Pressure control adjustable strontium barium titanate-based composite ceramic materials and method for preparing same

A technology of composite ceramics and strontium barium titanate, which is applied in the field of voltage-controlled adjustable strontium barium titanate-based composite ceramic materials and its preparation, can solve the problem of high microwave dielectric loss and achieve the effect of improving sintering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

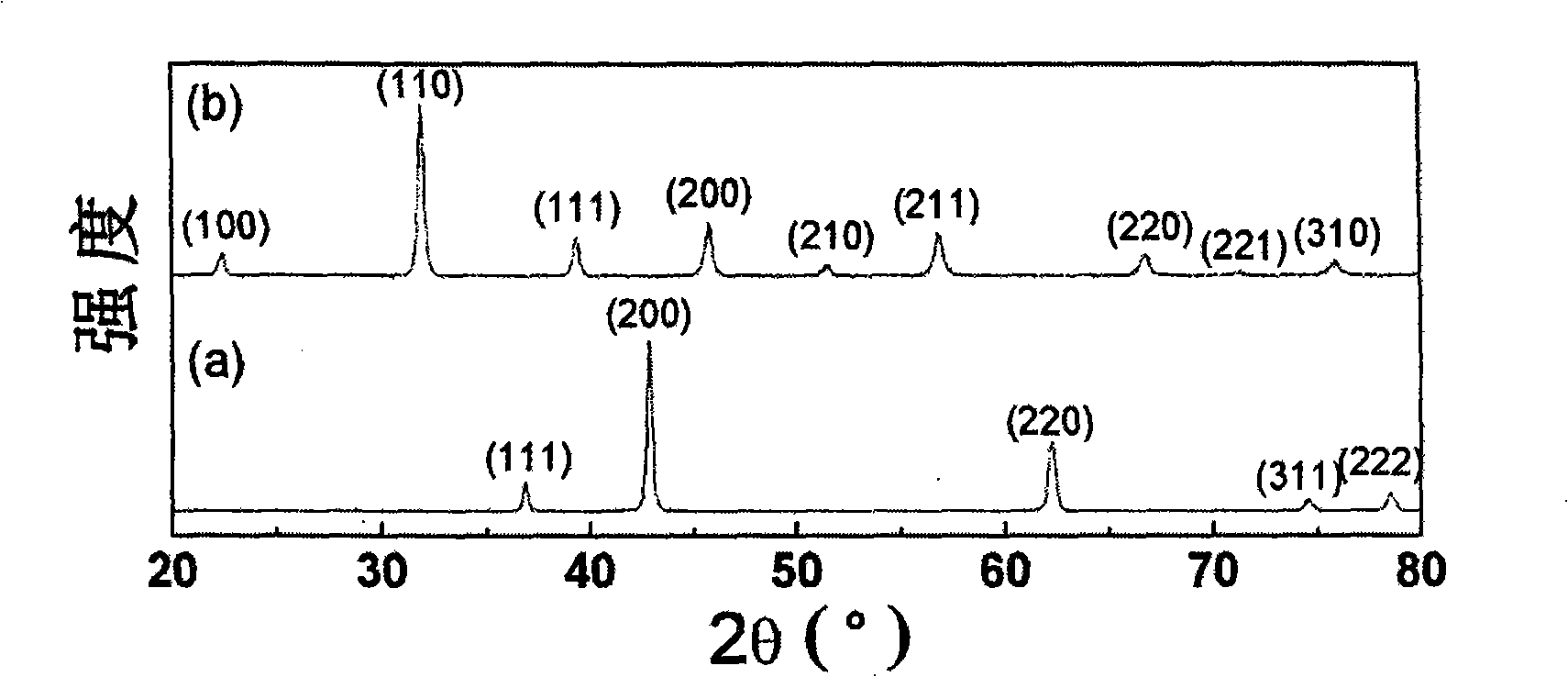

[0041] Press Ba 0.6 Sr 0.4 TiO 3 Stoichiometric Dosage Ratio Weighing BaCO 3 , SrCO 3 and TiO 2 , put into the agate mixing tank, add agate balls and alcohol, mix on the three-roller mixer for 24 hours, the volume ratio of agate balls, alcohol and powder is 6:2:1, and mix the above slurry at 100°C Dry in an oven, and then pre-burn in air at 1100 °C for 4 hours to obtain Ba 0.6 Sr 0.4 TiO 3 Powder. by Mg 0.9 Zn 0.1 O stoichiometric ratio Weigh MgO and ZnO, use the same method to prepare Mg 0.9 Zn 0.1 O powder. The X-ray analysis results of these two powders are as follows: figure 1 shown.

