Instant accelerating agent for reactive dye and application method of instant accelerating agent

A technology of reactive dyes and application methods, applied in the field of reactive dye instant dye accelerators, can solve the problems of unfavorable growth and development of enterprises, slow dissolution of Yuanming powder and soda ash, and high labor intensity of operators, so as to reduce the labor intensity of workers and reduce The number of times of washing, the effect of solving the dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

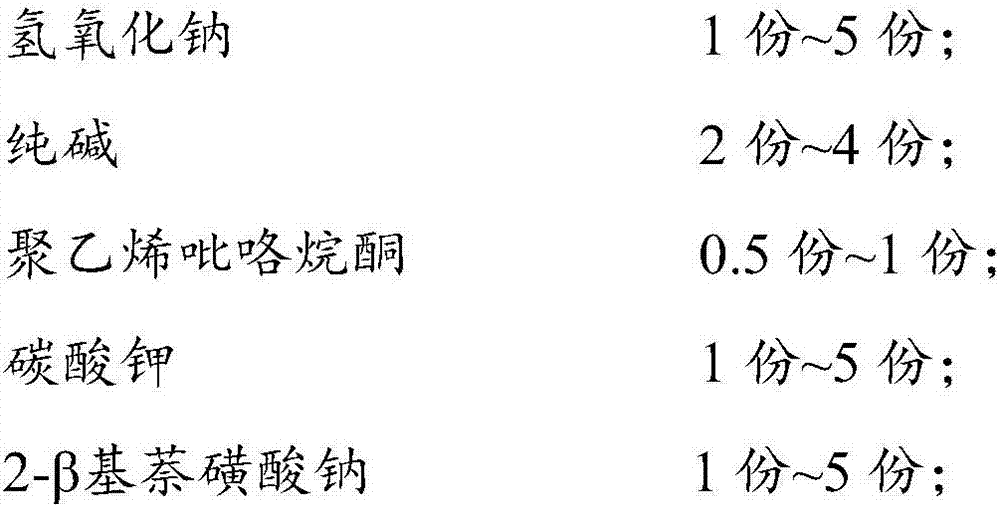

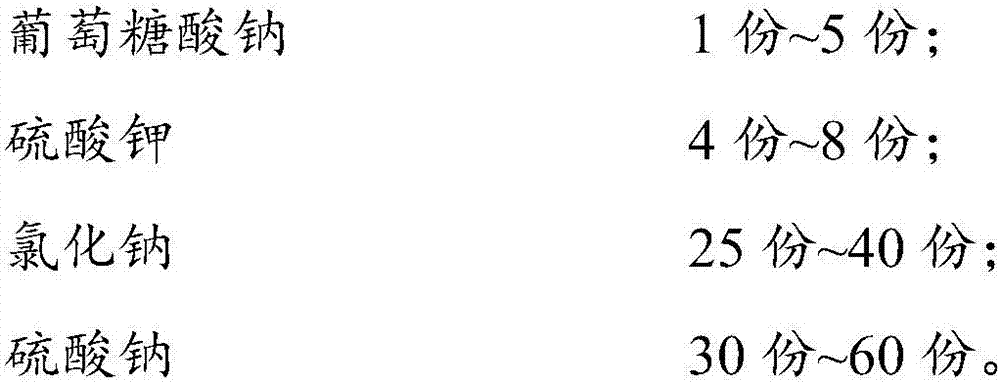

[0025] Embodiment 1, this embodiment provides a kind of reactive dye instant dyeing accelerator

[0026] First, weigh 1 part of sodium hydroxide, 1 part of potassium carbonate, 1 part of sodium 2-beta naphthalenesulfonate, 1 part of sodium gluconate, 4 parts of potassium sulfate, 25 parts of sodium chloride, and 30 parts of sodium sulfate according to parts by weight , 2 parts of soda ash, and 0.75 parts of polyvinylpyrrolidone are then added to deionized water, and after complete reaction, an instant dye accelerator for reactive dyes is obtained.

[0027] Then, prepare the dyeing bath according to 1:15, add leveling agent and additive (leveling agent, additive can be added or not) at room temperature, stir, and run for 10 minutes; then, add reactive dye at room temperature, put Put into the cellulose fiber fabric after scouring and bleaching, soak and run for 20 minutes, then add reactive dye fast-dissolving dye accelerator, the addition amount of reactive dye instant dye acc...

Embodiment 2

[0028] Embodiment 2, the present embodiment provides a kind of reactive dye instant dyeing accelerator

[0029] First take by weight 5 parts of sodium hydroxide; 5 parts of potassium carbonate; 5 parts of sodium 2-beta naphthalene sulfonate; 5 parts of sodium gluconate; 8 parts of potassium sulfate; 40 parts of sodium chloride; 60 parts of sodium sulfate ; 2 parts of soda ash; 0.75 parts of polyvinylpyrrolidone, and then added to deionized water, after complete reaction, to obtain instant dyeing accelerator for reactive dyes.

