Edge sealing conductive substrate and electrochromic device

A conductive matrix, edge sealing technology, used in instruments, nonlinear optics, optics, etc., can solve the problems of uneven color change, bending, easy to be affected by water and oxygen, and achieve the effect of easy connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] This embodiment provides a rectangular parallelepiped electrochromic device, which includes a first conductive layer, a color-changing material layer and a second conductive layer stacked in sequence.

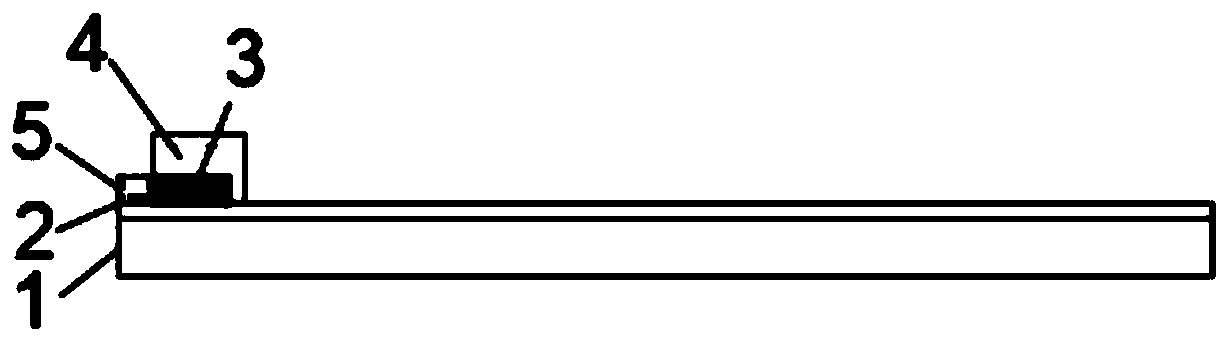

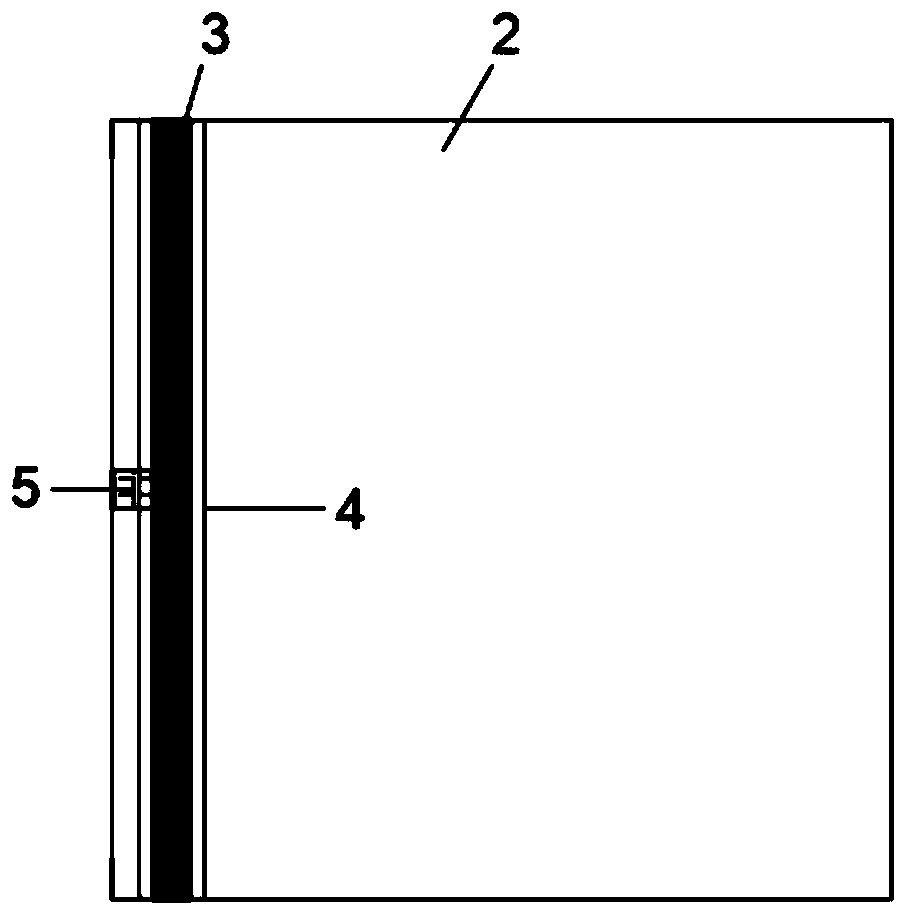

[0070] The side view of the first conductive layer and the second conductive layer is as follows figure 1 As shown, the top view of the first conductive layer and the second conductive layer is as follows figure 2 shown.

[0071] The first conductive layer is an edge-sealed conductive substrate, including a base layer 1, a transparent conductive layer 2, a rectangular conductive part 3, a sealing part 4, and a side lead-out electrode 5 connected to the conductive part 3; transparent conductive The layer 2 is stacked on the top surface of the base layer 1 , the bottom of the conductive part 3 is connected to the top surface of the transparent conductive layer 2 ; the sealing part 4 is connected to the top surface of the transparent conductive layer 2 and covers the cond...

Embodiment 2

[0078] This embodiment provides a rectangular parallelepiped electrochromic device, which includes a first conductive layer, a color-changing material layer and a second conductive layer stacked in sequence.