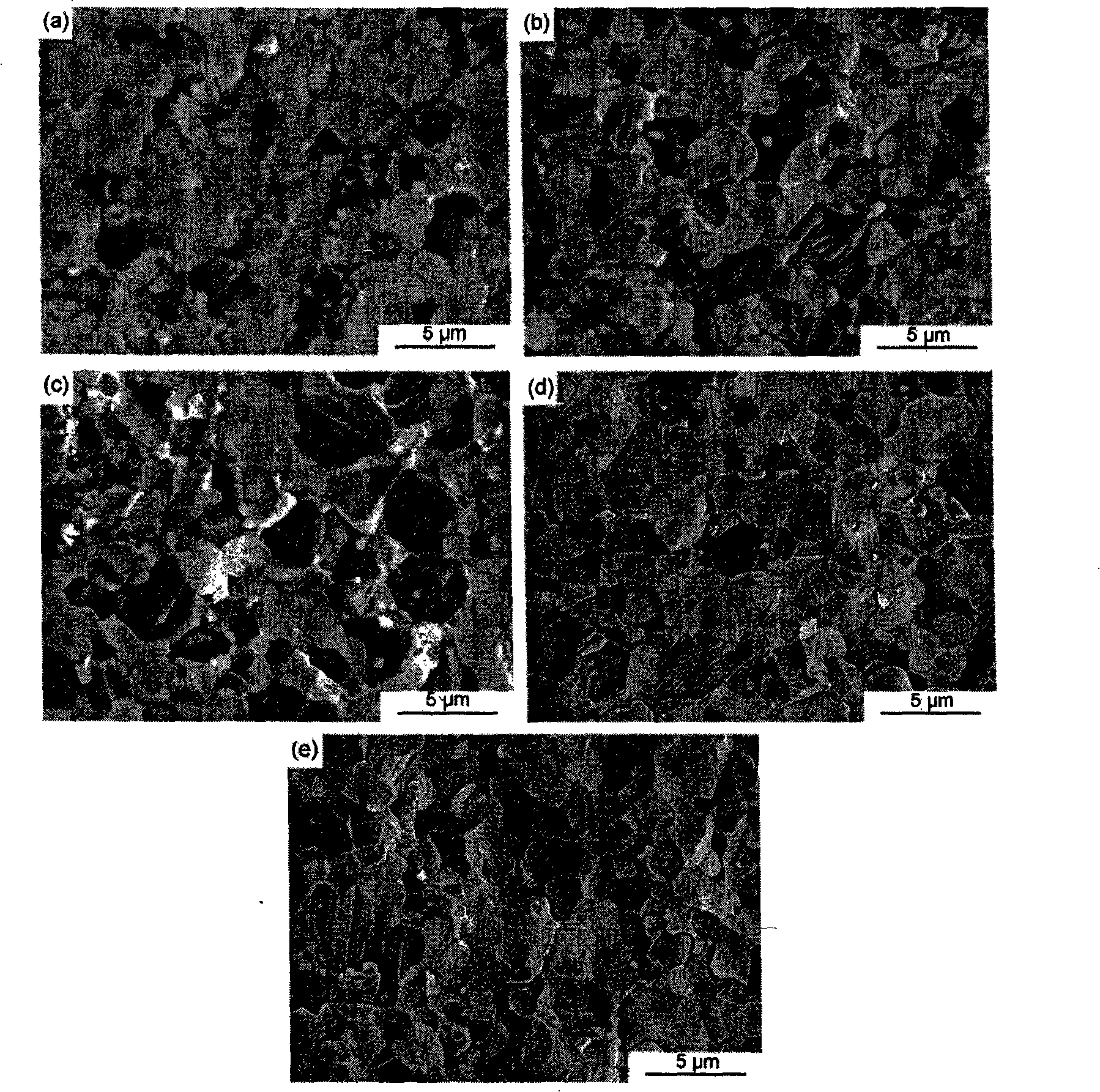

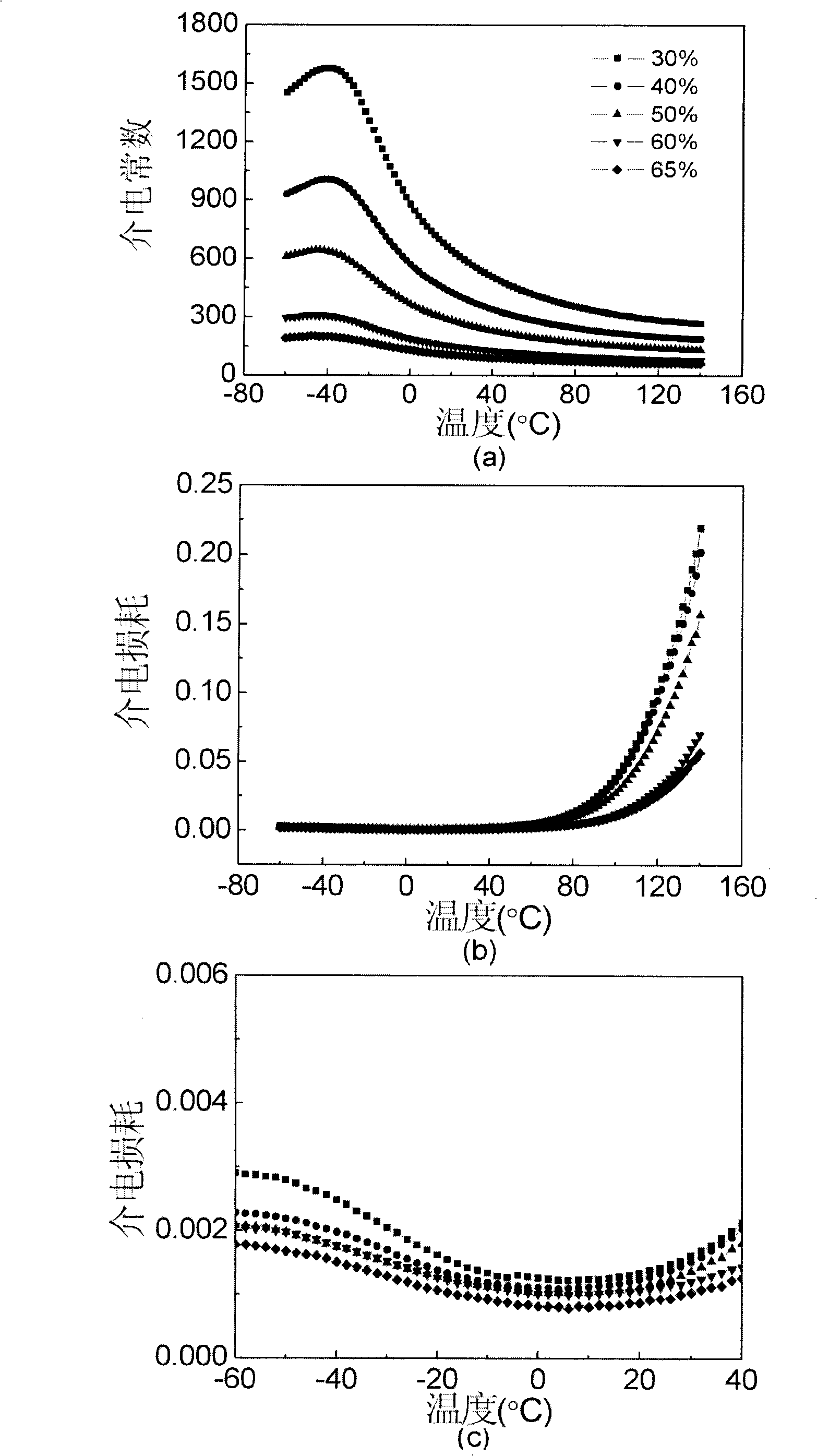

[0042] By (1-m) Ba 0.6 Sr 0.4 TiO 3 -mMg 0.9 Zn 0.1 The weight percent m in O is 30%, 40%, 50%, 60% and 65%, respectively, and Ba 0.6 Sr 0.4 TiO 3 and Mg 0.9 Zn 0.1 O, then the Ba of the above five m values 0.6 Sr 0.4 TiO 3 and Mg 0.9 Zn 0.1 O powders were respectively put into the agate mixing tank, added agate balls and alcohol and mixed on a three-roll mixer f...

Embodiment 2

[0048] Using the same process as in Example 1 to prepare Ba respectively 0.6 Sr 0.4 TiO 3 and Mg 1-y Zn y O ceramic powder, where y values are 0, 0.05, 0.1, 0.15 and 0.2 respectively, and Mg 1-y Zn y O at (1-m) Ba 0.6 Sr 0.4 TiO 3 -mMg 1-y Zn y The weight percentage m in O composite ceramics is 65%, that is, 35% Ba 0.6 Sr 0.4 TiO 3 -65% Mg 1-y Zn y O composite ceramics.

[0049] Figure 7 for Mg 1-y Zn y The XRD analysis result of O powder, it can be seen that, within the range of ZnO doping amount of the present invention, Mg 1-y Zn y O is a single solid solution, and the crystal structure type of the solid solution is consistent with MgO crystal, while MgO is a cubic crystal system, and ZnO is a hexagonal crystal system.

