Method using magnalium hydrotalcite to carry out deep desilication on sodium aluminate solution containing silicon

A technology of magnesium aluminum hydrotalcite and sodium aluminate, applied in chemical instruments and methods, alumina/aluminum hydroxide, aluminum compounds, etc., can solve problems such as biological environmental pollution, polluted offshore seawater, and difficult treatment of bauxite. Achieve the effect of improving the environment, reducing production costs, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

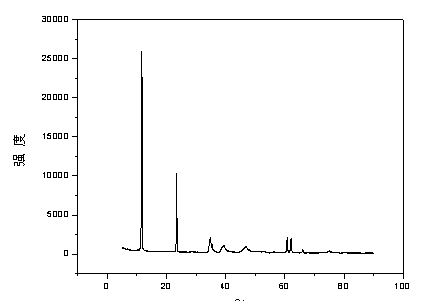

Image

Examples

Embodiment 1

[0033] (1) Naturally evaporate, concentrate, and crystallize the brine, filter to remove impurities and crystals, obtain refined brine containing magnesium chloride, and adjust it with water to make the concentration of magnesium chloride 0.5mol / L, and add a certain amount of aluminum chloride at the same time, Make Mg2+ with Al 3+ The molar ratio is 3, dubbed salt solution A.

[0034] (2) Dissolve sodium hydroxide in water to make its concentration 1mol / L, add a certain amount of sodium carbonate at the same time, and make the molar ratio NaOH / (NaOH+Na 2 CO 3 ) is 0.8,, dubbed alkaline solution B.

[0035] (3) 300ml of solution B prepared in step (2) is added in the reaction tank with jacket, in the jacket of the reaction tank with jacket, pass into circulating oil bath, the temperature of solution B is adjusted to 30 ℃, under the stirring speed of 200rpm, 300ml of solution A prepared in step (1) is added in the reaction tank, the control reaction temperature is 30 ℃, the ...

Embodiment 2

[0043] Add the dry magnesium aluminum hydrotalcite obtained in Example 1 into the silicon-containing sodium aluminate solution, wherein the magnesium aluminum hydrotalcite is added in an amount of 50 g / L; the desiliconization temperature is 130°C for 600 minutes ; approximately 81% SiO in a silicon-containing sodium aluminate solution 2 Removed from the silicon-containing sodium aluminate solution, the silicon content index of the desiliconized sodium aluminate solution is about 105;

[0044] The composition of described silicon-containing sodium aluminate solution:

[0045] Calculated by NaOH, the concentration of caustic soda is 500g / L;

[0046] Press Al 2 o 3 The concentration of alumina is 200g / L;

[0047] by SiO 2 Calculated, the concentration of silicon is 10g / L.

Embodiment 3

[0049] (1) Naturally evaporate, concentrate, and crystallize the brine, filter to remove impurities and crystals, obtain refined brine containing magnesium chloride, and adjust it with water to make the concentration of magnesium chloride 0.5mol / L, and add a certain amount of aluminum chloride at the same time, Make Mg 2+ with Al 3+ The molar ratio is 3, dubbed salt solution A.

[0050] (2) Dissolve sodium hydroxide in water to make its concentration 1mol / L, add a certain amount of sodium carbonate at the same time, and make the molar ratio NaOH / (NaOH+Na 2 CO 3 ) is 0.8,, dubbed alkaline solution B.

[0051] (3) 300ml of solution B prepared in the step (2) is added in the reaction tank with jacket, and the circulating oil bath is passed into the jacket of the reaction tank with jacket, and the temperature of solution B is adjusted to 80 ℃, under the stirring speed of 200rpm, 300ml of solution A prepared in step (1) is added in the reaction tank, the control reaction temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com