Washing agent for raw feather and preparation method thereof

A technology of detergent and raw wool, which is applied in the direction of detergent compounding agent, detergent composition, chemical instruments and methods, etc., can solve the problems of weak deodorization ability, decline in market competitiveness, single function, etc., and achieve improved deodorization and sterilizing ability, the effect of excellent washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] First heat 2.05kg of water to 60°C, then add 87kg of polyoxyethylene lauryl ether-7, 4kg of dipropylene glycol methyl ether, 5kg of secondary octanol, 0.5kg of methanol and 1kg of polyoxyethylene lauryl alcohol under constant stirring, and stir for 10 minutes Finally, add 0.2kg of sodium dodecylbenzenesulfonate, 0.2kg of tetrasodium edetate and 0.05kg of Cathone. After adding all of them, keep stirring for 1 hour to obtain the detergent.

Embodiment 2

[0016] First heat 2kg of water to 60°C, then add 86kg of polyoxyethylene lauryl ether-7, 4kg of dipropylene glycol methyl ether, 5kg of secondary octanol, 0.5kg of methanol and 1kg of polyoxyethylene lauryl alcohol under constant stirring, and stir for 10 minutes Add 0.2kg of sodium dodecylbenzenesulfonate, 0.2kg of tetrasodium edetate and 0.05kg of kason, keep stirring for 1 hour after adding all of them, and finally cool to room temperature, add 1kg of traditional Chinese medicine additives, mix well and get ready detergent.

Embodiment 3

[0018] First heat 2kg of water to 60°C, then add 87kg of polyoxyethylene lauryl ether-7, 5kg of dipropylene glycol methyl ether, 6kg of secondary octanol, 0.4kg of methanol and 1.5kg of polyoxyethylene lauryl alcohol under constant stirring, and stir for 10 minutes Finally, add 0.25kg sodium dodecylbenzenesulfonate, 0.15kg tetrasodium edetate and 0.08kg Cathone, keep stirring for 1 hour after adding all of them, and finally cool to room temperature, add 1kg of Chinese medicine additives, mix well and serve Get detergent.

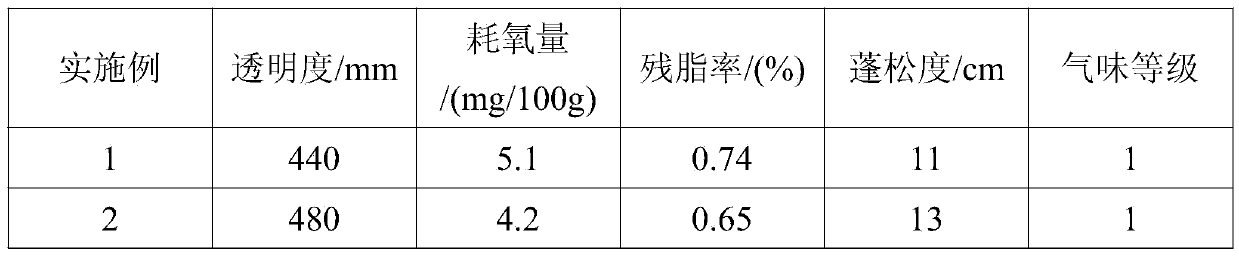

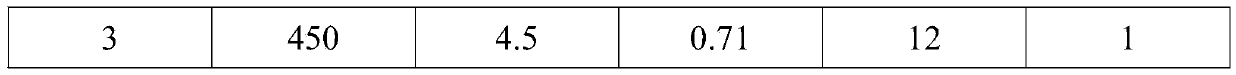

[0019] The detergent prepared in Examples 1-3 is washed with a bath ratio of 1:40 and a detergent concentration of 0.1% to white goose feathers, shaken and washed at room temperature for 30 minutes, rinsed 5 times, and tested for its washing effect after drying (according to GB / T10288-2003 down and feather test method) results are shown in Table 1:

[0020] Table 1 embodiment 1-3 detergent is to white goose feather washing effect

[0021]

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com