Succinic anhydride modified polymine grafting medium, preparation method and application thereof

The technology of polyethyleneimine and succinic anhydride is applied in the fields of succinic anhydride modified polyethyleneimine grafting medium and preparation, and protein chromatographic separation, and can solve the problems of reducing production cost, restricting the production of biological macromolecules, etc. The effect of good tolerance and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

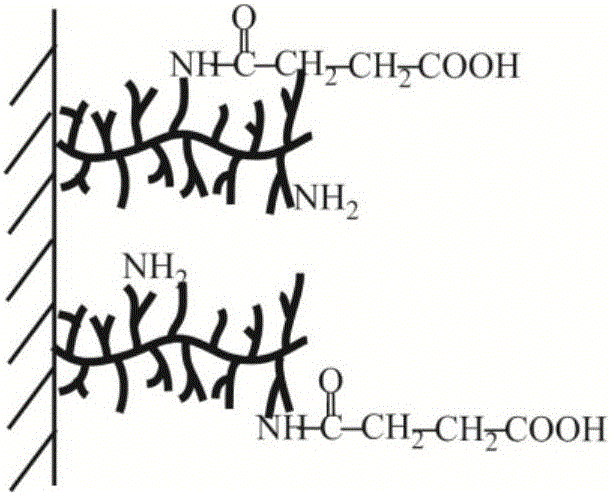

[0027] 1) Introduce polyethyleneimine grafted chains on the surface of the agarose gel through the epoxy-based spacer arm, and then take 5 g of polyethyleneimine grafted media with an ion exchange capacity of 740 mmol / L and use N,N-dimethyl formazan Amide soaking until the solvent in the well is completely replaced by N,N-dimethylformamide;

[0028] 2) Drain the medium obtained in step 1) with a G3 funnel and place it in a 50mL Erlenmeyer flask, then continue to add 20mL N,N-dimethylformamide into the Erlenmeyer flask, mix well, and prepare a medium suspension;

[0029] 3) Add 0.111g of succinic anhydride to the medium suspension obtained in step 2), mix well, place in a constant temperature water bath at 25°C, react at 170rpm for 24h, and then rinse with N,N-dimethylformamide, ethanol and water in sequence As a medium, a succinic anhydride-modified polyethyleneimine grafted medium with a carboxyl ion exchange capacity of 150 mmol / L was obtained.

Embodiment 2

[0031] The amount of succinic anhydride added in Example 1 was changed to 0.2294 g, and under other conditions unchanged, a succinic anhydride-modified polyethyleneimine grafted medium with a carboxyl ion exchange capacity of 240 mmol / L was obtained.

Embodiment 3

[0033] The amount of succinic anhydride added in Example 1 was changed to 0.296g, and under other conditions unchanged, a succinic anhydride-modified polyethyleneimine grafted medium with a carboxyl ion exchange capacity of 270mmol / L was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com