Water purification type solid waste pervious concrete

A permeable concrete and water purification technology, applied in the field of building materials manufacturing, can solve problems affecting groundwater quality, destroying surface structures and surrounding environments, consuming natural resources, manpower and material resources, etc., achieving significant water purification characteristics, reducing mining and environmental pollution , Realize the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

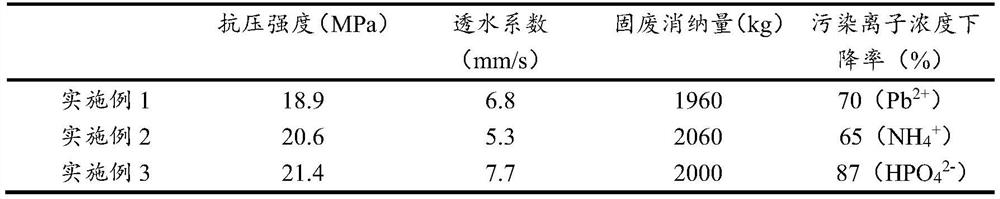

Embodiment 1

[0030] Choose S95 grade slag powder from Wuhan Ganghua Cement Plant, and the dosage is 300kg / m 3 ;Choose highly alkaline red mud from the red mud yard of Jianfeng Aluminum Industry in Yangquan, Shanxi, with a dosage of 60kg / m 3 The alkali activator selects the mixed solution of sodium hydroxide and sodium silicate for use, and the modulus M (SiO 2 / Na 2 O) is 1, and the consumption of alkali activator is 70kg / m 3 , the amount of water used must be miscible with the alkali activator at a water-cement ratio of 0.23; single-grain steel slag with a size of 4.75-9.5mm is selected from the aged and pre-wet steel slag as coarse aggregate, and the dosage is 1600kg / m 3 . According to the preparation method of conventional permeable concrete, the above materials are mixed with a concrete mixer for 60 seconds, then molded in three layers, and formed by pressing up and vibrating down. The size of the test mold is 100*100*100mm. After curing for 28 days, the product was obtained, and...

Embodiment 2

[0032] Select grade Ⅱ fly ash of Wuhan Yangluo Power Plant, the dosage is 340kg / m 3 ;Choose highly alkaline red mud from the red mud yard of Shanxi Yangquan Jianfeng Aluminum Industry, and the dosage is 70kg / m 3 The alkali activator selects sodium hydroxide and sodium silicate mixed solution for use, and the modulus M (SiO 2 / Na 2 O) is 0.8, the amount of alkali activator is 75kg / m 3 , the amount of water is guaranteed to be miscible with the alkali activator at a water-cement ratio of 0.21; single-grain steel slag with a size of 4.75-9.5mm is selected from the aged and pre-wet steel slag as coarse aggregate, and the dosage is 1650kg / m 3. According to the preparation method of conventional permeable concrete, the above materials are mixed with a concrete mixer for 60 seconds, then molded in three layers, and formed by pressing up and vibrating down. The size of the test mold is 100*100*100mm. The product was obtained after curing for 28 days, and its water permeability coe...

Embodiment 3

[0034] Select S95 grade slag powder from Datang Shandong Power Generation Co., Ltd., and the dosage is 320kg / m 3 ; Choose highly alkaline red mud from Jiangxi Hongcheng Aluminum Co., Ltd., with a dosage of 80kg / m 3 The alkali activator selects sodium hydroxide and sodium silicate mixed solution for use, and the modulus M (SiO 2 / Na 2 O) is 1, and the consumption of alkali activator is 80kg / m 3 , the amount of water is guaranteed to be miscible with the alkali activator at a water-cement ratio of 0.23; single-grained steel slag with a size of 9.5-13.2mm is selected from the aged and pre-wetted steel slag as coarse aggregate, and the dosage is 1600kg / m 3 . According to the preparation method of conventional permeable concrete, the above materials are mixed with a concrete mixer for 60 seconds, then molded in three layers, and formed by pressing up and vibrating down. The size of the test mold is 100*100*100mm. After curing for 28 days, the product was obtained, and its water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com