Photochromic lens with double optical film layers and preparation method of photochromic lens

A color-changing lens and photochromic technology, which is applied in the direction of coating, optics, optical components, etc., can solve the problems of uneven coating thickness of sub-sheets, affecting the wearing effect, and deep color change, so as to overcome the unevenness of the double optical film Sexuality, surface shape and gloss are not affected, and the effect of discoloration is uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

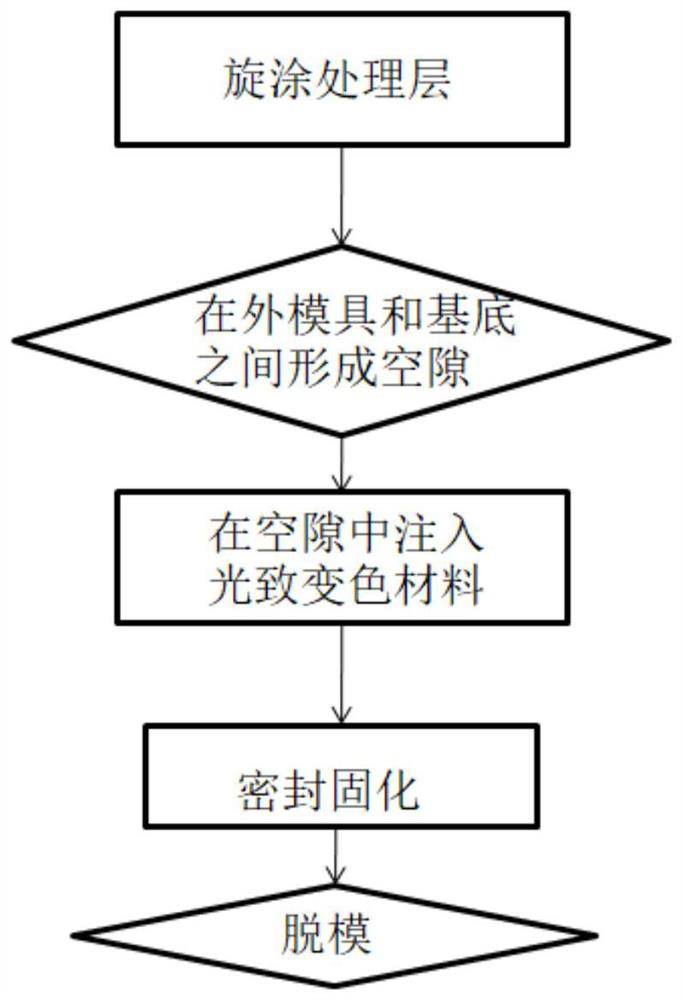

Method used

Image

Examples

Embodiment 1

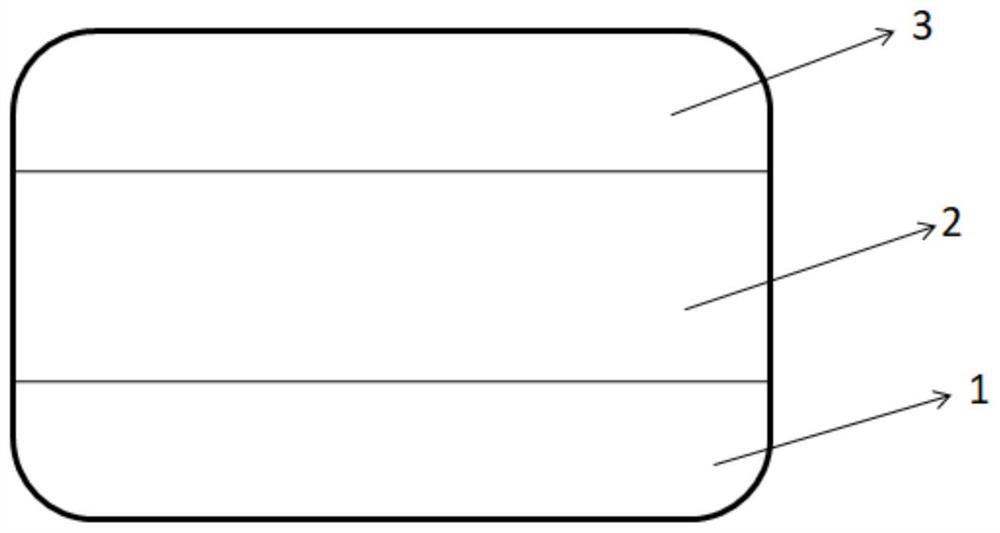

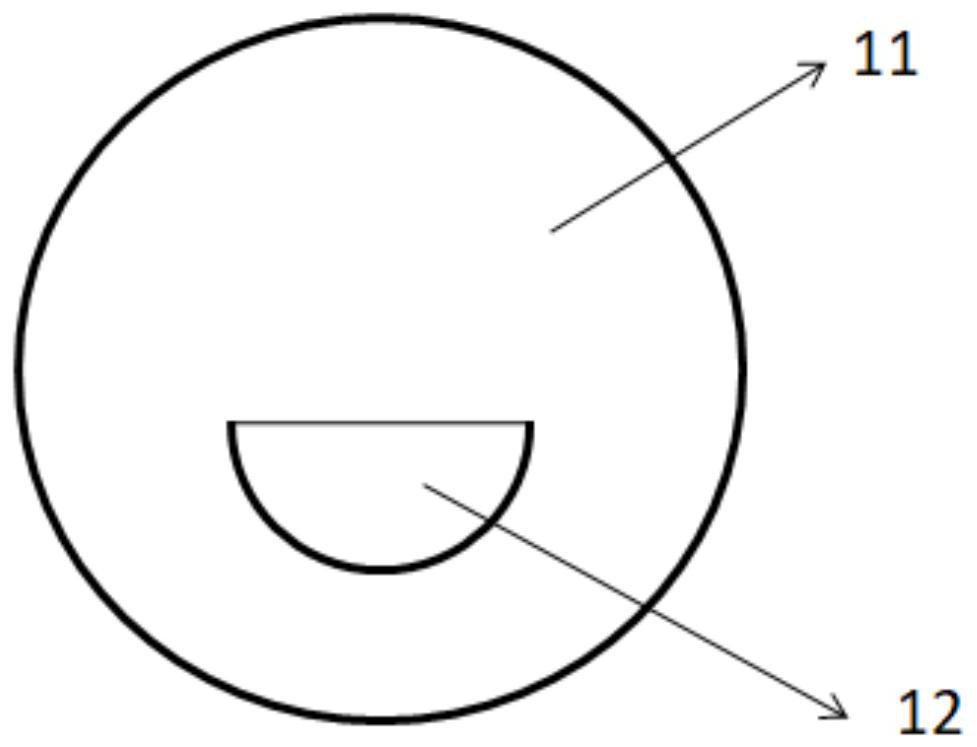

[0059] A kind of dioptic film photochromic lens, such as figure 2 As shown, the double photochromic lens includes from the inside to the outside: a base 1, a treatment layer 2 and a photochromic layer 3; the photochromic layer 3 is cured on the surface of the treatment layer 2 by ultraviolet light irradiation, wherein, calculated according to the mass fraction, The photochromic layer 3 includes the following components: propoxylated bisphenol A dimethacrylate 30% containing 2 to 20 repeating units of propoxy; 2 to 20 repeating units containing propoxy 60% of polyethylene glycol diacrylate; 10% of pentaerythritol tetraacrylate; the rest are photoinitiators, 100% in total, calculated in parts by weight, the material of the treatment layer includes the following components: bisphenol A epoxy acrylic resin 50 parts, 5 parts of dioctyl adipate, 2 parts of vinyltrimethoxysilane and 1 part of tetrabutylammonium chloride, such as image 3 As shown, the base 1 is a one-line bifocal l...

Embodiment 2

