A kind of preparation method of conductive polyurethane prepolymer and its conductive adhesive

A polyurethane prepolymer and conductive adhesive technology, applied in the field of conductive adhesive, can solve problems such as inability to improve electrical conductivity, uneven dispersion of the conductive adhesive system, and unusable products, so as to improve production efficiency, eliminate grain boundaries, and solve The effect of spreading the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of conductive polyurethane prepolymer, comprising the following steps:

[0034] (1) Prepare an aqueous solution of polyhydric alcohol with a concentration of 30-100wt%, and preheat to 40-60°C;

[0035] (2) dissolving silver nitrate accounting for 1-30wt% of the current content in the above-mentioned aqueous solution;

[0036] (3) adding nano-silver surface protection agent, its consumption is controlled within the 1wt% that accounts for current silver ion content; Nano-silver surface protection agent is organic carboxylic acid or organic amine, obtains silver ion solution;

[0037] Organic carboxylic acids contain 2 or more carbon atoms, and organic amines contain 2 or more carbon atoms;

[0038] (4) preparation of reducing agent aqueous solution; then drop reducing agent aqueous solution to the silver ion solution obtained in step (3), the reducing agent aqueous solution and silver ion solution proportioning 1: [0.1-1);

[0039] (5) Heating to 10...

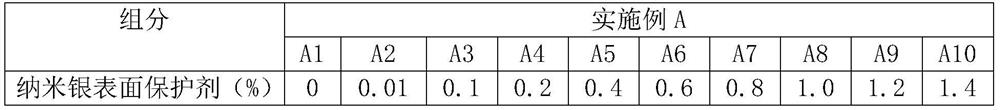

Embodiment A

[0073] A preparation method of conductive polyurethane prepolymer, comprising the following steps:

[0074] (1) Prepare an aqueous solution of polyhydric alcohol with a concentration of 50 wt%, and preheat it to 50°C; the polyhydric alcohol is polyethylene glycol and polypropylene glycol, and the molecular weight is controlled at 1000-2000g / mol;

[0075] (2) dissolving silver nitrate accounting for 5wt% of the current content in the above-mentioned aqueous solution;

[0076] (3) add nano-silver surface protection agent, its concentration is controlled in the scope as shown in table 1; Surface protection agent is caprylic acid;

[0077] (4) Prepare an aqueous solution of hydrazine hydrate and sodium borohydride water combination, the concentration is 20g / L; then drop the reducing agent aqueous solution to the silver ion solution obtained in step (3), the reducing agent aqueous solution and silver ion solution ratio 1:0.9 ;

[0078] (5) Heat to 100°C, and after 40 minutes of r...

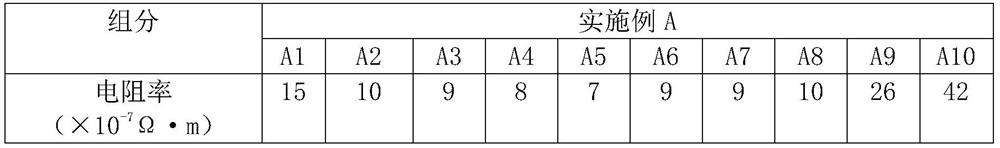

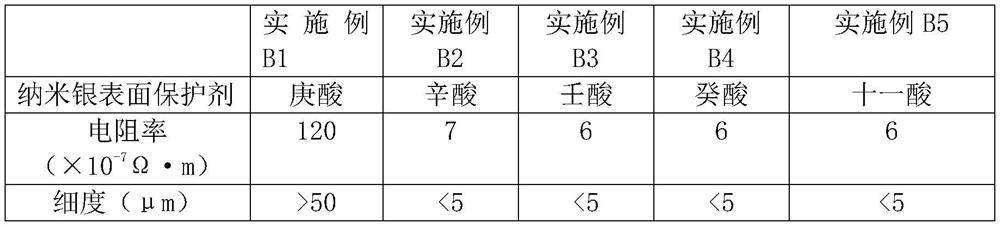

Embodiment B

[0090] A preparation method of conductive polyurethane prepolymer, comprising the following steps:

[0091] (1) Prepare an aqueous solution of polyhydric alcohol with a concentration of 50 wt%, and preheat it to 50°C; the polyhydric alcohol is polyethylene glycol and polypropylene glycol, and the molecular weight is controlled at 1000-2000g / mol;

[0092] (2) dissolving silver nitrate accounting for 5wt% of the current content in the above-mentioned aqueous solution;

[0093] (3) add nano-silver surface protection agent, its concentration is controlled at 0.4%; Surface protection agent is as shown in table 3;

[0094] (4) Prepare an aqueous solution of hydrazine hydrate and sodium borohydride water combination, the concentration is 20g / L; then drop the reducing agent aqueous solution to the silver ion solution obtained in step (3), the reducing agent aqueous solution and silver ion solution ratio 1:0.9 ;

[0095] (5) Heat to 100°C, and after 40 minutes of reaction, vacuumize ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com