Device for storing and mixing bone cement

A technology of bone cement and container, which is applied in mixers, distribution devices, shaking/oscillating/vibrating mixers, etc., can solve the problem of inability to use slurry polymethyl methacrylate bone cement and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

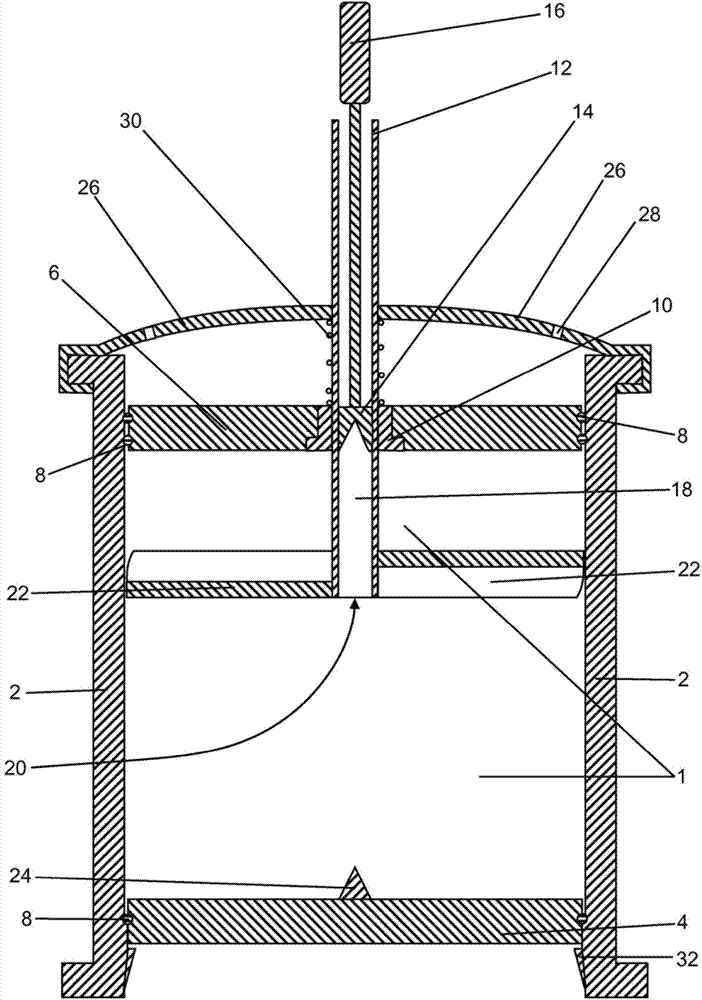

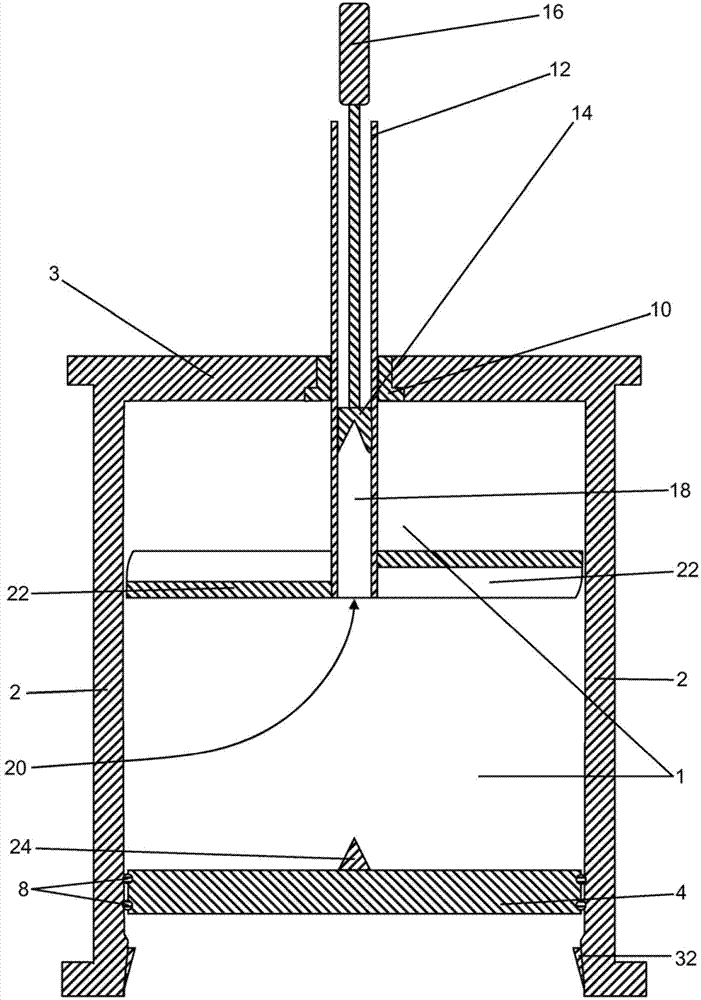

[0093] For simplicity, identical or similar components are identified with the same reference numerals in the figures. The cut surfaces are shown by hatching.

[0094] figure 1 A schematic cross-sectional view of a device according to the invention is shown. The device has a first container 1 with a cylindrical inner space which is filled or can be filled with a first component of PMMA bone cement. The first container 1 contained a slurry-like mass containing methyl methacrylate monomer as a first component. The first container 1 has on its side a wall 2 of a cylindrical plastic body for its boundary. The first container 1 is on its back (on figure 1 on the bottom in ) has a cylindrical dispensing plunger 4 for its border. The first container 1 is on its front side (in figure 1 on top of ) has a volume compensating element 6 in the form of a cylindrical plunger for its boundary. The dispensing plunger 4 as well as the volume compensating plunger 6 are arranged in the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com