[0067] A kind of dioptic film photochromic lens, such as figure 2 As shown, the double photochromic lens includes from the inside to the outside: a base 1, a treatment layer 2 and a photochromic layer 3; the photochromic layer 3 is cured on the surface of the treatment layer 2 by ultraviolet light irradiation, wherein, calculated according to the mass fraction, The photochromic layer 3 includes the following components: 40% of ethoxylated bisphenol A dimethacrylate containing 2 to 20 repeating units of ethoxy groups; 45% of polyethylene glycol diacrylate; dipentaerythritol 15% of hydroxypentaacrylate; the rest are photoinitiators, 100% in total, calculated in parts by weight, the material of the treatment layer includes the following components: 60 parts of bisphenol A epoxy acrylic resin, 6 parts of dioctyl adipate , 4 parts of vinyltrimethoxysilane and 2 parts of tetrabutylammonium chloride, such as Figure 4 As shown, the base 1 is a flat-top bifocal lens, including a mai...

Embodiment 3

[0076] A kind of dioptic film photochromic lens, such as figure 2 As shown, the double photochromic lens includes from the inside to the outside: a base 1, a treatment layer 2 and a photochromic layer 3; the photochromic layer 3 is cured on the surface of the treatment layer 2 by ultraviolet light irradiation, wherein, calculated according to the mass fraction, The photochromic layer 3 includes the following components: 55% alkoxylated bisphenol A dimethacrylate containing 2 to 20 repeating units of epoxy and propoxy groups; 2 to 20 repeating units containing ethoxy groups; 35% of polyethylene glycol diacrylate with 20 repeating units; 10% of dipentaerythritol hydroxypentaacrylate; the rest are photoinitiators, 100% in total; calculated in parts by weight, the material of the treatment layer includes the following components: bis 75 parts of phenol A epoxy acrylic resin, 7 parts of dioctyl adipate, 4 parts of vinyltrimethoxysilane and 2 parts of tetrabutylammonium chloride, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com