Clothing treatment barrel and clothing treatment device

A technology for clothes processing and buckets, which is applied in washing devices, other washing machines, textiles and paper making, etc., can solve the problems of increasing the production cost of clothes devices, increasing the economic burden of consumers, and not having wide applicability, so as to achieve good clothes processing Effect, improvement of clothing treatment effect, effect of reducing economic burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

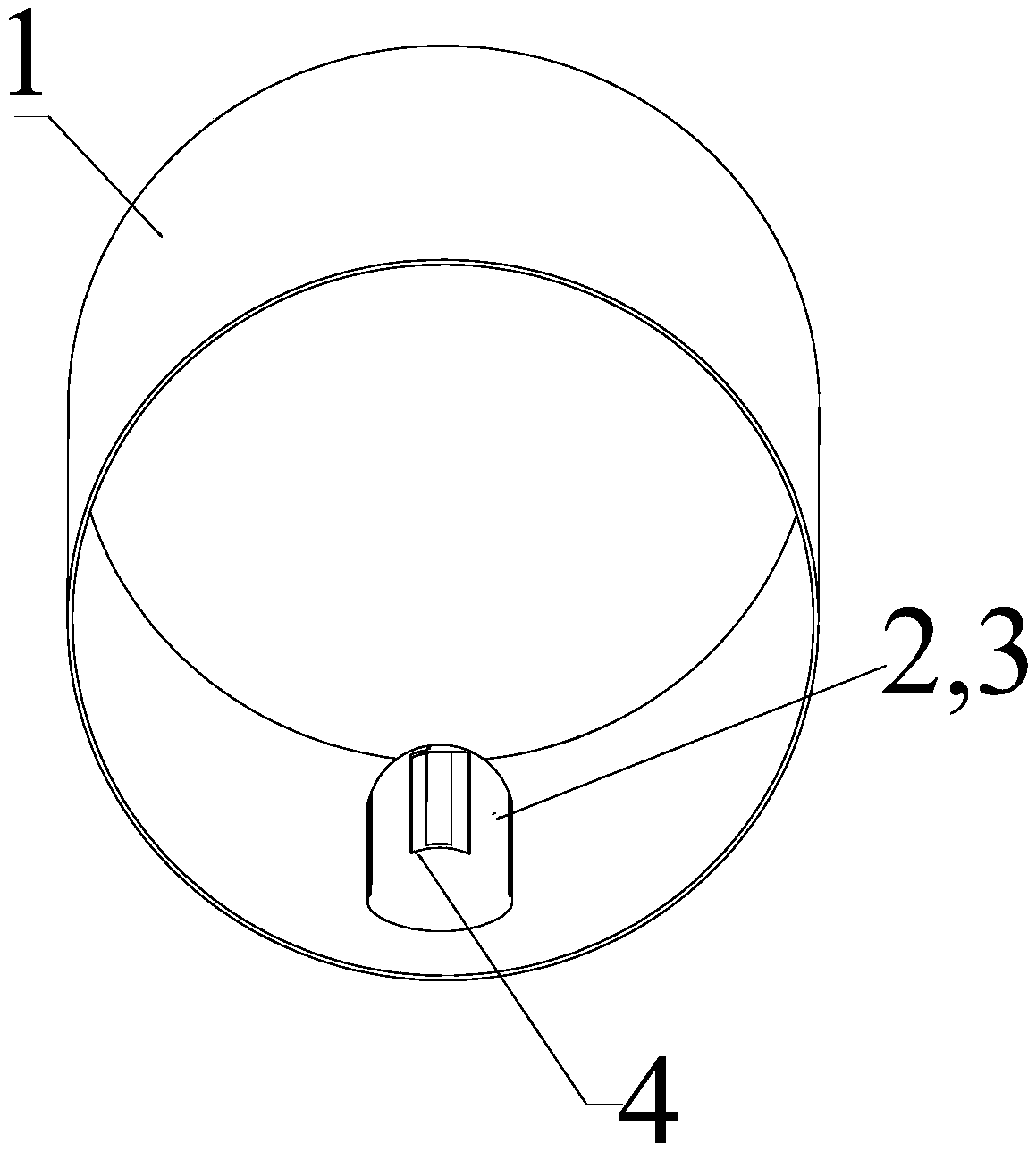

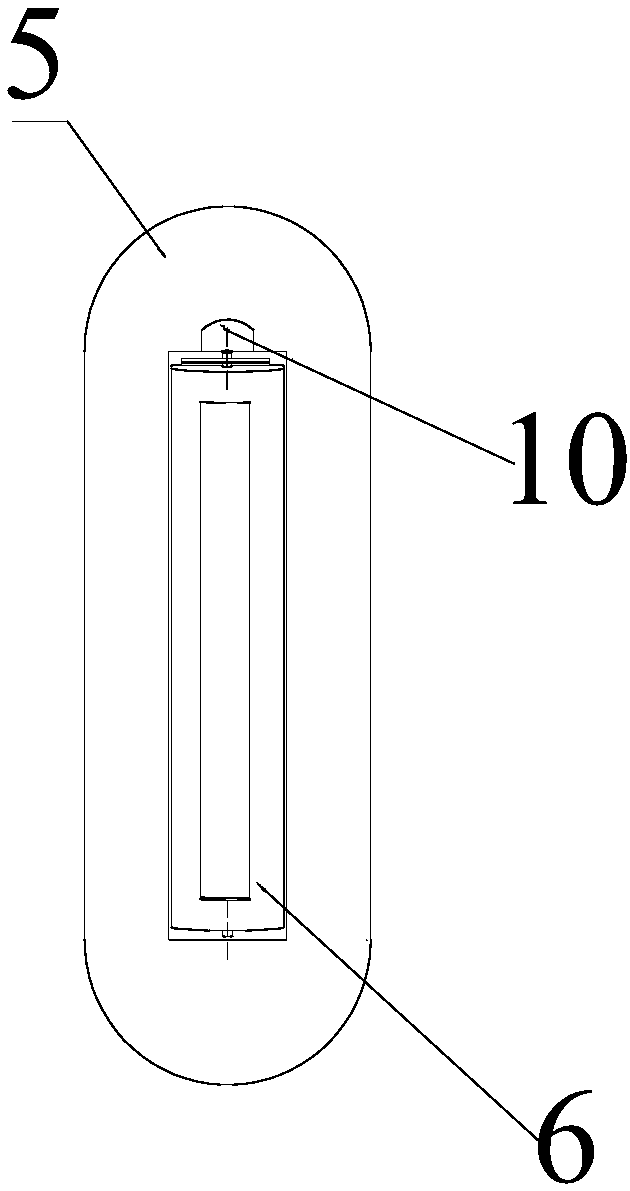

[0045] like Figure 1-5As shown, this embodiment provides a laundry treatment bucket 1, the wall of the laundry treatment bucket 1 is provided with an accommodating chamber 4 for placing a laundry treatment reagent 9, and the laundry treatment reagent 9 is released to the inside of the laundry treatment bucket 1, or The air and / or liquid in the laundry processing tub 1 enters into the accommodating chamber 4 .

[0046] The laundry processing tub 1 of this embodiment is a tub directly in contact with clothes, etc., and may be an inner tub of a washing machine, a drying tub of a clothes dryer, or an inner tub of an all-in-one washing and drying machine. The wall of the laundry treatment bucket 1 in this embodiment is provided with an accommodating chamber 4, and the laundry treatment reagent 9 is added in the accommodating chamber 4, and the laundry treatment reagent 9 can be used in the accommodating chamber 4 to treat the incoming air or The washing water is processed, or the...

