Method for removing heavy metal ions from wastewater of thermal power plant

A technology of heavy metal ions and thermal power plants, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as complex process routes and unstable operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

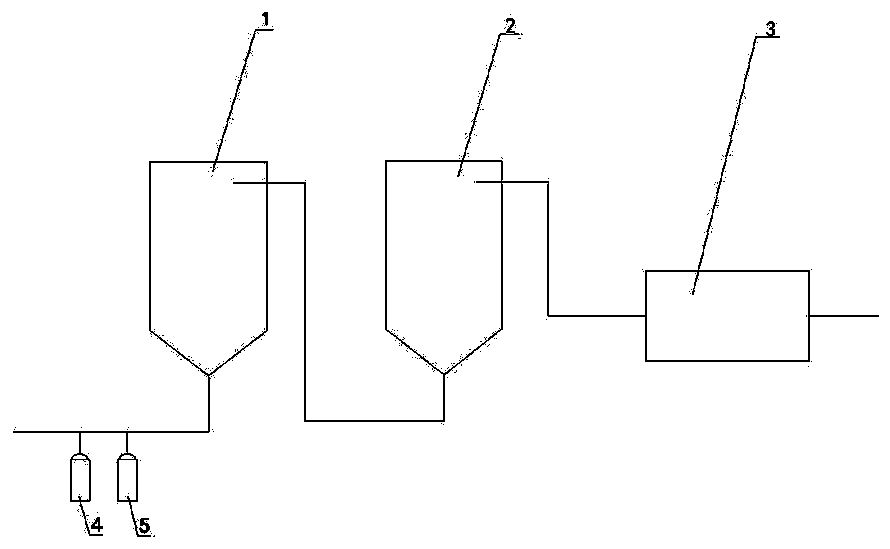

[0016] A method for removing heavy metal ions from thermal power plant wastewater, which is applied to desulfurization wastewater before it enters recycling treatment, and its specific steps are as follows:

[0017] (1) Desulfurization waste water enters the first fluidized bed 1 from the bottom, wherein the quartz sand filter material is filled in the first fluidized bed 1, and NaOH solution tank 5 and KMnO solution tank 4 are connected at the bottom of the first fluidized bed 1 , while desulfurization wastewater enters the first fluidized bed 1 from the bottom, NaOH solution, KMnO 4 The solution enters the first fluidized bed 1 together from the bottom of the first fluidized bed 1; the pH in the first fluidized bed 1 is controlled between 7.5 and 11 by controlling the addition of NaOH solution; Heavy metal ions such as Cd and Zn are removed for the first time;

[0018] (2) The desulfurization waste water after the step (1) treatment enters the second fluidized bed 2; by con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com