[0079] The side view of the first conductive layer and the second conductive layer is as follows Figure 4 As shown, compared with Example 1, the top surface of the sealing part 4 of the first conductive layer provided by this embodiment is provided with a release film layer 6, and the top surface of the sealing part 4 of the second conductive layer is provided with a release film layer 6 .

[0080] In this embodiment, the setting of the release film layer 6 makes the first conductive layer and the second conductive layer convenient for storage and transportation. When it is necessary to use the first conductive layer and the second conductive layer to prepare an electrochromic device, only the release film layer needs to be peeled off. 6 is enough.

Embodiment 3

[0082] This embodiment provides a rectangular parallelepiped electrochromic device, which includes a first conductive layer, a color-changing material layer and a second conductive layer stacked in sequence.

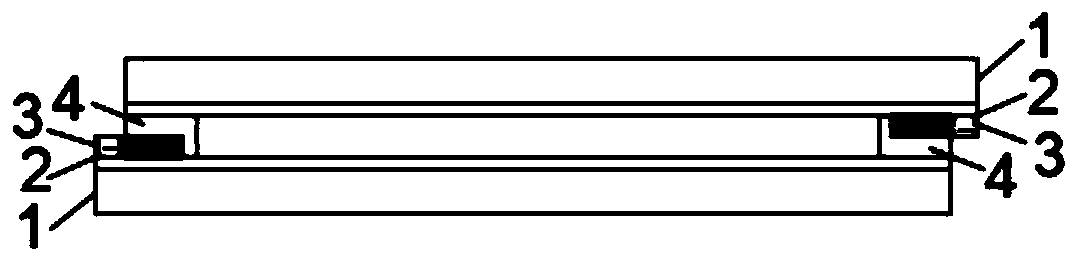

[0083] The top view of the first conductive layer and the second conductive layer is as follows Figure 5 As shown, the side view of the first conductive layer and the second conductive layer is shown as Figure 6 shown.

[0084] The first conductive layer is an edge-sealed conductive substrate, including a base layer 1, a transparent conductive layer 2, two rectangular conductive parts 3, a sealing part 4, and two side lead-out electrodes 5 connected to the conductive parts 3; two rectangular conductive Part 3 is connected in an L shape, and each side of the L-shaped conductive part 3 is connected with a side lead-out electrode 5, one end of the side lead-out electrode 5 is connected to the conductive part 3, and the other end is flush with the edge of the edge-sealed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com