Method for adjusting morphology and size of tungsten oxide by using carbon nanotube

A carbon nanotube and tungsten oxide technology, applied in the direction of tungsten oxide/tungsten hydroxide, nanotechnology, nanotechnology, etc., can solve the problem of less nanomaterials with different morphologies, and achieve easy availability of raw materials, wide application prospects, and preparation technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

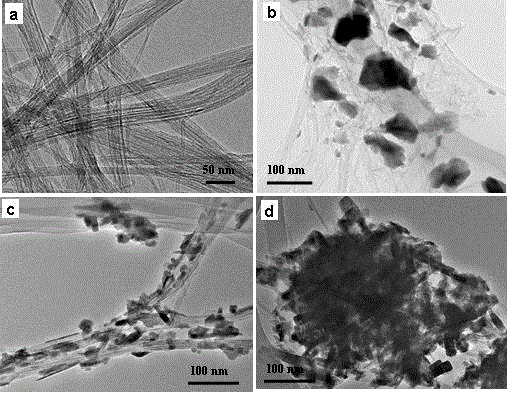

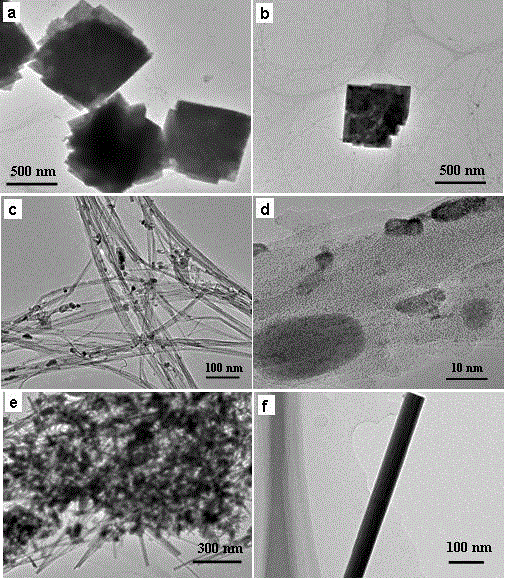

[0023] Soak 15 mg of carbon nanotubes with a diameter of 10nm and 3 layers in hydrochloric acid, reflux at 140°C under constant temperature stirring, filter, dry, and then disperse in 150mL ethylene glycol ultrasonically for 15 hours to obtain uniformly dispersed carbon nanotubes Ethylene glycol suspension; completely dissolve sodium tungstate in a mixture of deionized water and ethylene glycol to obtain a sodium tungstate solution with a concentration of 0.05 mol / L, wherein the molar ratio of sodium tungstate to carbon nanotubes is 2:1; add the carbon nanotube ethylene glycol suspension in step (1) to the sodium tungstate solution in step (2), stir it with a thermostatic magnetic stirrer under oil bath conditions, and mix it Mix well, use a micro-injector to add an appropriate amount of hydrochloric acid solution to the system when the oil bath temperature is 60°C. The hydrochloric acid concentration is 6mol / L, the dosage is 4mL, and the pH of the system is adjusted to 3; then ...

Embodiment 2

[0025] Soak 15mg of carbon nanotubes with a diameter of 20nm and 3 layers in nitric acid, reflux at 100°C under constant temperature stirring, filter, dry, and then place in 100mL ethylene glycol, and ultrasonically disperse for 8h to obtain uniformly dispersed carbon nanotubes Tube ethylene glycol suspension; completely dissolve sodium tungstate in deionized water to obtain a sodium tungstate solution with a concentration of 0.05 mol / L; the molar ratio of sodium tungstate to carbon nanotubes is 6:1. Add the carbon nanotube ethylene glycol suspension in step (1) to the sodium tungstate solution in step (2), stir it with a constant temperature magnetic stirrer under oil bath conditions, and mix them evenly. When the oil bath temperature is 60℃, use a micro-injector to add a proper amount of hydrochloric acid solution to the system. The concentration of hydrochloric acid is 8mol / L, the dosage is 4mL, and the pH of the system is adjusted to 1-5; then the reaction temperature is inc...

Embodiment 3

[0027] Soak 15 mg of carbon nanotubes with a diameter of 20 nm and 3 layers in a mixture of hydrochloric acid and nitric acid. In the medium, reflux under constant temperature stirring at 120°C, filter and dry, and then place it in 100 mL of ethylene glycol for ultrasonic dispersion for 12 hours to obtain a uniformly dispersed carbon nanotube ethylene glycol suspension; completely dissolve the sodium tungstate in deionized water and In the mixture of ethylene glycol, a sodium tungstate solution with a concentration of 0.05 mol / L is obtained; the molar ratio of sodium tungstate to carbon nanotubes is 8:1. Add the carbon nanotube ethylene glycol suspension in step (1) to the sodium tungstate solution in step (2), stir it with a constant temperature magnetic stirrer under oil bath conditions, and mix them evenly. When the oil bath temperature is 70℃, use the micro-injector to add an appropriate amount of hydrochloric acid solution to the system. The concentration of hydrochloric a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com