A kind of preparation method of boropolysilicate aluminum iron-chitosan composite flocculant

A technology of polyaluminum-iron-silicate and composite flocculants, which is applied in the fields of chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc. Large dosage and other problems, to achieve the effect of environmental protection in the preparation process, good flocculation effect, and strong adsorption characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

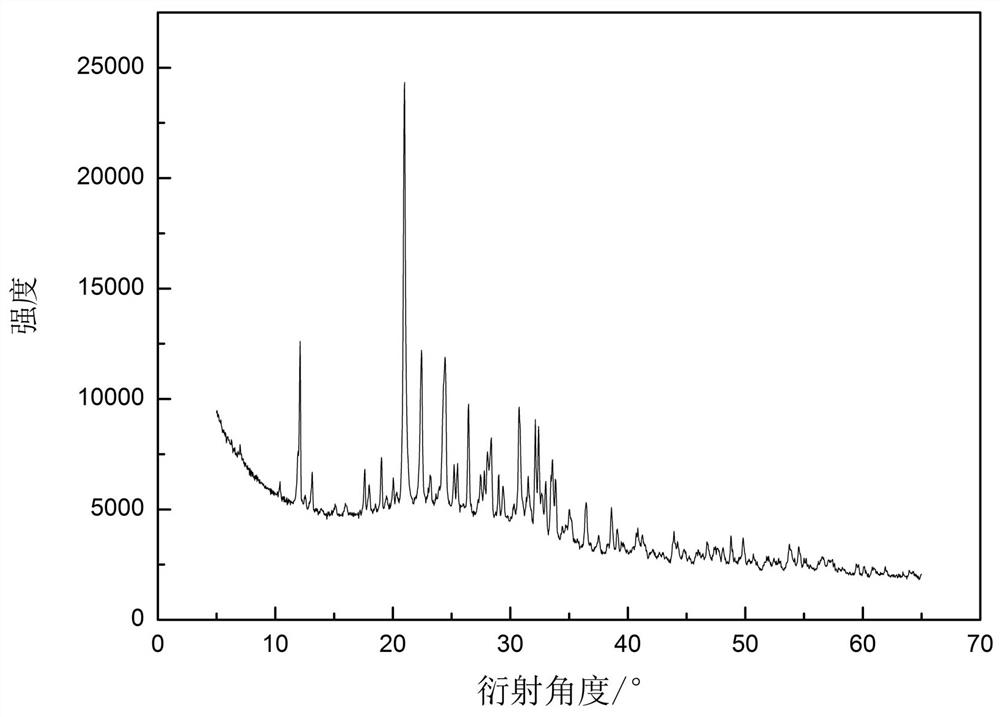

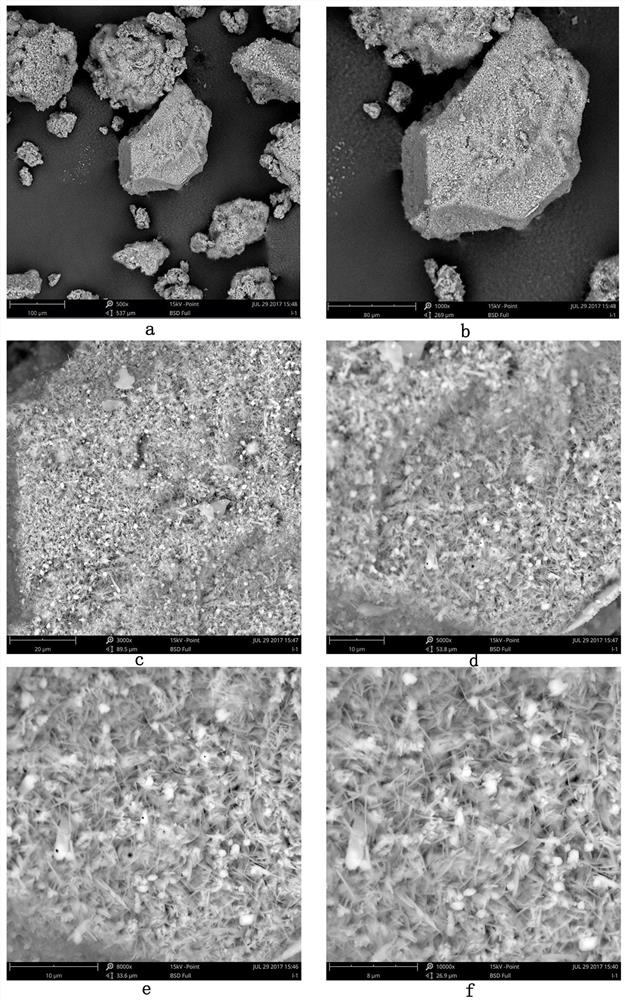

[0026] The borosilicate aluminum iron-chitosan composite flocculant involved in the present invention is prepared from aluminum sulfate, iron sulfate, sodium silicate, sodium tetraborate and chitosan as raw materials, and the specific preparation method comprises the following steps:

