Multilayer combined type vacuum stone molding device

A molding device and combined technology, applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., to achieve the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

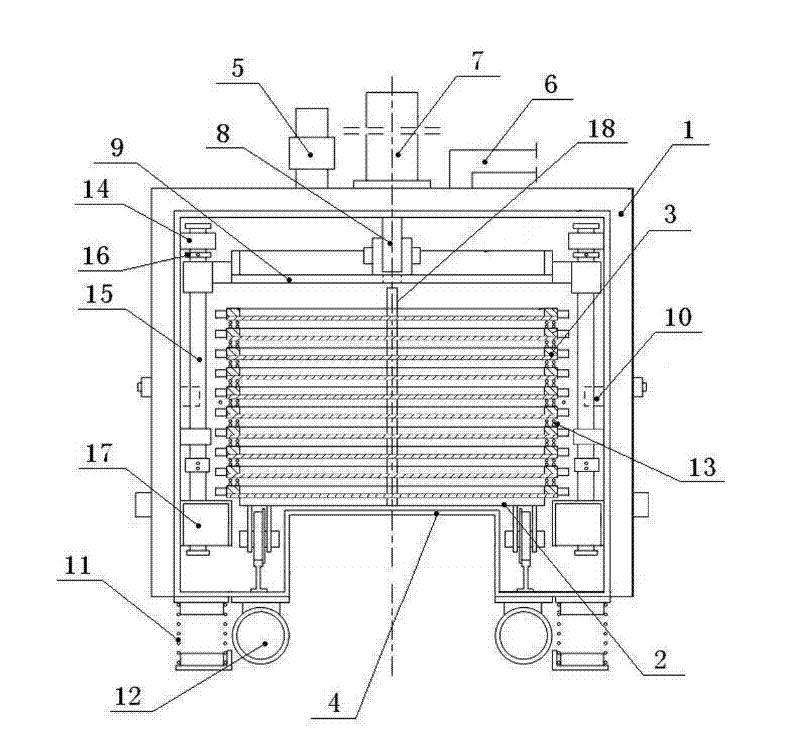

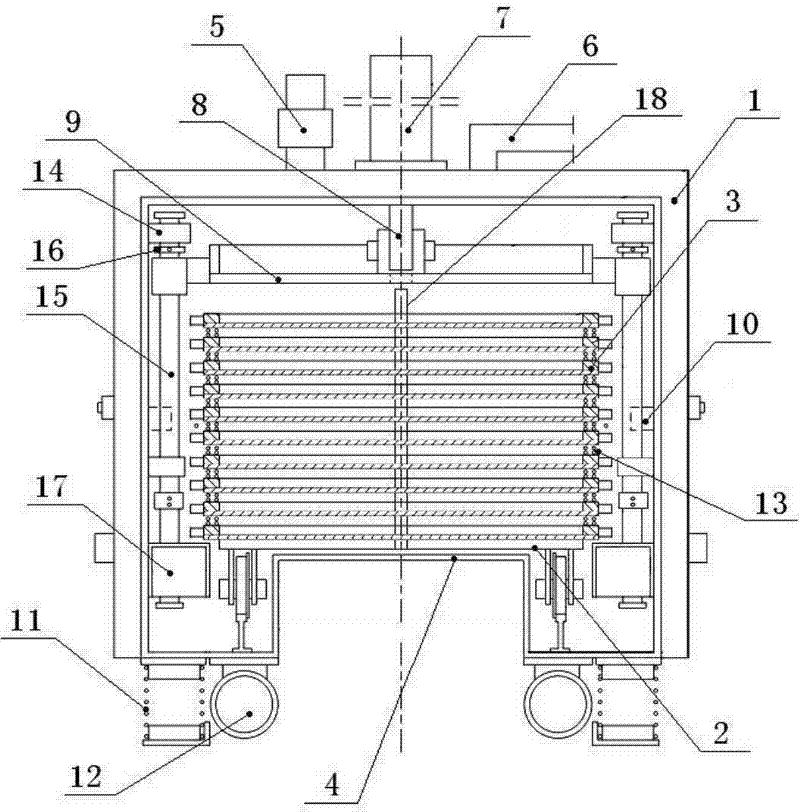

[0020]Carbon steel plates with a thickness of 10mm are used to make 8 templates 3 with a frame. The thickness of the frame is 24mm. The edges of the two are aligned and spot welded into a whole. A number of circular holes with a diameter of 38 mm and a depth of 30 mm are drilled on the center line in the length direction, and a cylinder with a diameter of 16 mm is welded on the lower surface of the template corresponding to the circular hole position, forming the upper and lower templates 3. The cylinder and the circular hole can be inserted fit the structure, then the length H o The compression spring 13 with a stiffness K of 80mm and a stiffness K of 130N / mm is assembled in the cylinders and round holes corresponding to the adjacent upper and lower templates 3, starting from the gap between the first template 3 and the second template 3 on the uppermost layer , select the number of compression springs 13 in turn: 4, 8, 16, 32, 64, 128, 256, so that the gap distance between t...

Embodiment 2

[0023] The template 3 of this example shares 3 pieces, and the height of the mold frame is 35cm, and the width is 3cm, and the bottom of the mold frame is a bolt fastening structure with the template 3; The number of compression springs between them is 12 and 18 respectively from top to bottom, so that the gap distance between the three-layer formwork is kept at about 100mm; two vibrators 12 are installed at the bottom of the vacuum box 1, and the distance between them is 60mm. ° electrical angle for flow control to generate a frequency of 50Hz.

[0024] In this example, Dunhuang jade from Guazhou, Gansu and hibiscus stone from Inner Mongolia are used to form a closely stacked block body. The particle size of the stone is 2-15cm; the mixture used to fill the gap is resin with a mass ratio of 10%. , 22% aluminum hydroxide powder and transparent stone particles with a particle size of 1-10mm are mixed together to form a viscous material body; the stones are arranged in two layer...

Embodiment 3

[0026] Basically the same as embodiment 1, the difference is: template 3 shares 6 pieces, and the number of compression springs between each template is 8, and the installation method of compression spring 13 is the same as embodiment 1; The template 3 on the upper layer is lifted and compressed at a lower frequency of 0.02 Hz; the vibrator 12 installed at the bottom of the vacuum box is 4 hydraulic exciters, and the plug rod of the exciter passes through the bottom plate of the vacuum box 1 and pushes to On both sides of the lowermost template 3, the template 3 is vibrated at a vibration frequency of 150 Hz. In this example, agate and crystal saws are used to closely splice the cracked broken boards with a gap width of 1-3mm. The matrix is made of 20% by mass polyester resin liquid, aluminum hydroxide powder and crystal sand. Sticky material, made of siliceous jade thin plate whose surface layer is artistically spliced, and the substrate and siliceous jade gap are light-tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com