External wall panel insulating coating and preparation method thereof

A technology for thermal insulation coatings and exterior wall panels, applied in coatings, anti-fouling/underwater coatings, paints containing biocides, etc., can solve the problems of accelerating coating cracking and pulverization, mold and algae, multiple steps in the production process, and hydrophobic Improve the mechanical strength and anti-washing performance, reduce the antibacterial and antifungal performance, and improve the tinting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

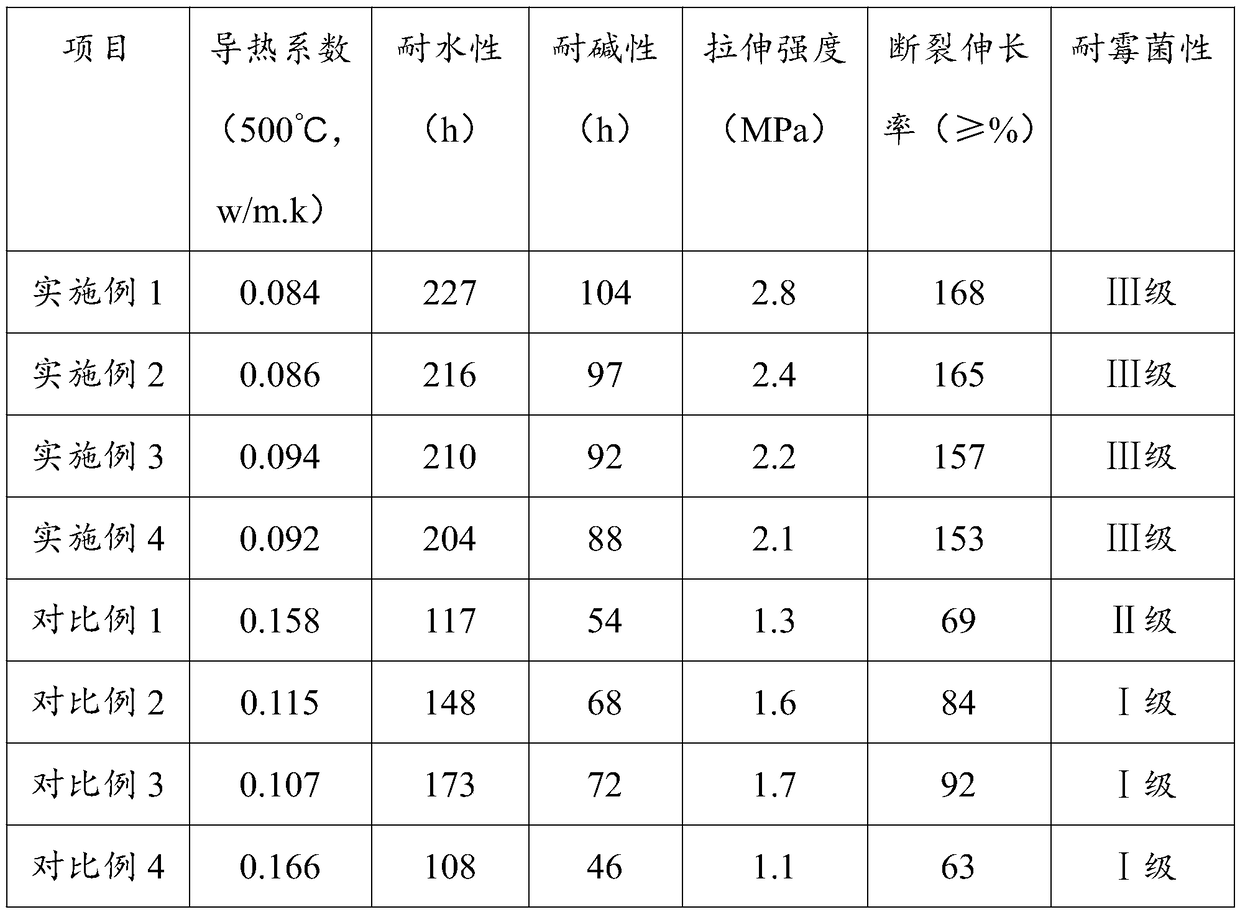

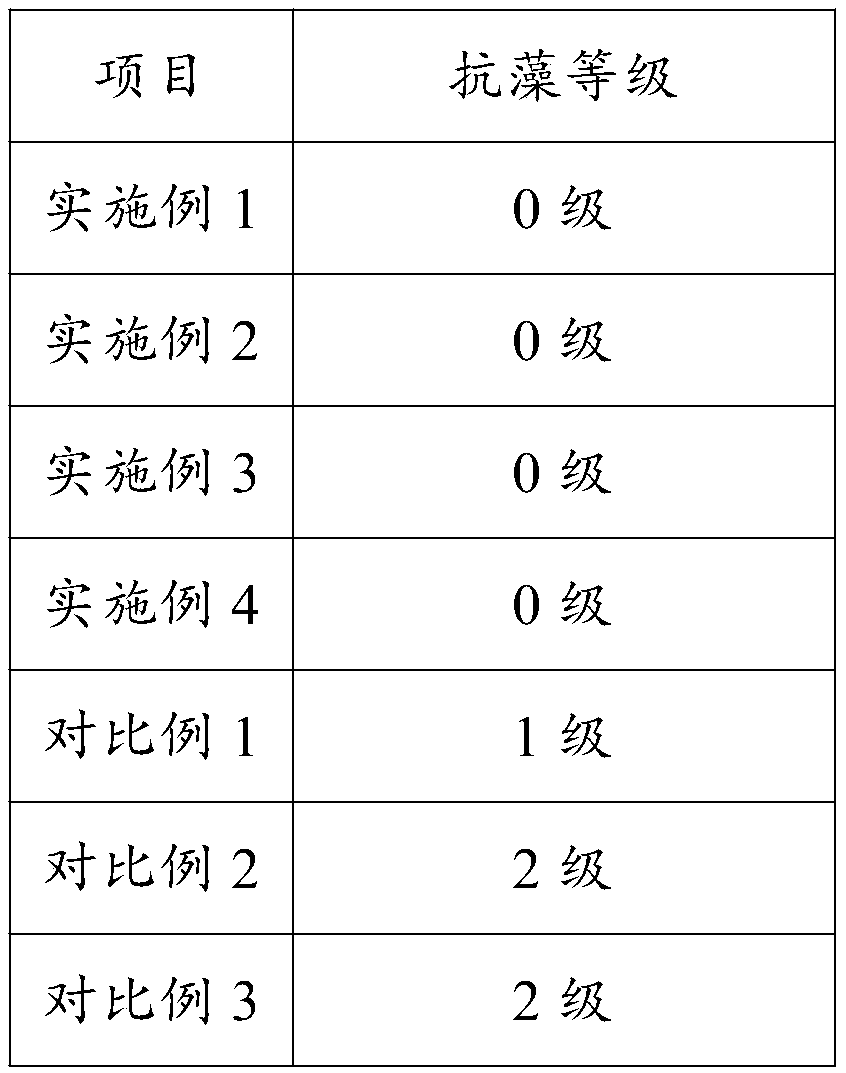

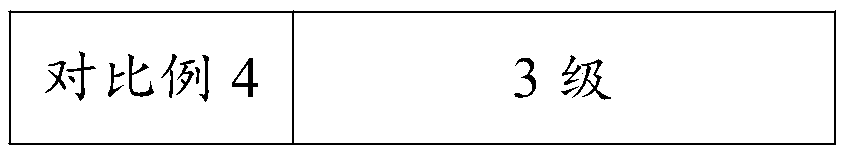

Examples

Embodiment 1

[0035] A thermal insulation coating for exterior wall panels, comprising the following components by weight: 116g of vinyl chloride / vinyl acetate / acrylate copolymer emulsion, 32g of silane coupling agent polymethyltrimethoxysiloxane, 13g of rutile titanium dioxide, ten 6g of dicarbonyl alcohol ester, 5g of modified bentonite, 4g of nano-antibacterial polymer microspheres, 0.5g of curing agent, 0.9g of anti-algae agent 1,2-benzisothiazolin-3-one, and 62g of tetrahydrofuran. Among them, the solid content of the vinyl chloride / vinyl acetate / acrylate copolymer emulsion is 46±2%, the viscosity is less than 100 Pa·s, and the glass transition temperature is 5°C. The curing agent is prepared by mixing diglycidyl ether, 650 low-molecular polyamide, and ultrafine reactive dicyandiamide according to the mass ratio of 1:0.6:0.4.

[0036] The preparation method of nano antibacterial polymer microsphere comprises the following steps:

[0037] 1) Add 30g of oil-soluble titanium dioxide to 1...

Embodiment 2