[0030] Then, prepare a dyeing bath according to 1:15, add reactive dyes at room temperature, put into the cellulose fiber fabric after scouring and bleaching, soak and run for 20 minutes, then add one-third of the reactive dye instant dyeing accelerator, 15 After 10 minutes, put in the remaining two-thirds of the dyeing accelerator and run for 10 minutes. The ratio of the added amount of the reactive dye instant dyeing accelerator to the reactive dye is...

Embodiment 3

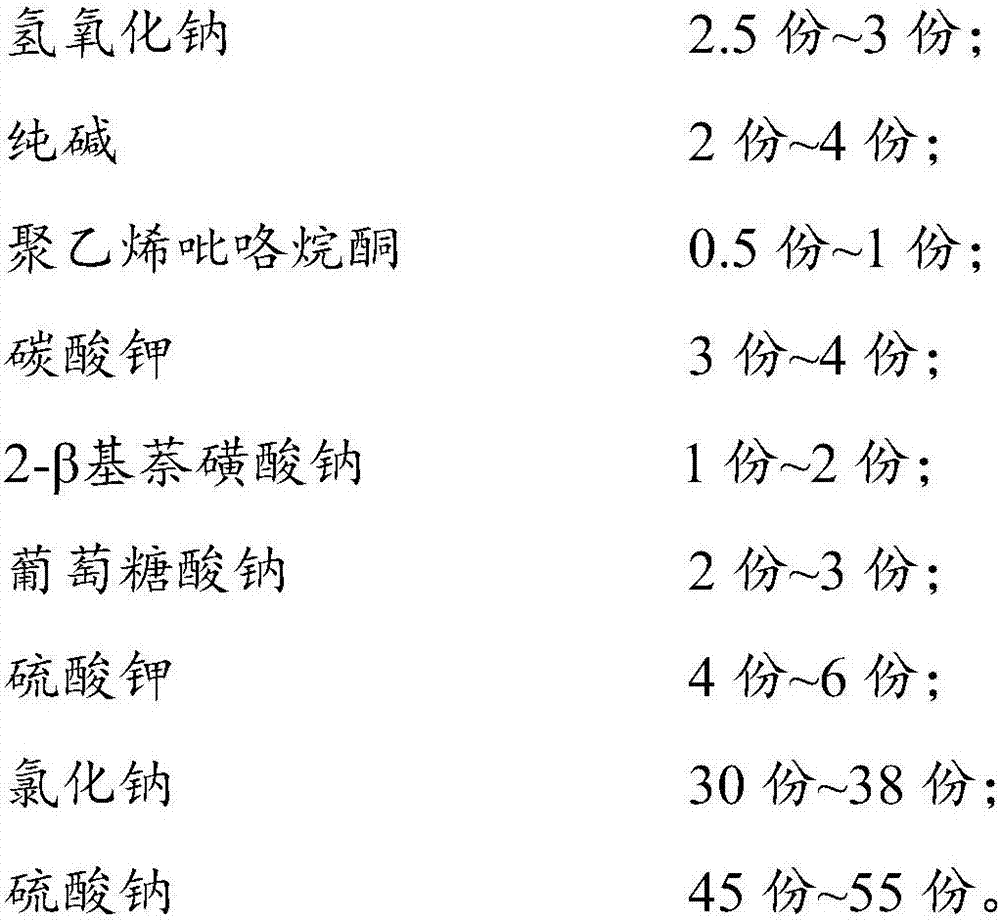

[0031] Embodiment 3, the present embodiment provides a kind of reactive dye instant dyeing accelerator

[0032] First take by weight 2.5 parts of sodium hydroxide, 3 parts of potassium carbonate, 2 parts of soda ash, 0.75 parts of polyvinylpyrrolidone, 1 part of sodium 2-beta naphthalenesulfonate, 2 parts of sodium gluconate, 5 parts of potassium sulfate, 36.5 parts of sodium chloride and 50 parts of sodium sulfate are then added into deionized water, and after complete reaction, an instant dye accelerator for reactive dyes is obtained.

[0033] Then, prepare the dyeing bath according to 1:15, add leveling agent and dyeing agent at room temperature, stir, and run for 10 minutes; then, add reactive dyes at room temperature, put the cellulose fiber fabric after scouring and bleaching, and soak for 20 minutes Finally, add reactive dye fast-dissolving accelerator, the addition amount of reactive dye instant dye-accelerating agent, and the ratio of reactive dye is 5:1, after 15 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com