Antibacterial durable PE composite particle

A kind of composite particle and durable technology, which is applied in the direction of filter screen, grid, solid separation, etc., can solve the problems of poor antibacterial durability, inconvenient replacement and cleaning of particle screening filter, and low service life, so as to achieve good anti-aging, good anti-corrosion UV performance, impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] An antibacterial and durable PE composite particle, the PE composite particle is prepared from the following raw materials in parts by weight: 30 parts of waste plastics, 5 parts of nano-modified bamboo charcoal powder, 0.1 part of No. 10 white oil, 2 parts of polyethylene wax, silane di 0.1 parts of joint agent and 20 parts of PE resin:

[0039] The PE composite particles are prepared through the following steps:

[0040] Step 1. Weigh the above raw materials, then add 5 parts of nano-modified bamboo charcoal powder, 0.1 part of No. 10 white oil, 2 parts of polyethylene wax, 0.1 part of silane coupling agent and 20 parts of PE resin into a high-speed mixer and mix them. Nano-modified bamboo charcoal plastic particles are obtained by extruding and granulating with a twin-screw extruder;

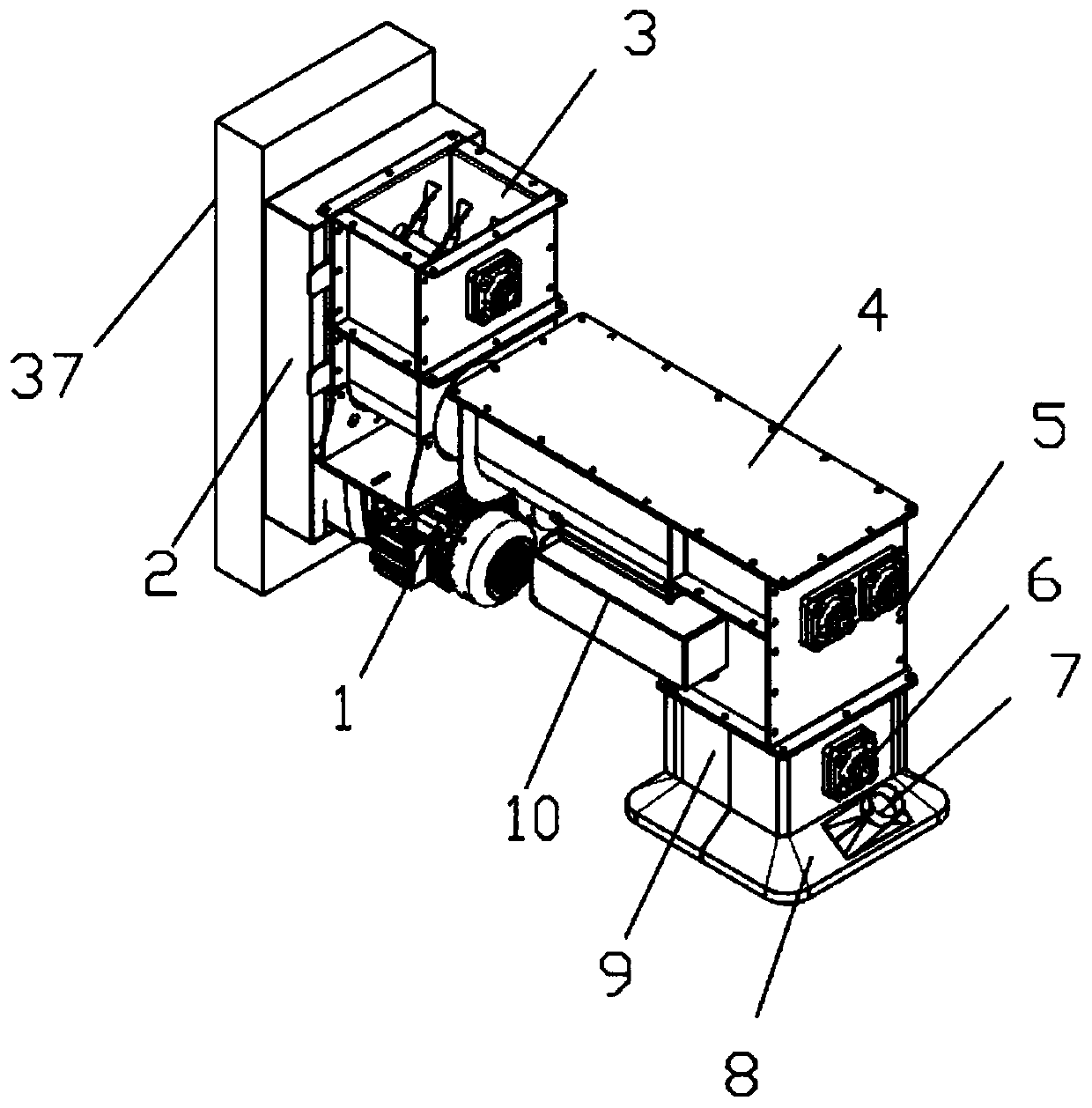

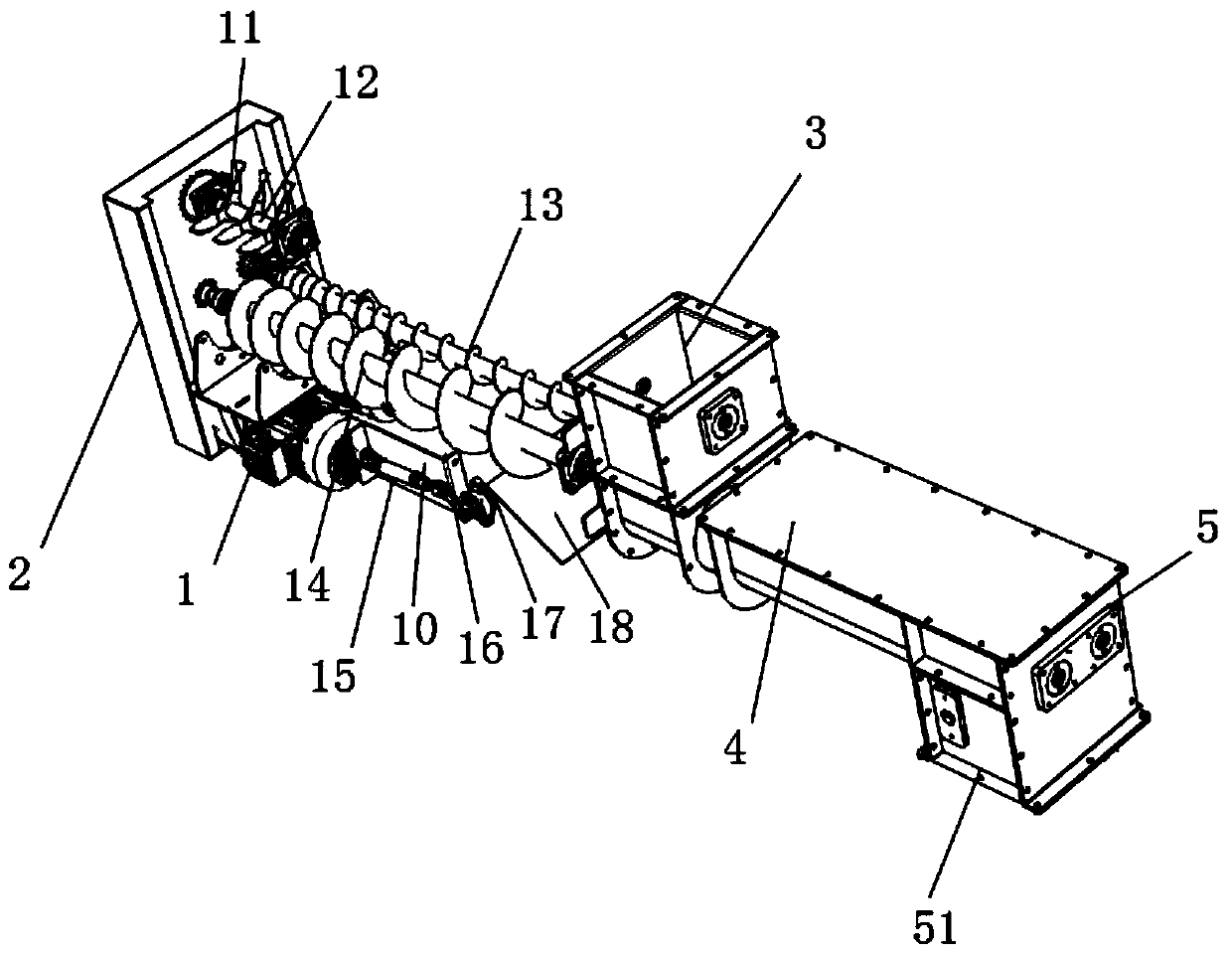

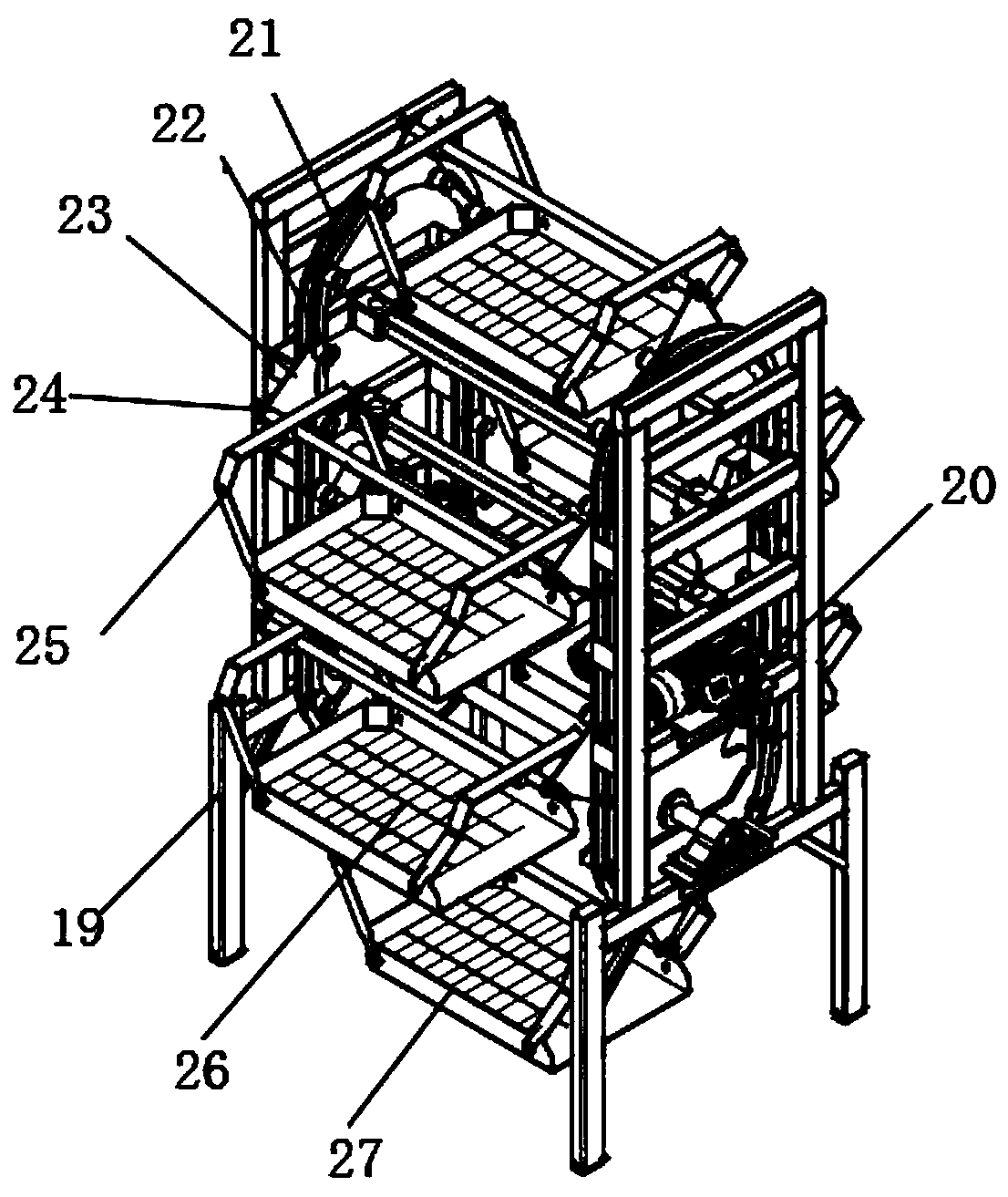

[0041] Step 2: Add 30 parts of waste plastics into the feeding box 3 of the conveying mechanism, drive the drive motor 1, drive the screw one 13, the screw two 14 and the crushing rod...

Embodiment 2

[0050] An antibacterial and durable PE composite particle, the PE composite particle is prepared from the following raw materials in parts by weight: 40 parts of waste plastics, 5 parts of nano-modified bamboo charcoal powder, 5 parts of No. 10 white oil, 8 parts of polyethylene wax, silane di 5 parts of joint agent and 40 parts of PE resin:

[0051] The PE composite particles are prepared through the following steps:

[0052] Step 1. Weigh the above raw materials, then add 5 parts of nano-modified bamboo charcoal powder, 5 parts of No. 10 white oil, 8 parts of polyethylene wax, 5 parts of silane coupling agent and 40 parts of PE resin into a high-speed mixer and mix them. Nano-modified bamboo charcoal plastic particles are obtained by extruding and granulating with a twin-screw extruder;

[0053] Step 2: Add 40 parts of waste plastics into the feeding box 3 of the conveying mechanism, drive the drive motor 1, drive the screw one 13, the screw two 14 and the crushing rod 12 t...

Embodiment 3

[0060] An antibacterial and durable PE composite particle, the PE composite particle is prepared from the following raw materials in parts by weight: 35 parts of waste plastics, 5 parts of nano-modified bamboo charcoal powder, 3 parts of No. 10 white oil, 5 parts of polyethylene wax, silane di 3 parts of joint agent and 30 parts of PE resin:

[0061] The PE composite particles are prepared through the following steps:

[0062] Step 1. Weigh the above raw materials, then add 5 parts of nano-modified bamboo charcoal powder, 3 parts of No. 10 white oil, 5 parts of polyethylene wax, 3 parts of silane coupling agent and 30 parts of PE resin into a high-speed mixer and mix them. Nano-modified bamboo charcoal plastic particles are obtained by extruding and granulating with a twin-screw extruder;

[0063] Step 2: Add 35 parts of waste plastics into the feeding box 3 of the conveying mechanism, drive the drive motor 1, drive the screw one 13, the screw two 14 and the crushing rod 12 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com