[0050] Figure 8 for Ba 0.6 Sr 0.4 TiO 3 -Mg 1-y The test curves of tuning rate, dielectric loss and FOM value of ZnyO composite ceramics with a test frequency of 500 Hz as a function of y value.

[0051] Table 2 lists the 35% B...

Embodiment 3

[0055] 36wt.% Ba was prepared by the same process as in Example 1 0.6 Sr 0.4 TiO 3 -64% Mg 0.9 Zn 0.1 O composite ceramic powder. Divide the composite ceramic powder into five parts and add Ta 2 o 5 Powder, Ta 2 o 5 The weight percent content is respectively 0.00wt, 0.10wt, 0.50wt, 1.00wt and 2.00wt, and then respectively put into agate jars, and then add agate balls and alcohol. Put it on a three-roller mixer and mix for 24 hours. The volume ratio of agate balls, alcohol and ceramic powder is 6:2:1. The slurry was dried in an oven at 100°C, and after uniaxial cold pressing and cold isostatic pressing, it was sintered at 1440°C under normal pressure for 5 hours, and then the five kinds of Ta 2 o 5 The dielectric properties of the composite ceramics with weight percent content were analyzed, and the analysis results are shown in Table 3.

[0056] Table 336wt.% Ba 0.6 Sr 0.4 TiO 3 -64% Mg 0.9 Zn0.1O-Ta 2 o 5 Dielectric Properties of Ceramics

[0057] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com