Graphene electric-conduction ink preparation method, graphene electric-conduction ink film and graphene electric-conduction ink film composite material film

A technology of composite film and conductive ink, which is applied in the field of preparation of graphene conductive ink composite film, graphene conductive ink film, and graphene conductive ink, can solve the problems of hindering graphene, high toxicity, narrow application range, etc. Achieve the effects of environmental protection in the production process, wide viscosity and fineness, and wide adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0034] Further illustrate the present invention by the following examples, do not limit the present invention in any way, under the premise of not departing from the technical solution of the present invention, any modification or change that those of ordinary skill in the art that the present invention is done to implement easily will all be fall within the scope of the claims of the present invention.

[0035] The invention provides a kind of preparation method of graphene conductive ink, and it comprises following specific embodiment:

Embodiment 1

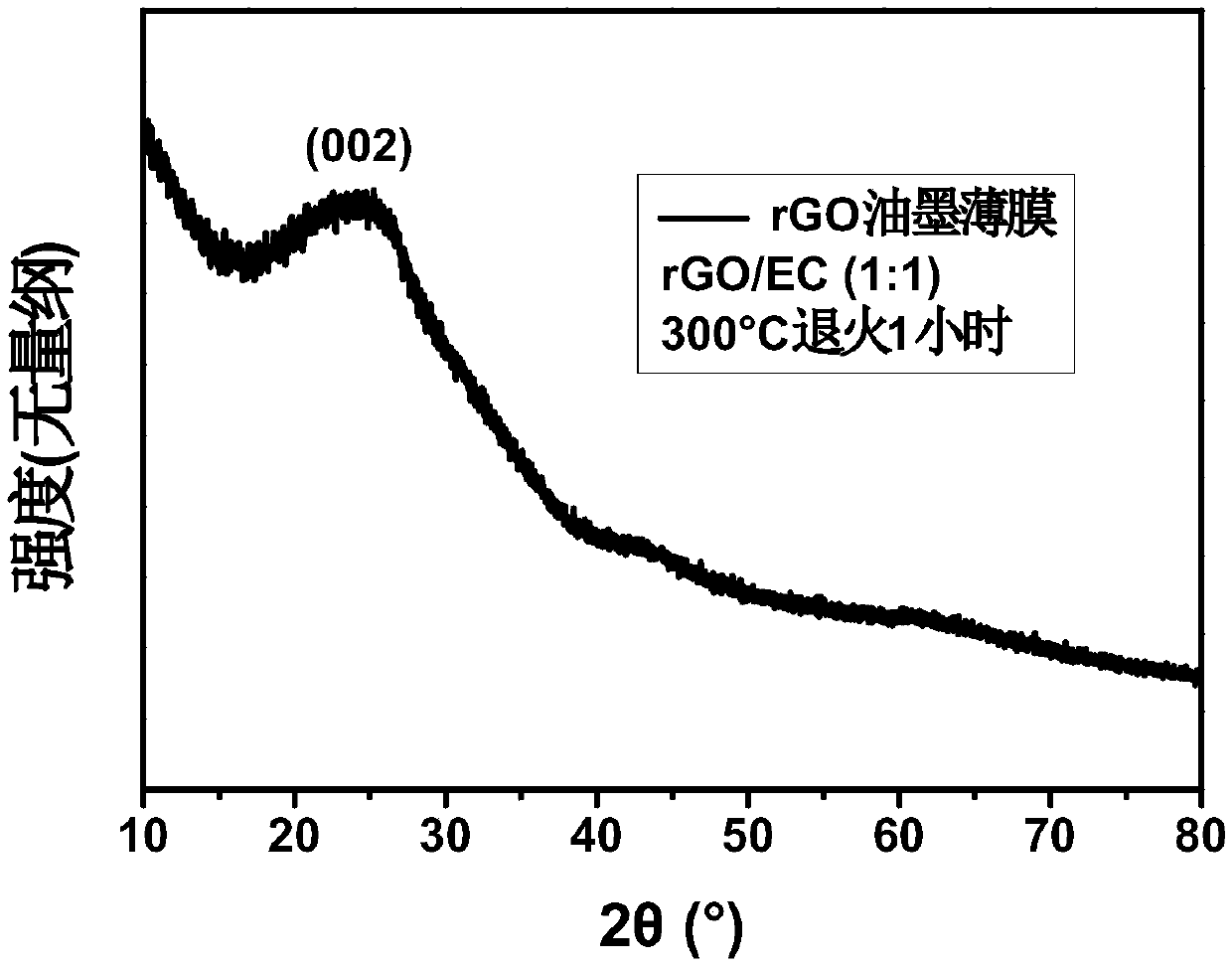

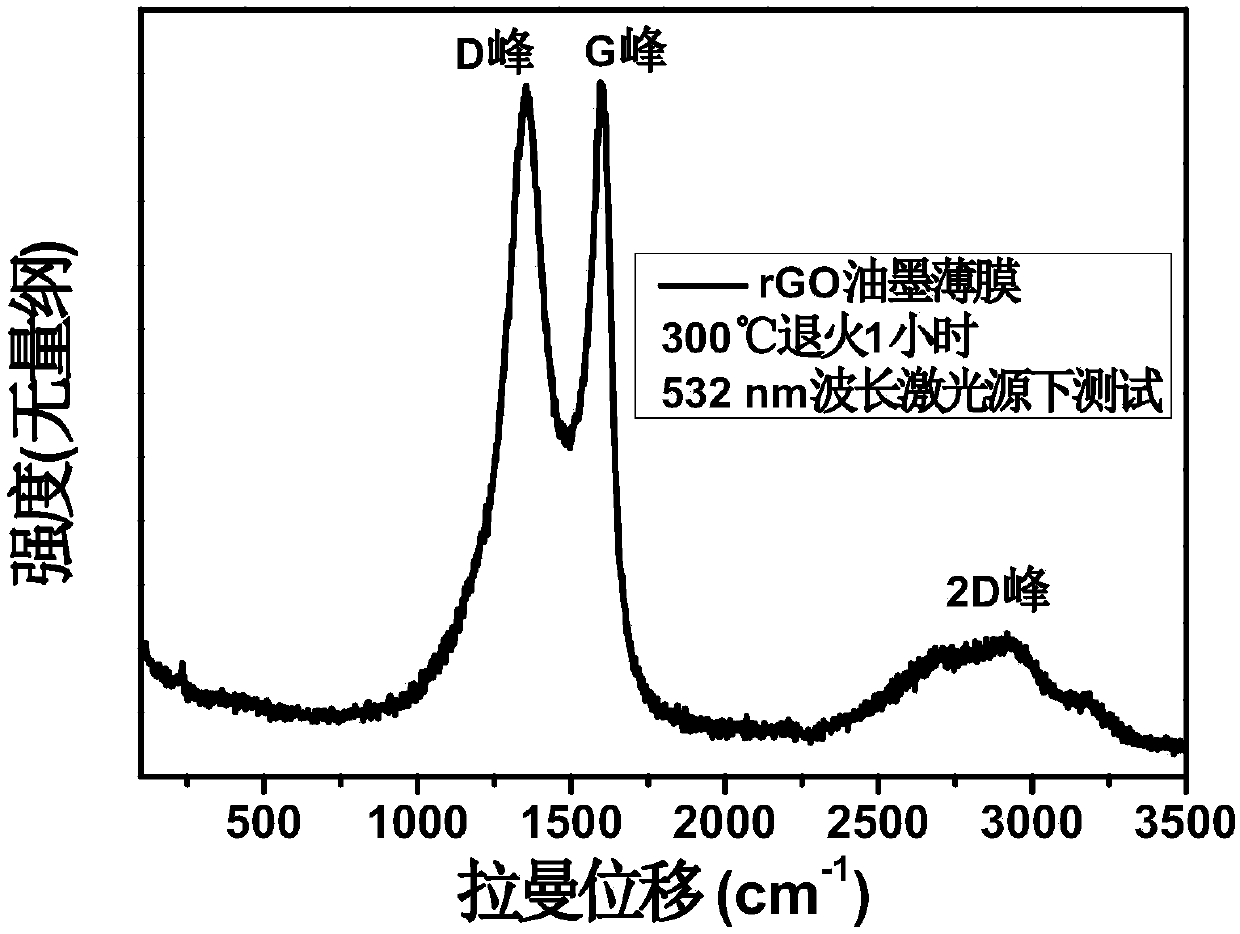

[0037] Weigh 0.25g of ethyl cellulose (viscosity specification: 50g / L 1:4 ethanol benzene solution, 40.0~100.0cP·s) into 30mL of absolute ethanol, stir at 500rpm for 1 hour at room temperature to obtain a uniform ethyl cellulose ethanol Solution; Weigh 0.25g redox graphene and add in ethyl cellulose ethanol solution, stir at room temperature with 500rpm for 0.5 hour to obtain graphene primary