Color-changing resin spectacle lens and preparation method thereof

A technology of resin spectacle lenses and resin lenses, applied in the field of lenses, can solve the problems of poor film discoloration durability, complicated process, poor control of lens quality, etc., and achieve stable discoloration performance, uniform discoloration, and good discoloration depth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

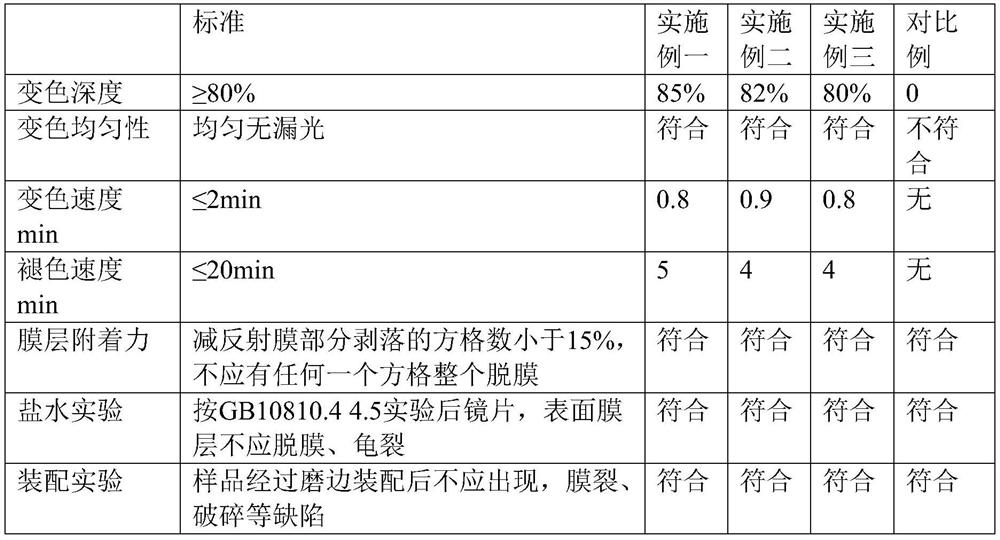

Embodiment 1

[0030] The surface of the resin lens base is dip-coated with a silicone hardening solution to harden the front and rear surfaces by dip coating, and then cured in an oven at a high temperature of 110°C for 3.5 hours to obtain a hardened layer on the surface of the resin lens base.

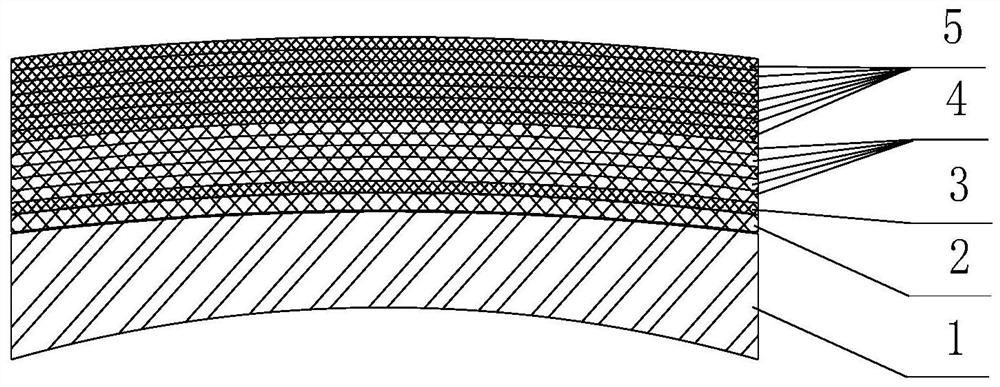

[0031] Put the above lens with a hardened layer into the vacuum coating chamber for vacuum coating, and successively evaporate the isolation layer, the organic color-changing layer and the anti-reflection coating layer;

[0032] Specifically: the first layer of isolation layer is evaporated SiO with a thickness of 150nm 2 ;

[0033] The second to sixth layers of organic color-changing layers are flash-evaporated and vacuum-sprayed sequentially from the inside to the outside, with a thickness of 135nm for benzopyran color-changing layers, a thickness of 65nm for fulgidic anhydride color-changing layers, a thickness of 110nm for benzopyran color-changing layers, and a thickness of 85nm fulgidic anhy...

Embodiment 2

[0039] The surface of the resin lens base is dip-coated with a silicone hardening solution to harden the front and rear surfaces by dip coating, and then cured in an oven at a high temperature of 110°C for 3.5 hours to obtain a hardened layer on the surface of the resin lens base.

[0040] Put the above lens with a hardened layer into the vacuum coating chamber for vacuum coating, and successively evaporate the isolation layer, the organic color-changing layer and the anti-reflection coating layer;

[0041] Specifically, the thickness of the vapor-deposited first layer of isolation layer is 100nmSiO2;

[0042] The second to sixth layers of organic color-changing layers are vapor-deposited from the inside to the outside in sequence, from the benzopyran color-changing layer with a thickness of 140nm, the fulgidic anhydride color-changing layer with a thickness of 70nm, the benzopyran color-changing layer with a thickness of 105nm, and the fulgiane color-changing layer with a thic...

Embodiment 3

[0048] The surface of the resin lens base is dip-coated with a silicone hardening solution to harden the front and rear surfaces by dip coating, and then cured in an oven at a high temperature of 110°C for 3.5 hours to obtain a hardened layer on the surface of the resin lens base.

[0049] Put the above lens with a hardened layer into the vacuum coating chamber for vacuum coating, and successively evaporate the isolation layer, the organic color-changing layer and the anti-reflection coating layer;

[0050] Specifically, the first layer of isolation layer is evaporated to SiO 2 , whose thickness is 150nm;

[0051] The second to sixth layers of organic color-changing layers are vapor-deposited from the inside to the outside in sequence from a benzopyran color-changing layer with a thickness of 135nm, a fulgidic anhydride color-changing layer with a thickness of 70nm, a benzopyran color-changing layer with a thickness of 110nm, and a fulgine color-changing layer with a thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com