[0027] 1) Preparation of polysilicic acid: Add a sodium silicate solution with a concentration of 0.5mol / L to a sulfuric acid solution with a volume fraction of 50%, adjust the pH=3~3.5, stir at 30°C, and polymerize for 30~40min. Transparent light blue, made of polysilicic acid;

Embodiment 1

[0031] (1) Prepare 0.5mol / L sodium silicate solution, add it to sulfuric acid solution with a volume fraction of 50%, adjust pH=3.0, stir at 30°C and 500r / min, and the solution will be transparent and light blue after polymerization for 30 minutes. Prepare polysilicic acid solution;

[0032] (2) Add 0.5mol / L aluminum sulfate, 0.5mol / L ferric sulfate, 0.1mol / L sodium tetraborate and 10g / L chitosan acetic acid solution, adjust the pH with a 50% sulfuric acid solution to make the pH = 1.5, stir at 30°C and 500r / min for 1h, After static aging for 1 day, the composite flocculant of iron aluminum borosilicate-chitosan was prepared.

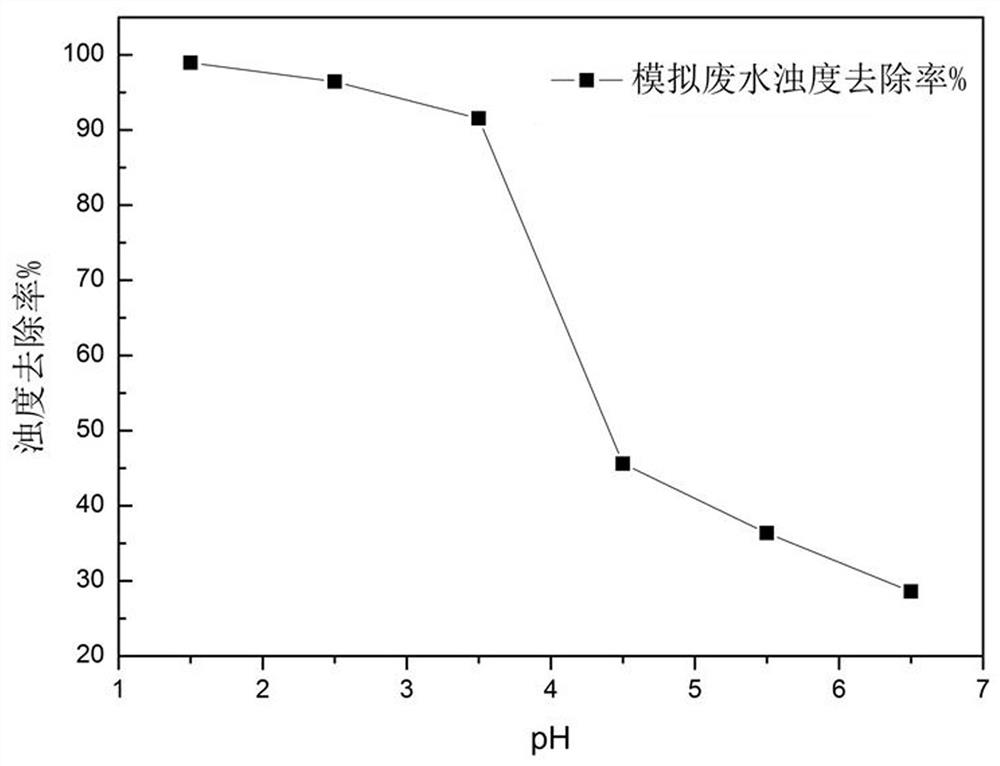

[0033] Add 0.5mL flocculant to 500mL kaolin simulated wastewater, first stir at 300r / min for 2min, then stir at 100r / min for 8min, let stand for 15min and take the supernatant to measure the turbidity removal rate, the turbidity removal rate is 99.01% .

Embodiment 2

[0035] The preparation process is the same as in Example 1, except that chitosan / Si (mass ratio)=0.08.

[0036] Add 0.5mL flocculant to 500mL kaolin simulated wastewater, first stir at 300r / min for 2min, then stir at 100r / min for 8min, let stand for 15min and take the supernatant to measure the turbidity removal rate, the turbidity removal rate is 99.26% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com