dispersion liquid, the microstructure of reduced graphene oxide is as follows figure 1 As shown, the reduced graphene oxide is sheet-like, with wrinkles and curls on the surface, indicating that the reduced graphene oxide is very thin and has fewer layers.

[0038] Place the graphene primary dispersion in an ice-water bath, and use an ultrasonic disperser to sonicate for 10 minutes under the ultrasonic mode of "running for 1 second and stopping for 2 seconds" with an ultrasonic disperser, then add 5 mL of terpineol, and continue to ultrasonicate in the same mode for 20 minutes. minutes to...

Embodiment 2

[0041] Weigh 0.03g of nitrocellulose (viscosity specification: 50g / L 1:4 ethanol benzene solution, 4-10cP·s) into 25mL of absolute ethanol, stir at 500rpm at room temperature for 0.5 hours to obtain a uniform nitrocellulose ethanol solution; Take 0.03 g of reduced graphene oxide and add it to the nitrocellulose ethanol solution, and stir at 500 rpm for 15 minutes at room temperature to obtain a primary dispersion of redox graphene.

[0042] Put the primary dispersion of graphene in an ice-water bath, use an ultrasonic disperser at 150W power, ultrasonic mode of "running for 1 second, stopping for 2 seconds" for 10 minutes, then add 2mL of the target solution, the components of the target solution and their The volume ratio is: cyclohexanone: terpineol: diethylene glycol dimethyl ether ether is 80:15:5, continue to sonicate in the same mode for 20 minutes to obtain a secondary dispersion.

[0043] Transfer the secondary dispersion to an oil bath, heat and stir at 100° C. for 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com