Preparation method of organic modified graphene

A graphene and modification technology, applied in the field of two-dimensional nanomaterial graphene preparation, can solve the problems of difficult to separate morphology, long preparation period, low degree of graphene exfoliation, etc., to achieve efficient exfoliation, controllability and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

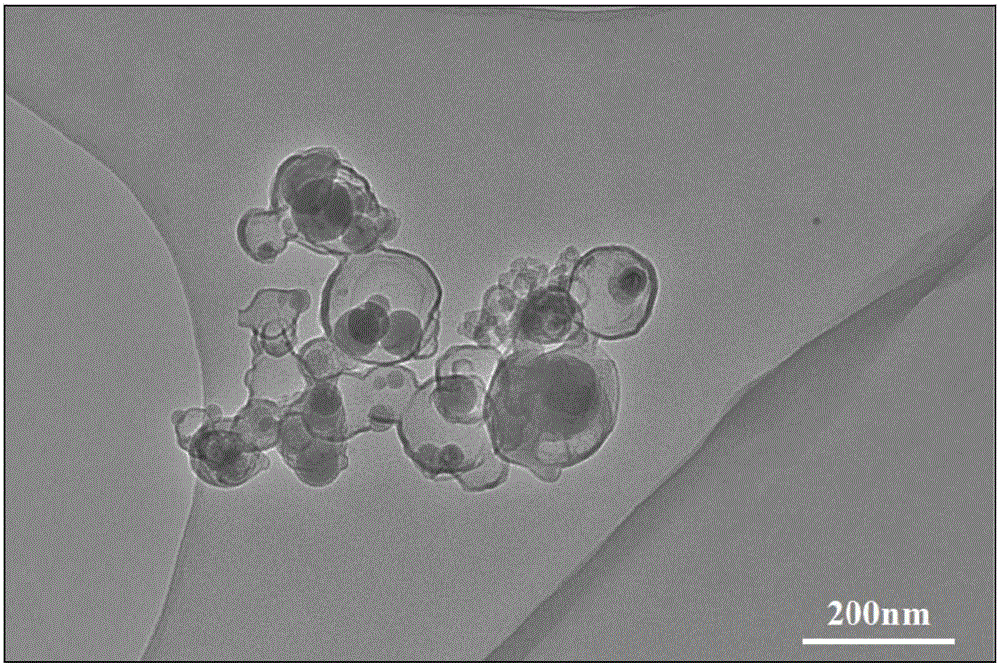

Image

Examples

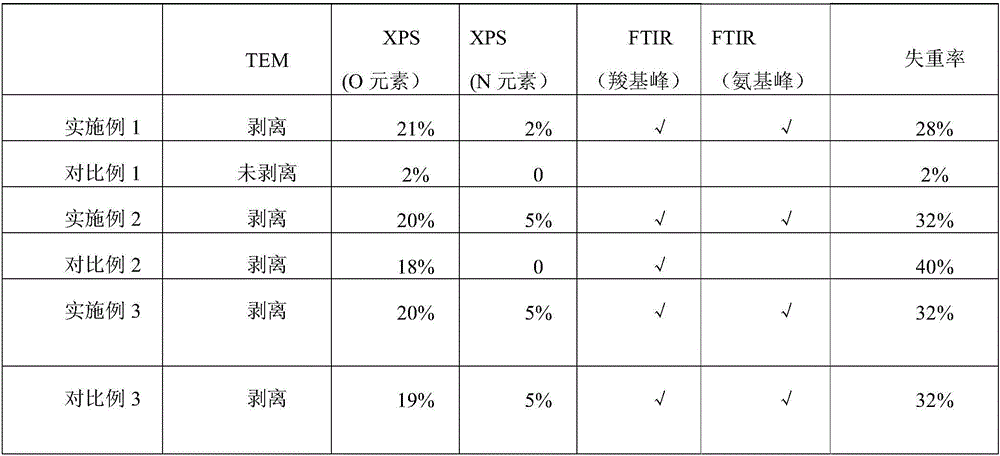

Embodiment 1

[0020] Original graphite, nitrogen-containing organic matter are as 10:1 as in ball mill jar with mass fraction, and selected original graphite is the graphite powder of common graphite ore processing; Nitrogen-containing organic matter monomer is aromatic amine solidifying agent diaminodiphenylmethane ( DDM) and aliphatic amine curing agent ethylenediamine in a mass ratio of 1:1; the buffer solution is a Tris (HCl) solution with pH=8. Fill in carbon dioxide gas to make the pressure 15MPa, then close the air valve to seal the ball mill tank, set the ball mill speed to 600rpm for continuous ball milling for 48h, then add 5 parts by mass of buffer solution (calculated as 1 part by mass of nitrogen-containing organic matter, the following examples Same) and continue ball milling for 24 hours. After degassing, the resulting product was diluted with acetone and then ultrasonically treated for 60 minutes. After being centrifuged at 8000 rpm for 20 minutes, it was dialyzed for one day...

Embodiment 2

[0025]Original graphite, nitrogen-containing organic matter are as 10:5 as in the ball mill jar with mass fraction, and selected original graphite is the graphite powder of common graphite ore processing; Nitrogen-containing organic matter monomer is aromatic amine solidifying agent diaminodiphenylmethane ( DDM) and aliphatic amine curing agent ethylenediamine in a mass ratio of 1:1. ; The buffer solution is a Tris (HCl) solution with pH=8. Fill the carbon dioxide gas to make the pressure 10MPa, then close the air valve to seal the ball mill tank, set the speed of the ball mill to 600rpm and continue ball milling for 48 hours, then add 5 parts by mass of buffer solution and continue ball milling for 24 hours, after deflation, dilute the obtained product with acetone Sonicate for 60 minutes, centrifuge at 8000rpm for 20 minutes and then dialyze for one day using a dialysis bag with a molecular weight cut-off of 6000-10000, and freeze-dry the solution to obtain a black powder. ...

Embodiment 3

[0030] Original graphite, nitrogen-containing organic matter are as 10:5 as in the ball mill jar with mass fraction, and selected original graphite is the graphite powder of common graphite ore processing; Nitrogen-containing organic matter monomer is aromatic amine solidifying agent diaminodiphenylmethane ( DDM) and aliphatic amine curing agent ethylenediamine in a mass ratio of 1:1; the buffer solution is the polar solvent acetone. Fill the carbon dioxide gas to make the pressure 10MPa, then close the air valve to seal the ball mill tank, set the speed of the ball mill to 600rpm and continue ball milling for 48 hours, then add 5 parts by mass of buffer solution and continue ball milling for 24 hours, after deflation, dilute the obtained product with acetone Sonicate for 60 minutes, centrifuge at 8000rpm for 20 minutes and then dialyze for one day using a dialysis bag with a molecular weight cut-off of 6000-10000, and freeze-dry the solution to obtain a black powder. The obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com