Breathable resin with high breathability and preparation method of breathable resin

A breathable and resin technology, applied in the field of breathable resin and its preparation, can solve the problems of short continuous production time, uneven distribution of calcium carbonate, poor air permeability, etc., and achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

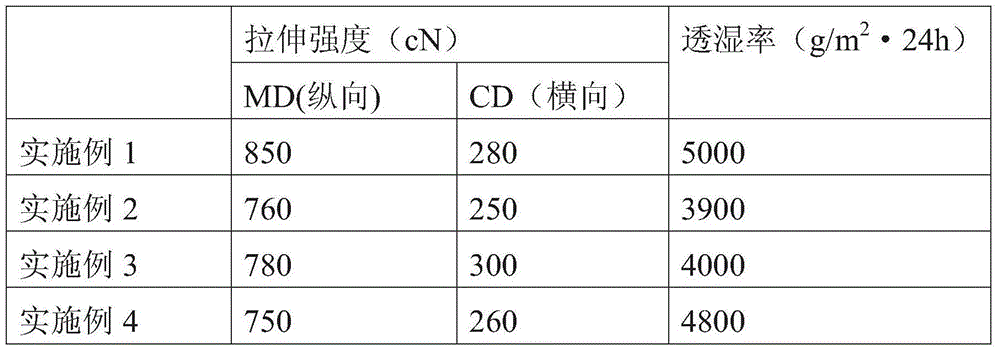

Examples

Embodiment 1

[0032] A breathable resin with high air permeability, which is made of the following components according to the weight percentage shown: calcium carbonate powder: 55%, antioxidant: 0.2%, processing aid: 0.5%, color masterbatch: 5%, 2036P polyethylene: 20%, 0271 polyethylene: 5%, metallocene 3518: 14.3%.

[0033] Wherein, antioxidant is antioxidant 168, and processing aid is silane coupling agent kh550 and lubricant, and the weight ratio of silane coupling agent kh550 and lubricant is 1:1.

[0034] A method for preparing a breathable resin with high gas permeability, the method comprising the steps of:

[0035] (1) The activation treatment of calcium carbonate powder, the steps are as follows:

[0036] a, 400 mesh calcium carbonate powder is mixed with the suspension liquid that mass percent concentration is 30~40%, add sodium stearate dispersant, sodium stearate add-on is 0.1wt% of calcium carbonate powder weight, carry out wet Grinding to a D50 average particle size of 1.8...

Embodiment 2

[0041]A breathable resin with high air permeability, which is made of the following components according to the weight percentage shown: calcium carbonate powder: 35%, antioxidant: 0.5%, processing aid: 2%, color masterbatch: 10%, 1048P polyethylene: 27.5%, 2426F polyethylene: 20%, metallocene SP330: 5%.

[0042] Among them, the antioxidant is 1010, the processing aid is titanate coupling agent 201 and lubricant, and the weight ratio of titanate coupling agent 201 and lubricant is 1:1.

[0043] A method for preparing a breathable resin with high gas permeability, the method comprising the steps of:

[0044] (1) The activation treatment of calcium carbonate powder, the steps are as follows:

[0045] a, 400 mesh calcium carbonate powder is mixed with the suspension liquid that mass percent concentration is 30~40%, adds sodium stearate dispersant, and sodium stearate add-on is 0.5wt% of calcium carbonate powder weight, carries out wet Grinding to D50 average particle size is 1....

Embodiment 3

[0050] A breathable resin with high air permeability, which is made of the following components by weight percentage: calcium carbonate powder: 39.3%, antioxidant: 0.2%, processing aid: 0.5%, color masterbatch: 5%, 1048P polyethylene: 30%, 2426F polyethylene: 20%, metallocene 3518: 5%.

[0051] Among them, antioxidant 1010 and antioxidant 168 are 50% each, processing aids are titanate coupling agent 401 and lubricant, and the weight ratio of titanate coupling agent 401 and lubricant is 1:1.

[0052] The preparation method is the same as in Example 1, only the content of each component is changed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com