Carbonate precursor and preparation method and application thereof

A precursor and carbonate technology, applied in chemical instruments and methods, inorganic chemistry, electrical components, etc., can solve the problems of affecting the electrochemical performance of materials, uneven lithiation of ternary precursors, and complicated operations, and achieve cost Low, smooth surface, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

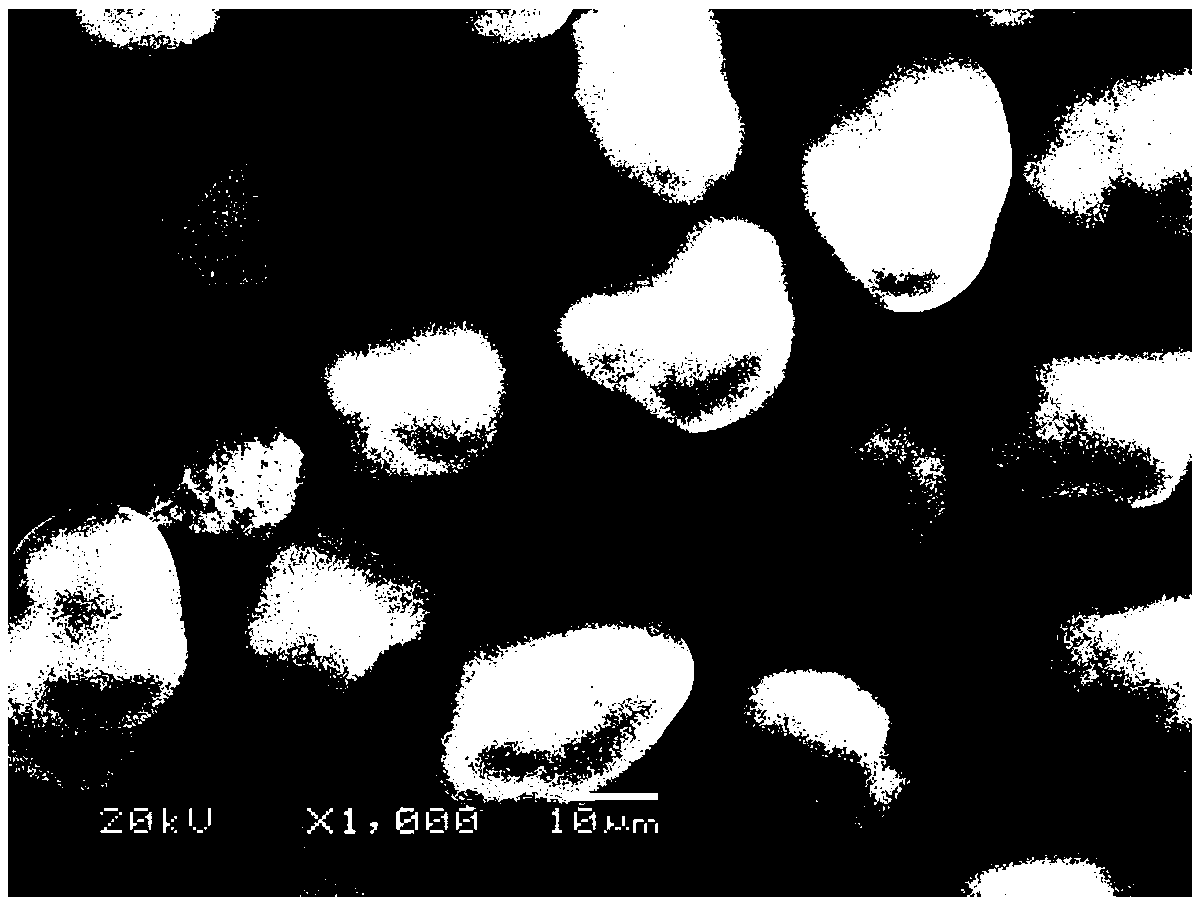

[0059] Nickel sulfate hexahydrate, cobalt sulfate heptahydrate, and manganese sulfate monohydrate are weighed in a 6:2:2 molar ratio, and are configured into solution a together with p-toluenesulfonamide, wherein the total concentration of metal ions is 1mol / L. The growth agent is 20g / L.

[0060] The mixture of sodium bicarbonate and ammonia water was selected as the precipitant, the molar ratio was 50:1, and the total concentration of the mixed precipitant was 4mol / L. Add the mixture of sodium bicarbonate and ammonia water into pure water as solution b, and the concentration sum of sodium bicarbonate and ammonia water in solution b is 0.5mol / L. Add solution a and solution b into the reaction kettle in parallel. This process is a batch reaction process. After the solid-liquid separation is completed by the solid-liquid separation device, the solid particles return to the kettle to continue the reaction until the reaction is completed. The technological conditions in the react...

Embodiment 2

[0062] Nickel chloride hexahydrate, cobalt chloride hexahydrate, and aluminum chloride hexahydrate are weighed in a molar ratio of 8.0:1.5:0.5, and they are configured together with sodium bisbenzenesulfonimide to form solution a, wherein the metal ion concentration is 1.5mol / L, the growth promoter is 15g / L. Ammonium bicarbonate was selected as the precipitating agent, and the concentration was 3mol / L ammonium bicarbonate solution. This ammonium bicarbonate solution was added to pure water to obtain solution b, and the concentration of solution b was 0.8 mol / L. Add solution a and precipitant solution b into the reaction kettle in parallel. This process is a batch reaction process. After the solid-liquid separation is completed by the solid-liquid separation device, the solid particles return to the kettle to continue the reaction until the reaction Finish. The technological conditions in the reaction process are: reaction temperature 45° C., pH 8.2, stirring speed 550 rpm. ...

Embodiment 3

[0064] The ternary precursor prepared in Example 2 was placed in a muffle furnace and calcined at 550° C. for 5 hours to fully decompose the carbonate and obtain spherical ternary oxide particles. The ternary oxide particles and lithium hydroxide were mixed at a ratio of 1:1.05, and sintered at a temperature of 800° C. for 12 hours in an oxygen atmosphere in a muffle furnace to obtain a ternary positive electrode material. The 1C cycle performance was tested in the voltage range of 2.8V-4.3V. The first charge and discharge efficiency was 85%, the first discharge capacity was 180.5mAh / g, and the capacity retention rate after 100 cycles was 95.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com