Flexible electrochromic device and preparation method thereof

An electrochromic and chromogenic technology, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of uneven discoloration, research on flexible electrochromic devices that needs to be deepened, and functions that cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] (1) Material:

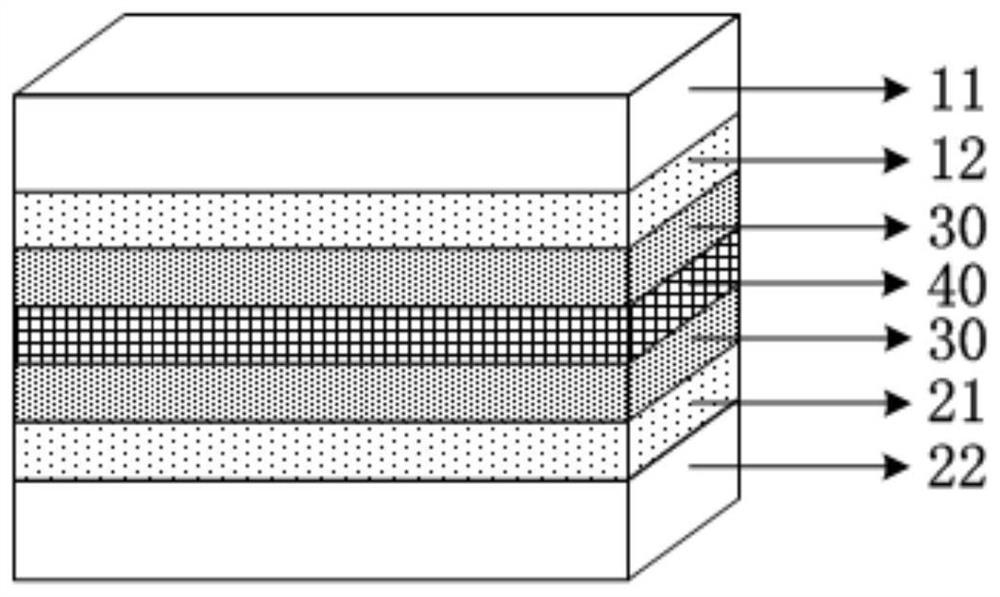

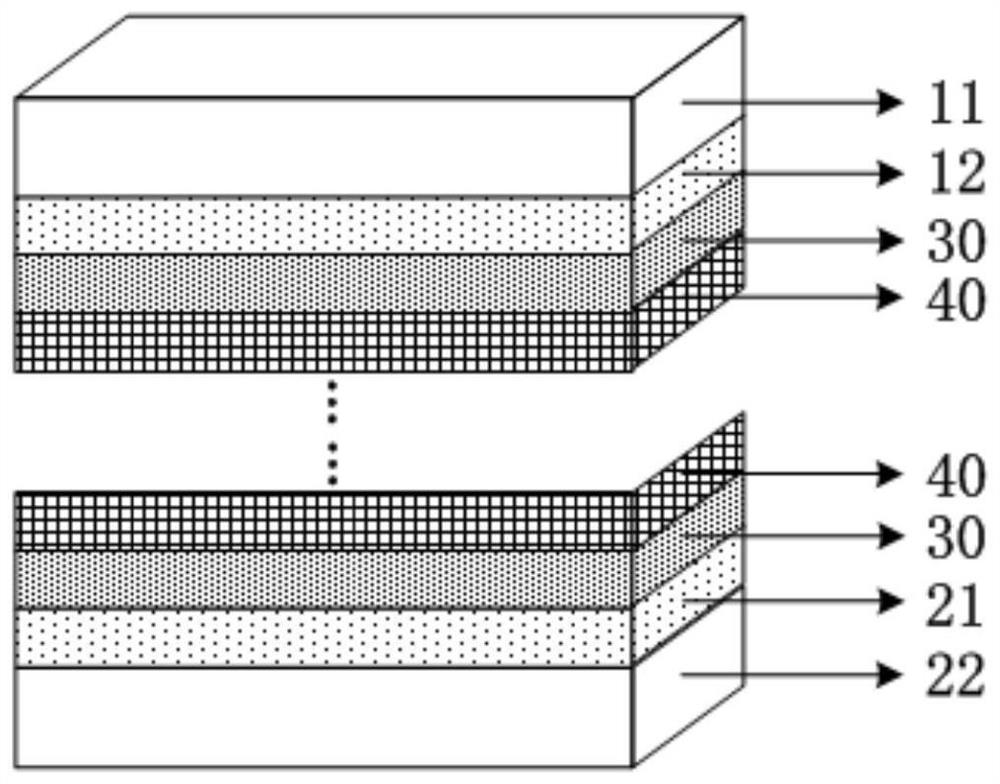

[0060] The first substrate 11 with the first electrode layer 12 on the surface and the second substrate 22 with the second electrode layer 21 on the surface: ITO / PET (purchased from Oike Industry Co., Ltd.);

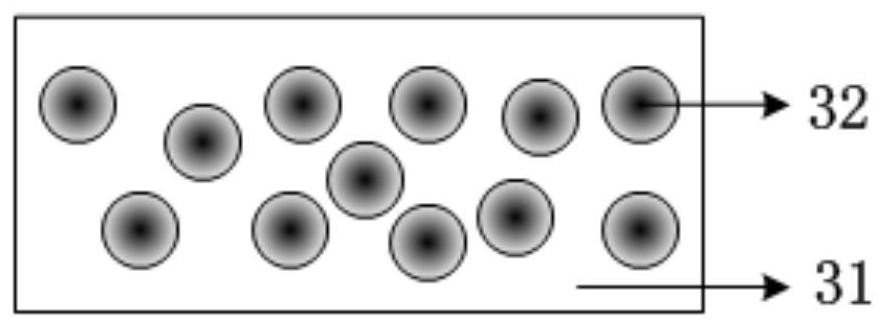

[0061] Electrochromic particles: tungsten oxide nanoparticles (purchased from Beijing Deke Daojin Technology Co., Ltd.), its basic performance indicators are content (%): 99.9, average particle size: 40nm, specific surface area: 30m 2 / g, particle shape: spherical;

[0062] Electrolyte: PVB+PC+LiClO 4 (available from Sigma-Aldrich);

[0063] Barrier layer: PMMA (purchased from Aladdin);

[0064] Filler particles: SiO 2 Particles (purchased from Beijing Deke Daojin Technology Co., Ltd.).

[0065] (2) Preparation of flexible electrochromic devices

[0066] A. Weigh tungsten oxide nanoparticles, LiClO 4 Add PC solution dropwise to tungsten oxide nanoparticles, insert electrodes (sheets or rods made of copper, stainless steel or aluminum), and e...

