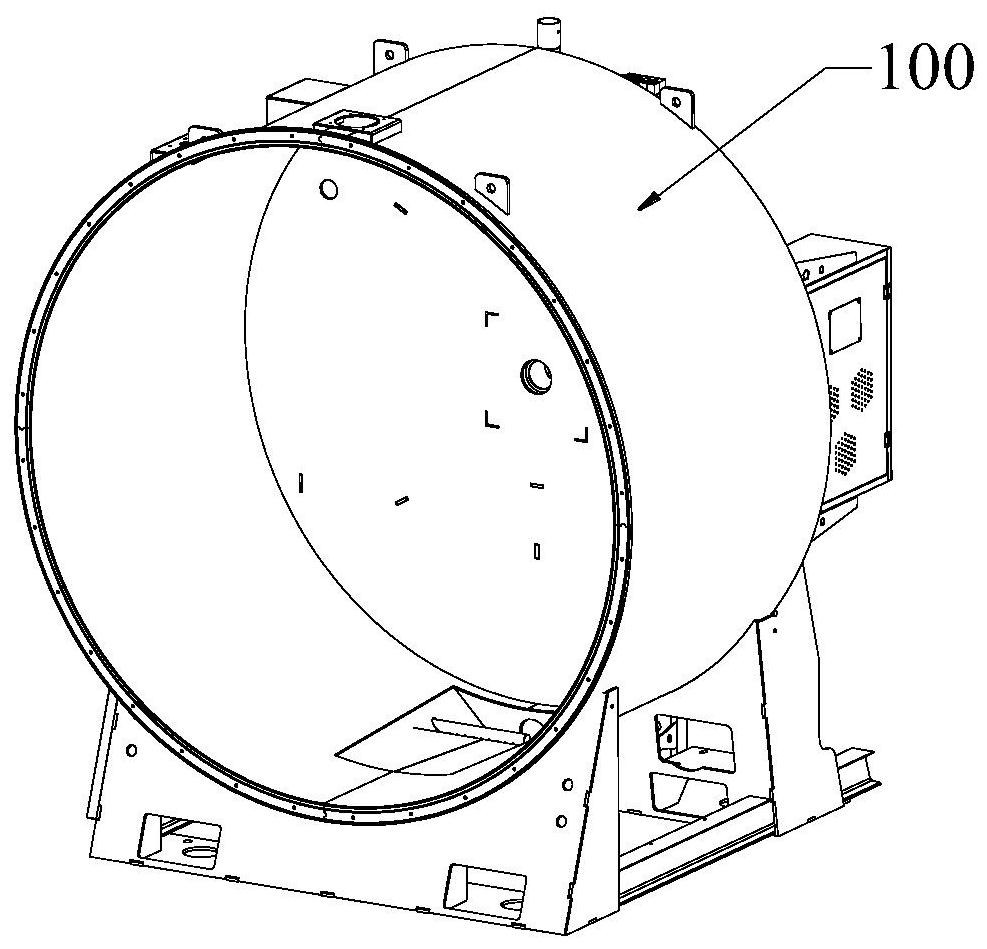

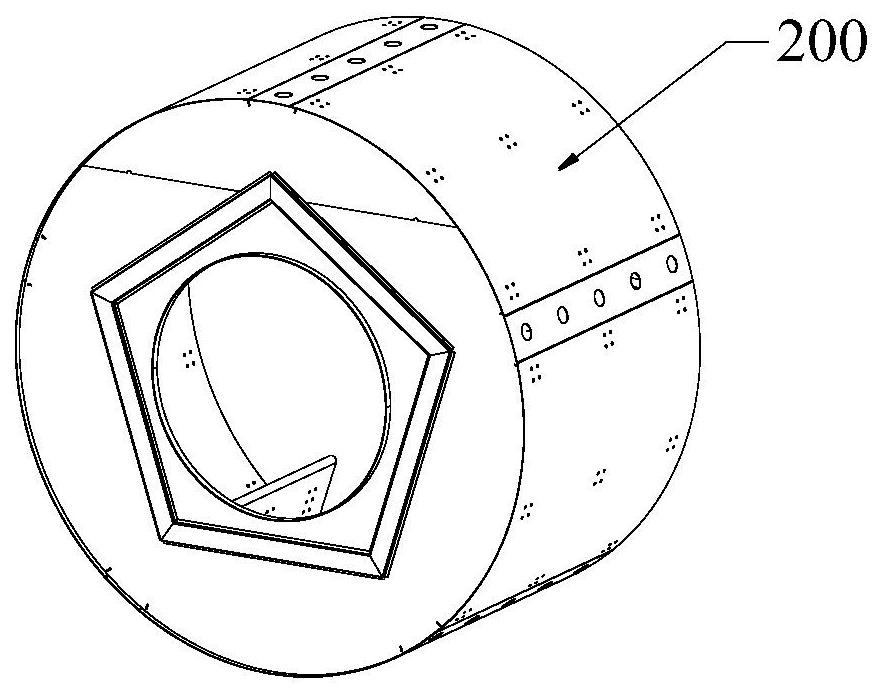

[0054] Such as Figure 1~3 As shown, the structural diagram of a micro atomization water washing machine in this embodiment includes an outer tub 100 fixed on the machine base, an inner tub 200 and a rotating shaft driven by a motor; the inner tub 200 is arranged coaxially and horizontally in the outer tub 100 , and rotated by the drive of the rotating shaft; the inner barrel 200 and the outer barrel 100 are provided with a barrel door 210 at the mouth of the barrel, and the barrel door 210 is provided with a spray head 211 facing into the barrel.

[0055] In this embodiment, the washing machine is mainly composed of an outer tub 100 fixed on the base, an inner tub 200 and a rotating shaft driven by a motor, the inner tub 200 and the outer tub 100 are connected to the rotating shaft, and the rotating shaft is driven by the motor to rotate , the inner barrel 200 is arranged in the outer barrel 100, and the outer barrel 100 and the inner barrel 200 are placed horizontally. Such...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com