Low-glue-application-amount wood single composite low-temperature plasma processing equipment and operation method

A technology of low-temperature plasma and composite materials, which is applied in the field of plasma treatment equipment, can solve the problems of unsuitable industrial continuous treatment of thick wood materials, and achieve the effects of low treatment cost, strong controllability and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

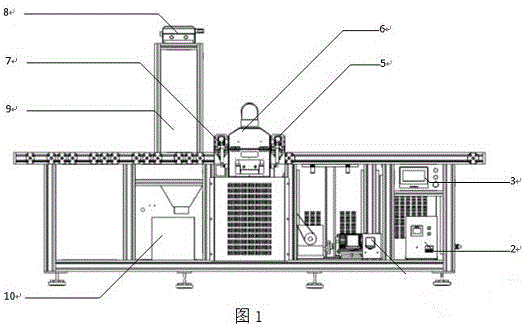

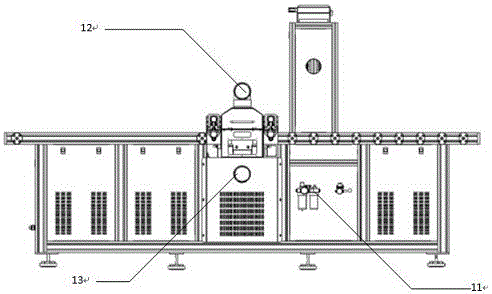

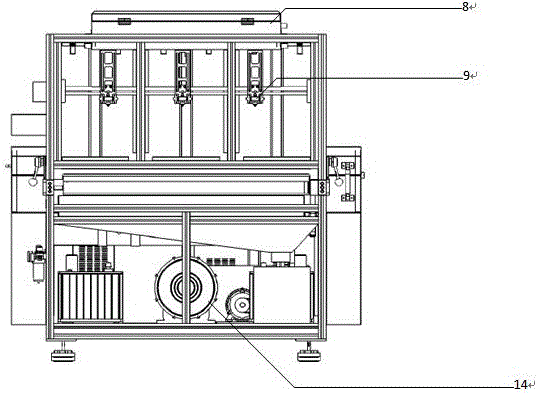

[0025] The present invention is described in detail below in conjunction with accompanying drawing.

[0026] like Figure 1-6 As shown, the present invention provides a low-temperature plasma processing equipment for single-composite wood materials with low glue sizing, including a low-temperature plasma electrode base 6, a low-temperature plasma power supply 2 and a body, the body is assembled from a profile frame, and the low-temperature The plasma electrode base 6 is installed between the belt conveyor platform 17 and the roller conveyor platform 18, and is fixed in the middle of the body. The belt conveyor platform 17 is installed on the front end of the body and fixed on the profile frame. The roller conveyor platform 18 is installed The tail end of the body is fixed on the profile frame, and the micro-glue device 9 is installed on the profile frame, which is located at the rear end of the low-temperature plasma electrode base 6, above the roller conveying platform 18, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com