Embodiment 2

[0073] (1) Material:

[0074] The first substrate 11 with the first electrode layer 12 on the surface and the second substrate 22 with the second electrode layer 21 on the surface: ITO / PET (purchased from Oike Industry Co., Ltd.);

[0075] Barrier layer: ITO / PET / ITO (purchased from Oike Industry Co., Ltd.);

[0076] Electrochromic particles: tungsten oxide nanoparticles (purchased from Beijing Deke Daojin Technology Co., Ltd.), its basic performance indicators are content (%): 99.9, average particle size: 40nm, specific surface area: 30m 2 / g, particle shape: spherical;

[0077] Electrolyte: PVB+PC+LiClO 4 (available from Sigma-Aldrich);

[0078] Filler particles: montmorillonite particles and glass particles (purchased from Beijing Deke Daojin Technology Co., Ltd.).

[0079] (2) Preparation of flexible electrochromic devices

[0080] A. Weigh tungsten oxide nanoparticles, LiClO 4 Add PC solution dropwise to tungsten oxide nanoparticles, insert electrodes (sheets or rods...

Embodiment 3

[0087] Compared with Example 1, only the materials used in the first electrode layer and the second electrode layer in Example 1 were changed to silver nanowires, the material of the barrier layer was changed to PVB, and other materials were the same.

[0088] (2) Preparation of flexible electrochromic devices

[0089] The preparation process is exactly the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com