Embodiment 2

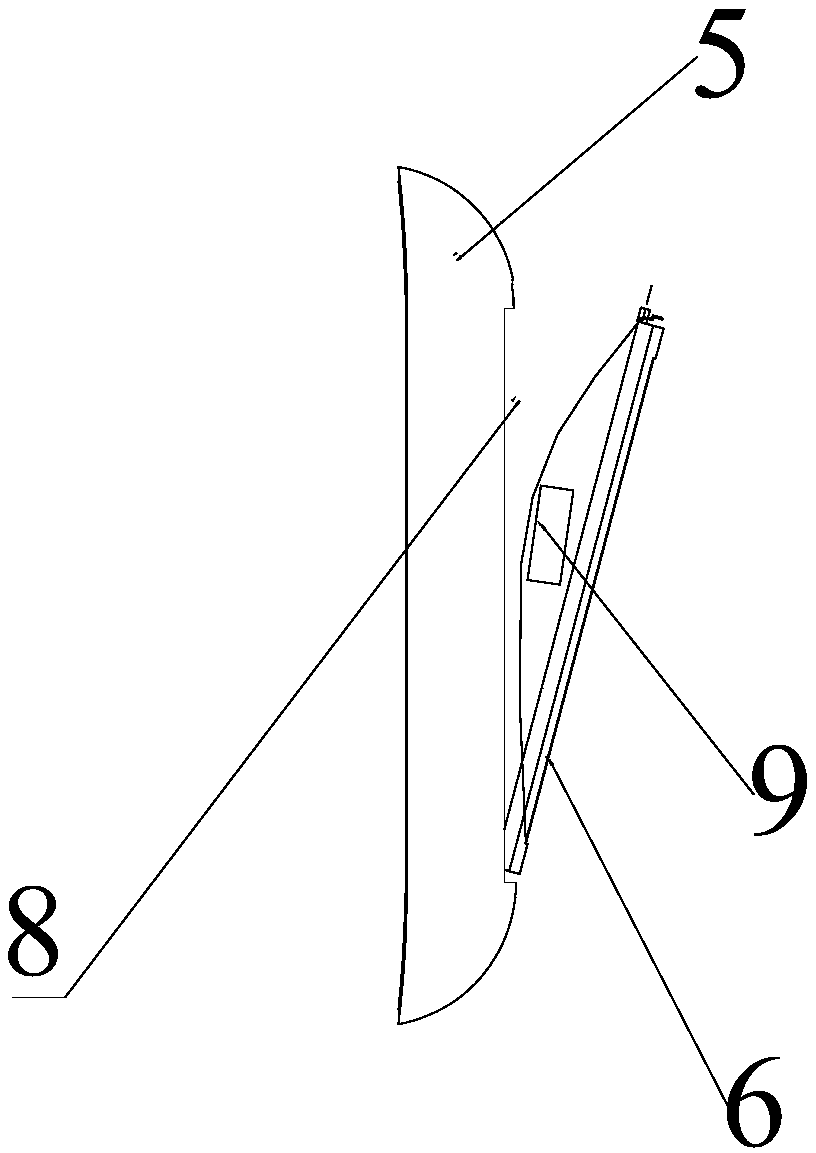

[0064] like Figure 1-5 As shown, this embodiment is a further limitation of Embodiment 1. In this embodiment, the laundry processing bucket 1 includes a bucket body and an additional structure 2 installed on the wall of the bucket body, and the additional structure 2 is installed on the inner wall of the bucket body The lifting structure 3 on the top, the lifting structure 3 protrudes inwardly relative to the inner wall of the bucket body, and extends upwards from the lower part of the bucket body, the water flow at the bottom of the laundry processing bucket 1 or the clothes climb up along the lifting structure 3 to the clothes The upper part of the barrel 1 is processed, and the accommodating chamber 4 is arranged in the lifting structure 3 .

[0065] In this embodiment, the additional structure 2 is a lifting structure 3, that is, a lifting rib. The interior of the existing laundry processing tub 1 is basically provided with a lifting structure 3 . The lifting structure ...

Embodiment 3

[0081] like Figure 5 As shown, this embodiment provides a laundry processing device, which includes a box body 11, and the laundry processing tub 1 as described in the first or second embodiment is installed in the box body 11.

[0082] The laundry processing device in this embodiment may be a washing machine, a clothes dryer, or an all-in-one washing and drying machine. The washing machine may be a wave-wheel washing machine, a drum washing machine, or a double-tub washing machine. No matter what kind of laundry treatment device, it has a box body 11, and a laundry treatment bucket 1 is arranged in the box body 11. An accommodating chamber 4 for placing a laundry treatment reagent 9 is arranged on the wall of the laundry treatment bucket 1. The air and / or liquid in the laundry processing tub 1 is released into the laundry processing tub 1 , or the air and / or liquid in the laundry processing tub 1 enters the accommodation chamber 4 .

[0083] Preferably, the inner wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com