[0050] A thermal insulation coating for exterior wall panels, comprising the following components by weight: 122g of vinyl chloride / vinyl acetate / acrylate copolymer emulsion, 28g of silane coupling agent polymethylphenylsiloxane, 15g of rutile titanium dioxide, 12g Carbon alcohol ester 7g, modified bentonite 4g, nano antibacterial polymer microspheres 3g, curing agent 0.6g, anti-algae agent 4,5-dichloro-N-octyl-4-isothiazolin-3-one 0.9g, Tetrahydrofuran 65g. The solid content of the vinyl chloride / vinyl acetate / acrylate copolymer emulsion is 46±2%, the viscosity is less than 100 Pa·s, and the glass transition temperature is 5°C; the preparation method of the modified bentonite is the same as in Example 1. The curing agent is prepared by mixing diglycidyl ether, 650 low-molecular polyamide, and ultrafine reactive dicyandiamide according to the mass ratio of 1:0.6:0.4.

[0051] The preparation method of described nano antibacterial polymer microspheres comprises the following s...

Embodiment 3

[0058] A thermal insulation coating for exterior wall panels, comprising the following components by weight: 109g of vinyl chloride / vinyl acetate / acrylate copolymer emulsion, 27g of silane coupling agent polymethyltriethoxysiloxane, 10g of rutile titanium dioxide, 8g of dodecyl alcohol ester, 5g of modified bentonite, 4g of nano-antibacterial polymer microspheres, 0.6g of curing agent, 1.1g of anti-algae agent zinc pyrithione, and 66g of tetrahydrofuran. The solid content of vinyl chloride / vinyl acetate / acrylate copolymer emulsion is 46±2%, the viscosity is less than 100Pa·s, and the glass transition temperature is 5°C; the curing agent consists of diglycidyl ether, 650 low-molecular polyamide, ultrafine Active dicyandiamide is prepared by mixing according to the mass ratio of 1:0.6:0.4. The preparation method of modified bentonite is the same as in Example 1.

[0059] The preparation method of described nano antibacterial polymer microspheres comprises the following steps: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com