Embedded chip printed circuit board and method of manufacturing the same

a printed circuit board and embedded chip technology, applied in the association of printed circuit non-printed electric components, printed circuits, etc., can solve the problems of large circuit space, difficult to manufacture an embedded chip pcb which is light, slim, short and small, and suffers from the conventional method of manufacturing an embedded chip pcb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, a detailed description will be given of an embedded chip PCB and a method of manufacturing the same, according to the present invention, with reference to the appended drawings.

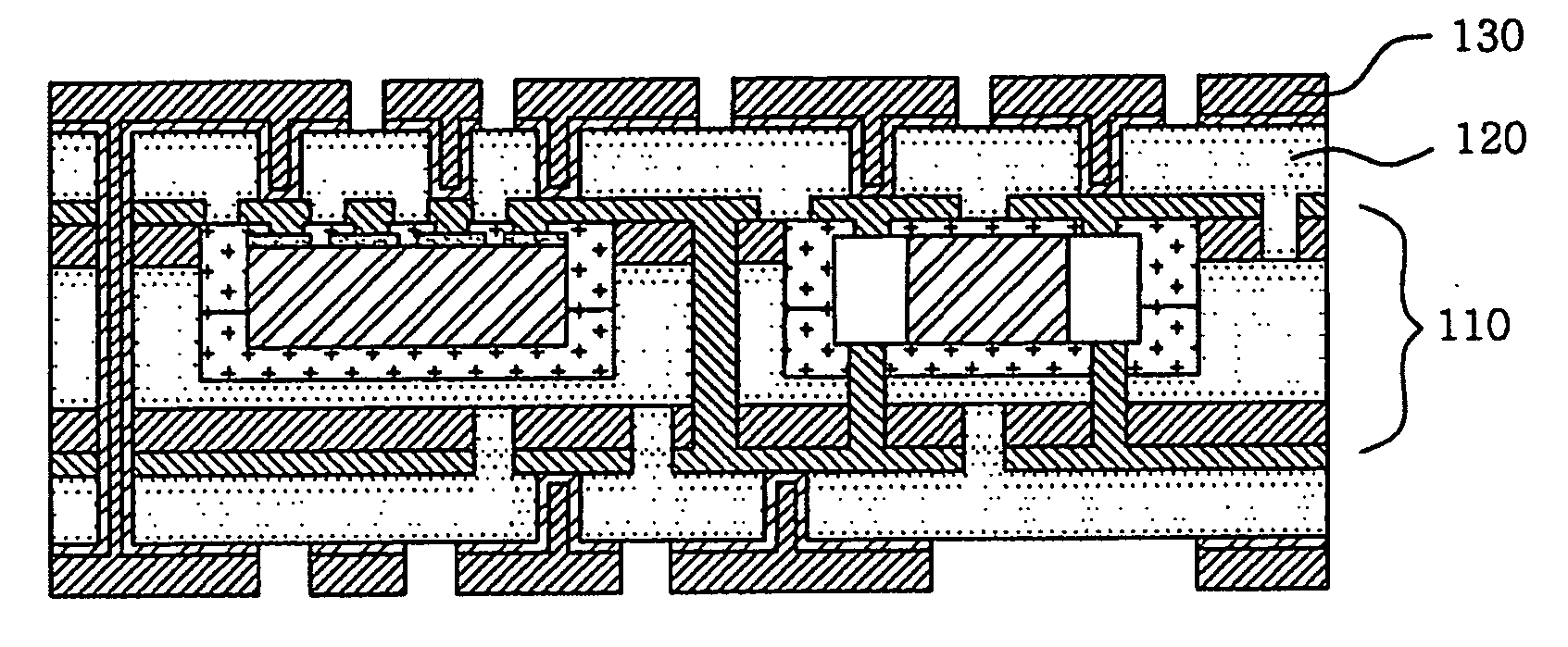

[0037]FIG. 2 is a cross-sectional view showing an embedded chip PCB, according to the present invention.

[0038] As shown in FIG. 2, the embedded chip PCB, according to the present invention, includes a core layer 110, which includes a CCL having an insulating layer and thin copper foils provided on both surfaces thereof, chips embedded in the CCL, inner circuit pattern layers formed on upper and lower surfaces of the CCL, and via holes for use in the electrical connection of the inner circuit pattern layers and the embedded chips. In addition, the embedded chip PCB includes an insulating layer 120 laminated on each of the upper and lower surfaces of the core layer 110 and having via holes formed therethrough, and an outer circuit pattern layer 130 laminated on the insulating layer 120 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com