Environment-friendly indoor wall finishing method

A kind of green environmental protection, inner wall technology, applied in separation methods, chemical instruments and methods, construction, etc., to achieve the effect of enhanced performance, enhanced strength, and not easy to corrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

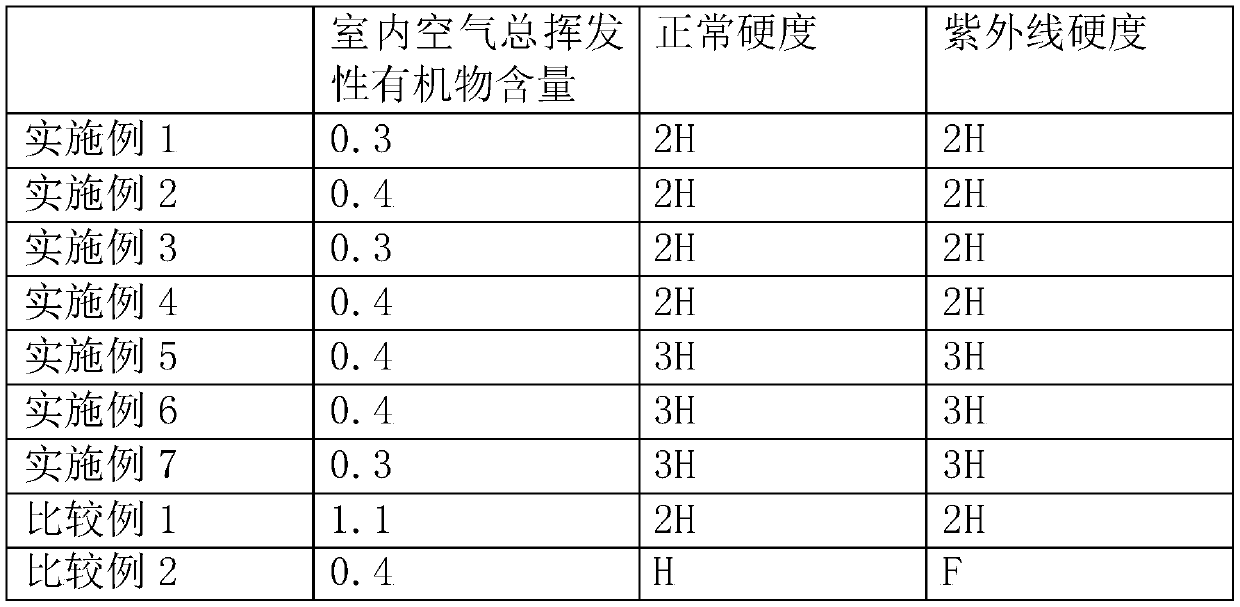

Examples

Embodiment 1

[0055] A green environmental protection indoor wall decoration method, comprising the following steps:

[0056] S1, prepare green environmental protection paint, specifically as follows:

[0057] Add 70kg of cement into a 200L stirring tank, stir at a speed of 180r / min, add 8kg of nano-microporous active silicon, 0.1kg of silane coupling agent, 50kg of calcium carbonate, and 8kg of salicylic acid while stirring, and mix well , to get green paint;

[0058] S2, evenly painting the green paint prepared by S1 on the outer surface of the wall;

[0059] S3. Scraping the green paint so that the surface of the green paint is even and the thickness of the green paint is uniform, and finally it is dried naturally to form a green paint.

Embodiment 2

[0061] A green environmental protection indoor wall decoration method, comprising the following steps:

[0062] S1, prepare green environmental protection paint, specifically as follows:

[0063] Add 75kg of cement into a 200L stirring tank, stir at a speed of 180r / min, add 9kg of nano-microporous active silicon, 0.3kg of silane coupling agent, 60kg of calcium carbonate, and 9kg of salicylic acid while stirring, and mix well , to get green paint;

[0064] S2, evenly painting the green paint prepared by S1 on the outer surface of the wall;

[0065] S3. Scraping the green paint so that the surface of the green paint is even and the thickness of the green paint is uniform, and finally it is dried naturally to form a green paint.

Embodiment 3

[0067] A green environmental protection indoor wall decoration method, comprising the following steps:

[0068] S1, prepare green environmental protection paint, specifically as follows:

[0069] Add 80kg of cement into a 200L stirring tank, stir at a speed of 180r / min, add 10kg of nano-microporous active silicon, 0.5kg of silane coupling agent, 70kg of calcium carbonate, and 10kg of salicylic acid while stirring, and mix well , to get green paint;

[0070] S2, evenly painting the green paint prepared by S1 on the outer surface of the wall;

[0071] S3. Scraping the green paint so that the surface of the green paint is even and the thickness of the green paint is uniform, and finally it is dried naturally to form a green paint.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com