A Method for Dynamically Controlling the Periodic Micro-Nano Structure of Crystalline Silicon Surface Based on Square Hole Assisted Electrons

A technology of electronic dynamic control and micro-nano structure, which is applied in the field of femtosecond laser applications, can solve the problems of inability to efficiently control the processing of periodic micro-nano structures on the surface, so as to improve processing accuracy and efficiency, reduce energy consumption, and reduce processing power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

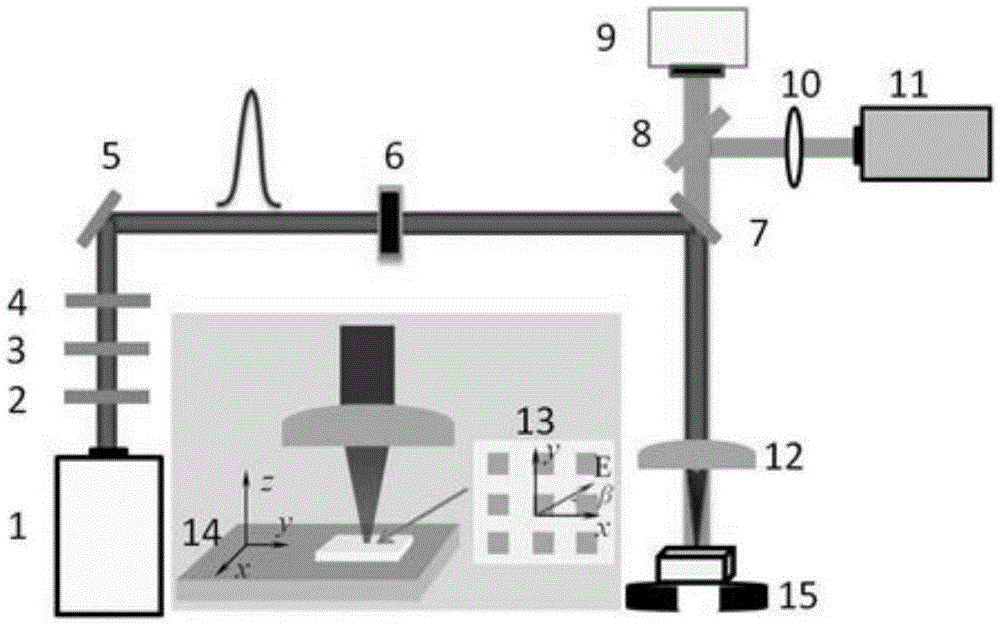

[0051] (1) Under a specific energy, by controlling the femtosecond laser direct writing speed and then adjusting the energy deposited on the surface of the material per unit area, the surface periodic micro-nano structure can be controlled. Specifically, the copper mesh with square holes is selected as a side length of 19 μm, and a 100mm plano-convex lens is used, at 0.1J / cm 2 Under the energy density of 1000Hz, the pulse repetition frequency is 1000Hz, the laser direct writing speed is increased from 100μm / s to 1000μm / s at intervals of 100, keeping the linear polarization direction parallel to the x-axis (one edge of the square hole), passing through the square hole The final focused femtosecond laser pulse regulates the excitation characteristics of the local instantaneous electronic dynamics in a specific area of the irradiated area, so that the single crystal silicon can obtain different surface periodic micro-nano structures under the action of the direct writing femtose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com