Vacuum cleaner nozzle with rotatably limited base plate

A vacuum cleaner and rotation angle technology, applied in the direction of the suction nozzle, etc., can solve the problems of inability to distribute the flow, user effort, air leakage, etc., to achieve the best cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

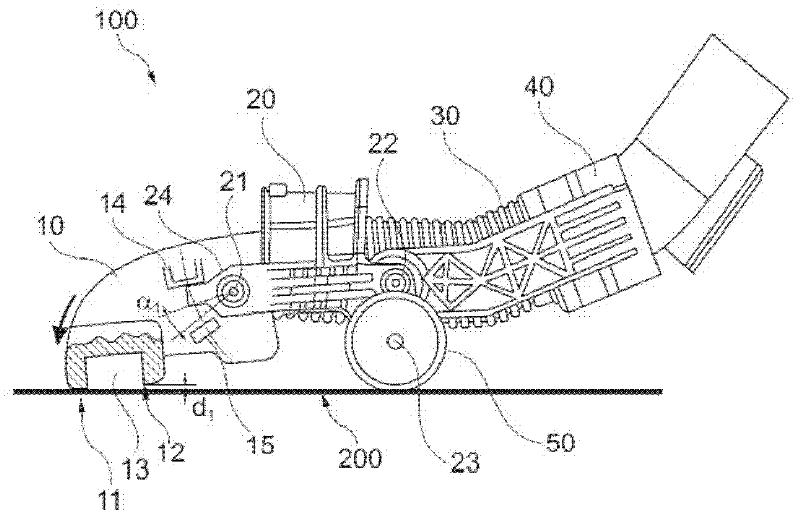

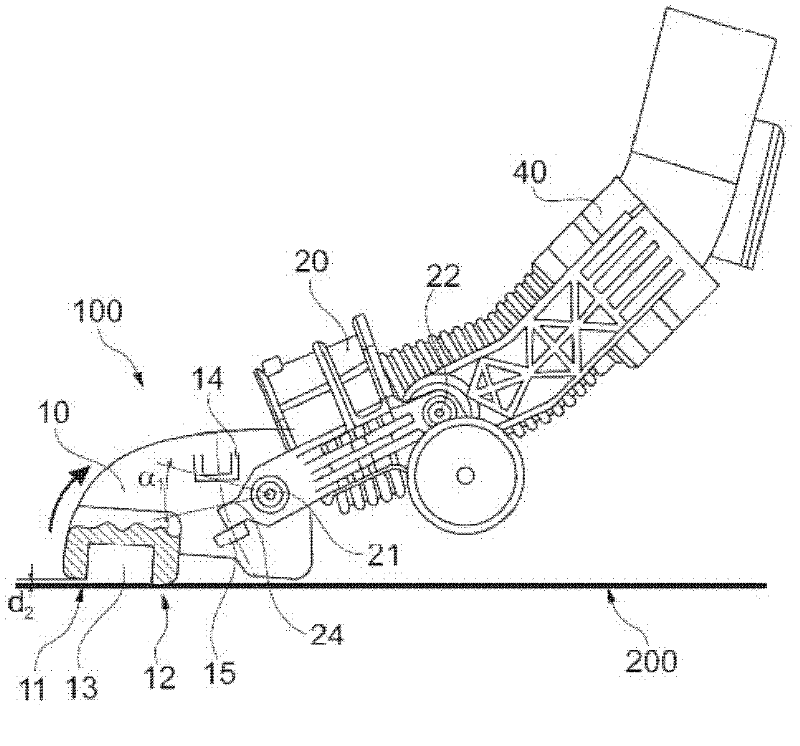

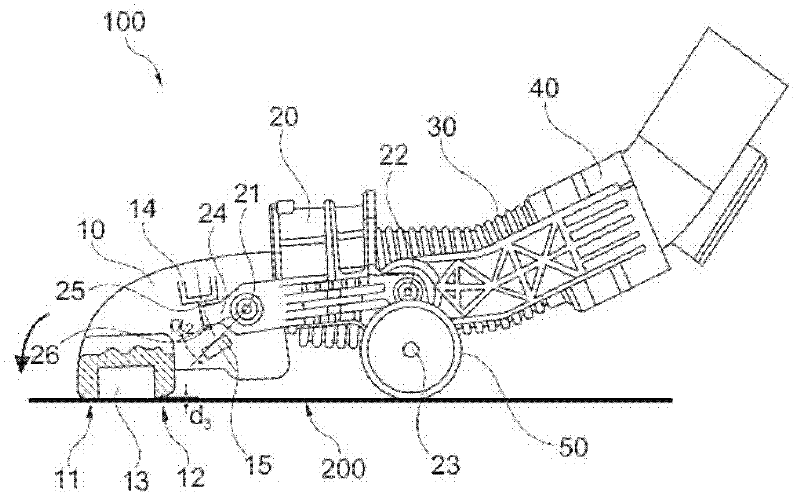

[0018] figure 1 A side view of a suction nozzle 100 of a vacuum cleaner is shown, wherein the suction nozzle 100 is pushed forward over a floor 200 to be cleaned. The suction nozzle 100 of the vacuum cleaner mainly includes a base 10 , the base 10 is connected with a transmission rod 20 , and the transmission rod 20 is connected with the rest of the vacuum cleaner through a connecting piece 40 and a rotating shaft 22 . In addition, the air drawn in flows through the flexible tube 30 which is arranged between the base and the connection piece 40 . The base 10 is rotatable about an axis 21 relative to a transmission rod 20 comprising at least one ground support roller 50 rotatable about an axis 23 to facilitate the use of the suction nozzle 100 . When the suction nozzle 100 moves forward, the user's pushing force is decomposed into a downward vertical component and a forward horizontal component. The roller 50 absorbs the vertical component on the ground, so it is easy for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com