Method of driving electrochromic device

An electrochromic and driving voltage technology, used in instruments, static indicators, etc., can solve the problems of accelerating the coloring speed and accelerating the damage rate of electrochromic components, so as to extend the service life, shorten the discoloration time, and achieve uniform discoloration performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a more complete and clear disclosure of the technical content used in the present invention, the purpose of the invention and the effects achieved, it will be described in detail below, and please also refer to the disclosed drawings and figure numbers:

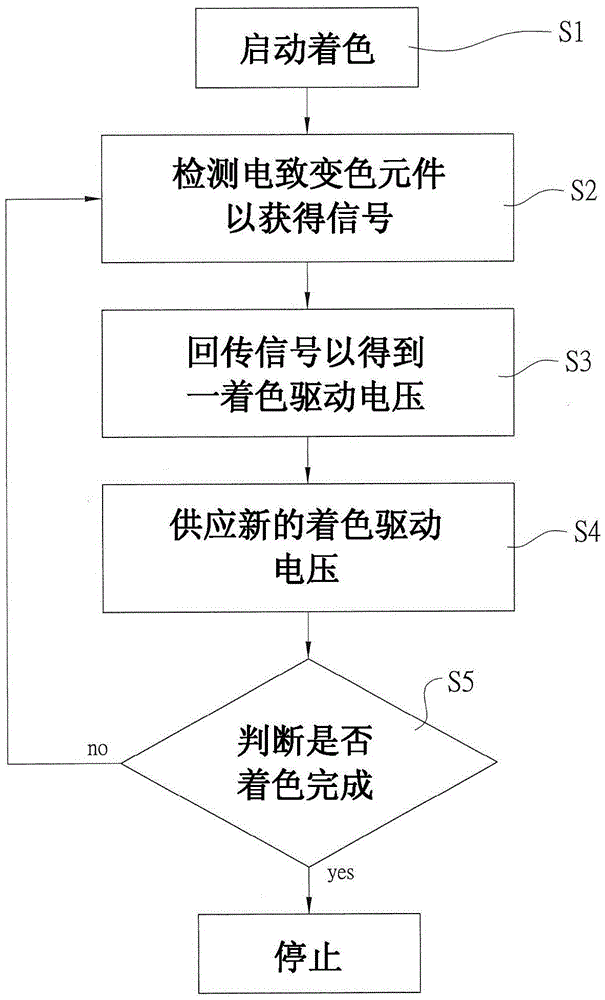

[0029] Please see figure 1 As shown, it is a schematic diagram of the control flow of the method for driving the electrochromic element of the present invention.

[0030] The method for driving electrochromic element of the present invention, its step comprises:

[0031] S1: start coloring, input a coloring driving voltage to an electrochromic element, and make the electrochromic element start to color;

[0032] S2: Detect the electrochromic element to obtain a signal. During the coloring process of the electrochromic element, detect the electrochromic element and generate a signal corresponding to the detection state;

[0033] S3: Return the signal to obtain a coloring driving voltage, detect the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com