High-beta-phase compact silicon nitride ceramic and low-temperature preparation method

A silicon nitride ceramic and dense technology, which is applied in the field of silicon nitride ceramics, can solve the problems of difficult solid-phase sintering, high sintering temperature, and reduced industrial production efficiency, so as to increase the content of β-silicon nitride phase and promote nitridation. Silicon phase transition, the effect of maintaining excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

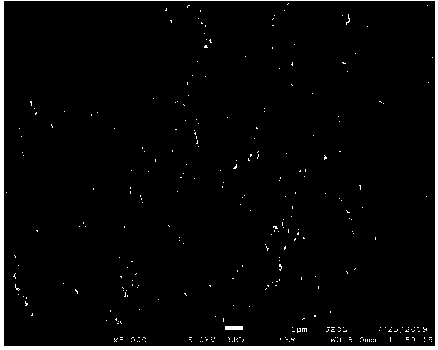

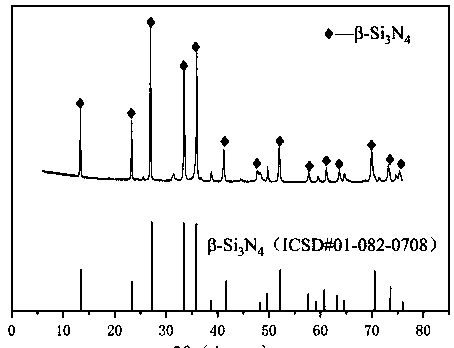

Image

Examples

Embodiment 1

[0033] According to Li 2 O (raw material is Li 2 CO 3 ) and Al 2 o 3 The molar ratio is 1.02:1, and then ball milling is carried out on a planetary ball mill for 6 hours. The ball milling medium is silicon nitride balls, and the ball-to-material ratio is 5:1.

[0034] The mixed powder after ball milling was dried and put into an alumina crucible for calcination at 1000°C for 2h.

[0035] The single-phase LiAlO obtained after calcination 2 Grind through 40 mesh sieve with Y 2 o 3 and Si 3 N 4 The powder is mixed according to the mass ratio of 10:2:88, and ball milled on a planetary ball mill for 24 hours. The ball milling medium is silicon nitride balls, and the ball-to-material ratio is 5:1.

[0036] Then spray granulate the uniformly mixed powder, the process is N 2 Atmosphere, set the inlet temperature at 160°C and the outlet temperature at 80°C to obtain Si 3 N 4 Granulated powder.

[0037] The granulated Si 3 N 4 The powder is put into an isostatic pressing ...

Embodiment 2

[0041] According to Li 2 O (raw material is Li 2 CO 3 ) and Al 2 o 3 The molar ratio is 1.02:1, and then ball milling is carried out on a planetary ball mill for 6 hours. The ball milling medium is silicon nitride balls, and the ball-to-material ratio is 7:1.

[0042] After ball milling, the mixed powder was dried and put into an alumina crucible for calcination at 900°C for 3h.

[0043] The single-phase LiAlO obtained after calcination 2 Crushed through 40 mesh sieve and Y 2 o 3 and Si 3 N 4 The powder is mixed according to the mass ratio of 8:4:88, and ball milled on a planetary ball mill for 24 hours. The ball milling medium is silicon nitride balls, and the ball-to-material ratio is 7:1.

[0044] Then spray granulate the uniformly mixed powder, the process is N 2 Atmosphere, set the inlet temperature at 180°C and the outlet temperature at 90°C to obtain Si 3 N 4 Granulated powder.

[0045] The granulated Si 3 N 4 The powder is put into an isostatic pressing ...

Embodiment 3

[0049] According to Li 2 O (raw material is Li 2 CO 3 ) and Y 2 o 3 The molar ratio is 1.5:1, and then ball milling is carried out on a planetary ball mill for 12 hours. The ball milling medium is silicon nitride balls, and the ball-to-material ratio is 10:1.

[0050] After the ball-milled sintering aid mixed powder is dried, it is put into an alumina crucible for calcination at 1300°C for 2 hours.

[0051] Calcined single-phase LiYO 2 Crushed through 40 mesh sieve with MgO and Si 3 N 4 The powder is mixed according to the mass ratio of 4:8:88, and ball milled on a planetary ball mill for 24 hours. The ball milling medium is silicon nitride balls, and the ball-to-material ratio is 10:1.

[0052] Then spray granulate the uniformly mixed powder, the process is N 2 Atmosphere, set the inlet temperature at 180°C and the outlet temperature at 90°C to obtain Si 3 N 4 Granulated powder.

[0053] The granulated Si 3 N 4 The powder is put into an isostatic pressing mold an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com