Wet-process method of preparing modified micron/nano-magnesium hydroxide flame retardant

A technology of magnesium hydroxide and ultra-fine magnesium hydroxide, which is applied in chemical instruments and methods, dyeing organosilicon compound treatment, dyeing low molecular organic compound treatment, etc. problems such as rise, to achieve good coating modification effect, reduce viscosity, and promote the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

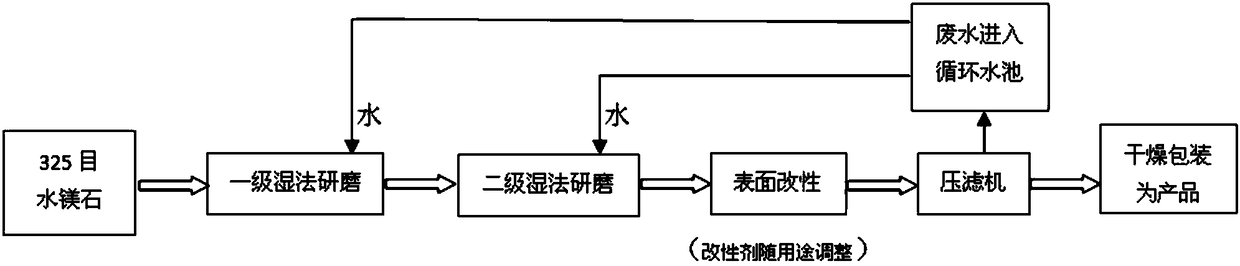

Method used

Image

Examples

Embodiment 1

[0022] (1) First, 1 part of monoethanolamine solution, 70 parts of water, and 15 parts of 325-mesh brucite powder raw materials are added to a primary wet grinder, and grinding balls are added to grind until the particle size is 2μm ultrafine magnesium hydroxide, the temperature is controlled at 100°C, the time of this stage is 60min, and the speed of the stirring mill is controlled at 60 rpm;

[0023] (2) Add the above-prepared ultrafine magnesium hydroxide suspension and 0.1 part of hyperdispersant to a secondary wet grinder, and add grinding beads for grinding, and grind to the target particle size of micronano hydroxide Magnesium slurry, the temperature is controlled at 100°C, the time at this stage is 100min, and the speed of the stirring mill is controlled at 60 rpm;

[0024] (3) adding the above-mentioned micro-nano magnesium hydroxide slurry and 0.2 part of composite modifier into the modification machine for modification to obtain the modified micro-nano magnesium hyd...

Embodiment 2

[0027] (1) First add 1.5 parts of diethanolamine solution, 80 parts of water, and 16 parts of 325-mesh brucite powder raw materials into a primary wet grinder, and add grinding media balls for grinding until the particle size It is 2 μm ultrafine magnesium hydroxide, the temperature is controlled at 90°C, the time of this stage is 100min, and the speed of the stirring mill is controlled at 100 rpm;

[0028] (2) Add the above-prepared ultrafine magnesium hydroxide suspension and 0.1 part of hyperdispersant to a secondary wet grinder, and add grinding beads for grinding, and grind to the target particle size of micronano hydroxide Magnesium slurry, the temperature is controlled at 100°C, the time of this stage is 60min, and the speed of the stirring mill is controlled at 60 rpm;

[0029] (3) adding the composite modifying agent in the above-mentioned micronano magnesium hydroxide slurry and 0.5 part to modify in the modifying machine, obtain the modified micronano magnesium hydr...

Embodiment 3

[0032] (1) First add 2 parts of diethanolamine solution, 100 parts of water, and 20 parts of 325-mesh brucite powder raw materials into a primary wet grinder, and add grinding media balls for grinding until the particle size It is 2 μm ultrafine magnesium hydroxide, the temperature is controlled at 120°C, the time of this stage is 75min, and the speed of the stirring mill is controlled at 100 rpm;

[0033] (2) Add the above-prepared ultrafine magnesium hydroxide suspension and 0.1 part of hyperdispersant to a secondary wet grinder, and add grinding beads for grinding, and grind to the target particle size of micronano hydroxide Magnesium slurry, the temperature is controlled at 100°C, the time of this stage is 60min, and the speed of the stirring mill is controlled at 60 rpm;

[0034] (3) adding the composite modifying agent in the above-mentioned micronano magnesium hydroxide slurry and 0.5 part to modify in the modifying machine, obtain the modified micronano magnesium hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com