Gadolinium zirconate ceramic for curing TRPO simulated waste, and preparation method thereof

A technology of gadolinium zirconate and waste, applied in the field of nuclear energy, can solve the problems of inability to cure TRPO waste, the generation of impurity, and the influence of ceramic radiation resistance, so as to improve radiation resistance, inhibit the accumulation of point defects, The effect of improving the ability to resist radiation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] This embodiment is used to prepare gadolinium zirconate ceramics for solidifying 10wt% TRPO simulated waste, comprising the following steps:

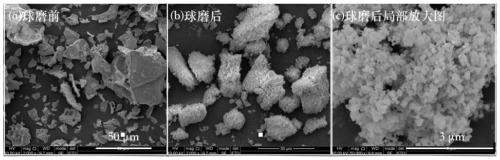

[0066] (1) Preparation of precursor powder

[0067] It is planned to prepare 25g of precursor powder, Gd in the precursor powder 2 Zr 2 o 7 Occupying the mass percent is 90wt%, and the mass percent accounting for TRPO simulated waste is 10wt%, then Gd 2 Zr 2 o 7 The mass of TRPO is 22.5g, and the mass of TRPO simulated waste is 2.5g. Gd can be calculated 2 Zr 2 o 7 Gd is 11.475g, Zr is 6.658g; TRPO simulated waste is calculated according to Table 2, Y is 0.095g, La is 0.248g, Ce is 0.477g, Pr is 0.2343g, Nd is 0.8123g, Eu is 0.03 g, Gd is 0.0373g, Sm is 0.1475g, Mo is 0.291g, Ru is 0.0567g, and Pd is 0.0743g. Among them, molybdenum, ruthenium and palladium use the corresponding oxides because there is no nitrate. According to the concentration of corresponding elements in the above-mentioned prepared nitrate solution a...

Embodiment 2

[0074] This embodiment is used to prepare gadolinium zirconate ceramics for solidifying 20wt% TRPO simulated waste, comprising the following steps:

[0075] (1) Preparation of precursor powder

[0076] It is planned to prepare 25g of precursor powder, Gd in the precursor powder 2 Zr 2 o 7 Occupying the mass percent is 80wt%, and the mass percent accounting for TRPO simulated waste is 20wt%, then Gd 2 Zr 2 o 7 The mass of TRPO is 20g, and the mass of TRPO simulated waste is 5g. Gd can be calculated 2 Zr 2 o 7 Gd is 10.328g, Zr is 5.992g; TRPO simulated waste is calculated according to Table 2, Y is 0.19g, La is 0.495g, Ce is 0.954g, Pr is 0.4685g, Nd is 1.6245g, Eu is 0.06 g, Gd is 0.0745g, Sm is 0.295g, Mo is 0.582g, Ru is 0.1135g, and Pd is 0.1485g. Among them, molybdenum, ruthenium and palladium use the corresponding oxides because there is no nitrate. According to the concentration of corresponding elements in the above-mentioned prepared nitrate solution and the...

Embodiment 3

[0083] This embodiment is used to prepare gadolinium zirconate ceramics for solidifying 30wt% TRPO simulated waste, comprising the following steps:

[0084] (1) Preparation of precursor powder

[0085] It is planned to prepare 25g of precursor powder, Gd in the precursor powder 2 Zr 2 o 7 Occupying the mass percent is 70wt%, and the mass percent accounting for TRPO simulated waste is 30wt%, then Gd 2 Zr 2 o 7 The mass of TRPO is 17.5g, and the mass of TRPO simulated waste is 7.5g. Gd can be calculated 2 Zr 2 o 7 Gd is 9.037g, Zr is 5.243g; TRPO simulated waste is calculated according to Table 2, Y is 0.285g, La is 0.745g, Ce is 1.431g, Pr is 0.7028g, Nd is 2.4368g, Eu is 0.09 g, Gd is 0.1118g, Sm is 0.4425g, Mo is 0.783g, Ru is 0.1703g, and Pd is 0.2228g. Among them, molybdenum, ruthenium and palladium use the corresponding oxides because there is no nitrate. According to the concentration of corresponding elements in the above-mentioned prepared nitrate solution an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com