Powder metallurgy method of Ti-6Al-4V alloy

A ti-6al-4v, powder metallurgy technology, applied in the field of powder metallurgy titanium, can solve the problems of restricting large-scale use, difficult processing, high cost of titanium alloys, etc., and achieve the effects of efficient and stable production, improved density, and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

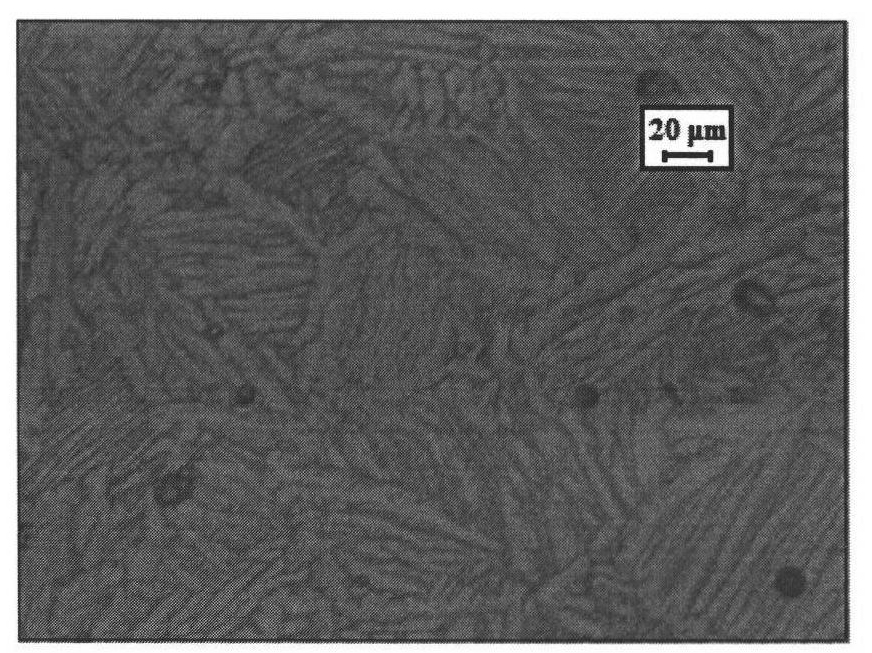

Embodiment 1

[0014] Lubricate the inner walls of the mold with an ethanol solution of zinc stearate. The -100 mesh Ti-6Al-4V alloy powder prepared by hydrogenation dehydrogenation method is used as raw material, and the ratio of impact energy to powder loading is 1065J: 9.65g. The powder is filled into the mold cavity, and after pre-pressing and exhausting, press green body. The green body was placed in a high vacuum sintering furnace, and sintered at 1250°C for 3 hours at a heating rate of 3°C / min, with a vacuum degree of 1×10 -3 ~1×10 -4 Pa. The powder metallurgy Ti-6Al-4V alloy was obtained with furnace cooling. The density measured by drainage method is 95.1%, the hardness HV is 261, and the compressive strength is 1600MPa.

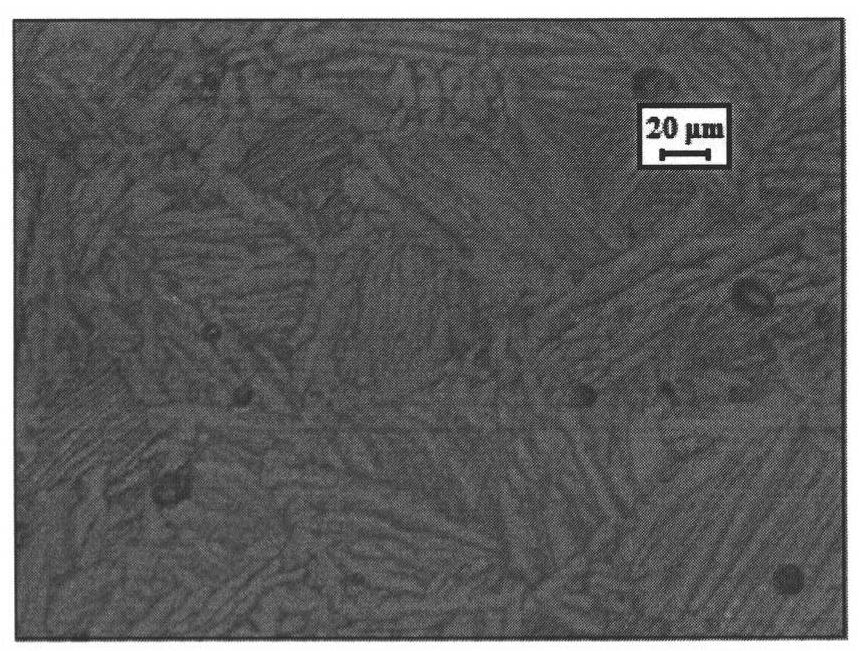

Embodiment 2

[0016] Lubricate the inner walls of the mold with an ethanol solution of zinc stearate. The -200 mesh Ti-6Al-4V alloy powder prepared by hydrogenation dehydrogenation method is used as the raw material, and the ratio of impact energy to powder loading is 913J: 8.43g. green body. The green body was placed in a high vacuum sintering furnace, and sintered at 1250°C for 3 hours at a heating rate of 3°C / min, with a vacuum degree of 1×10 -3 ~1×10 -4 Pa. After cooling with the furnace, the powder metallurgy Ti-6Al-4V alloy is obtained. The density measured by drainage method is 96.0%, the hardness HV is 302, and the compressive strength is 1890MPa.

Embodiment 3

[0018] Lubricate the inner walls of the mold with an ethanol solution of zinc stearate. The -300 mesh Ti-6Al-4V alloy powder prepared by hydrogenation dehydrogenation method is used as the raw material, and the ratio of impact energy to powder loading is 304J: 7.43g. green body. The green body was placed in a high vacuum sintering furnace, and sintered at 1250°C for 3 hours at a heating rate of 3°C / min, with a vacuum degree of 1×10 -3 ~1×10 -4 Pa. After cooling with the furnace, the powder metallurgy Ti-6Al-4V alloy is obtained. The density measured by drainage method is 95.8%, the hardness HV is 291, and the compressive strength is 1880MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com