Composite oxide, metal-supporting material and ammonia synthesis catalyst

A technology of composite oxides and oxides, which is applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, rare earth metal oxides/hydroxides, etc., and can solve problems such as insufficient ammonia yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0394] 0.5 La 0.5 o x _500℃ reduction>

[0395]

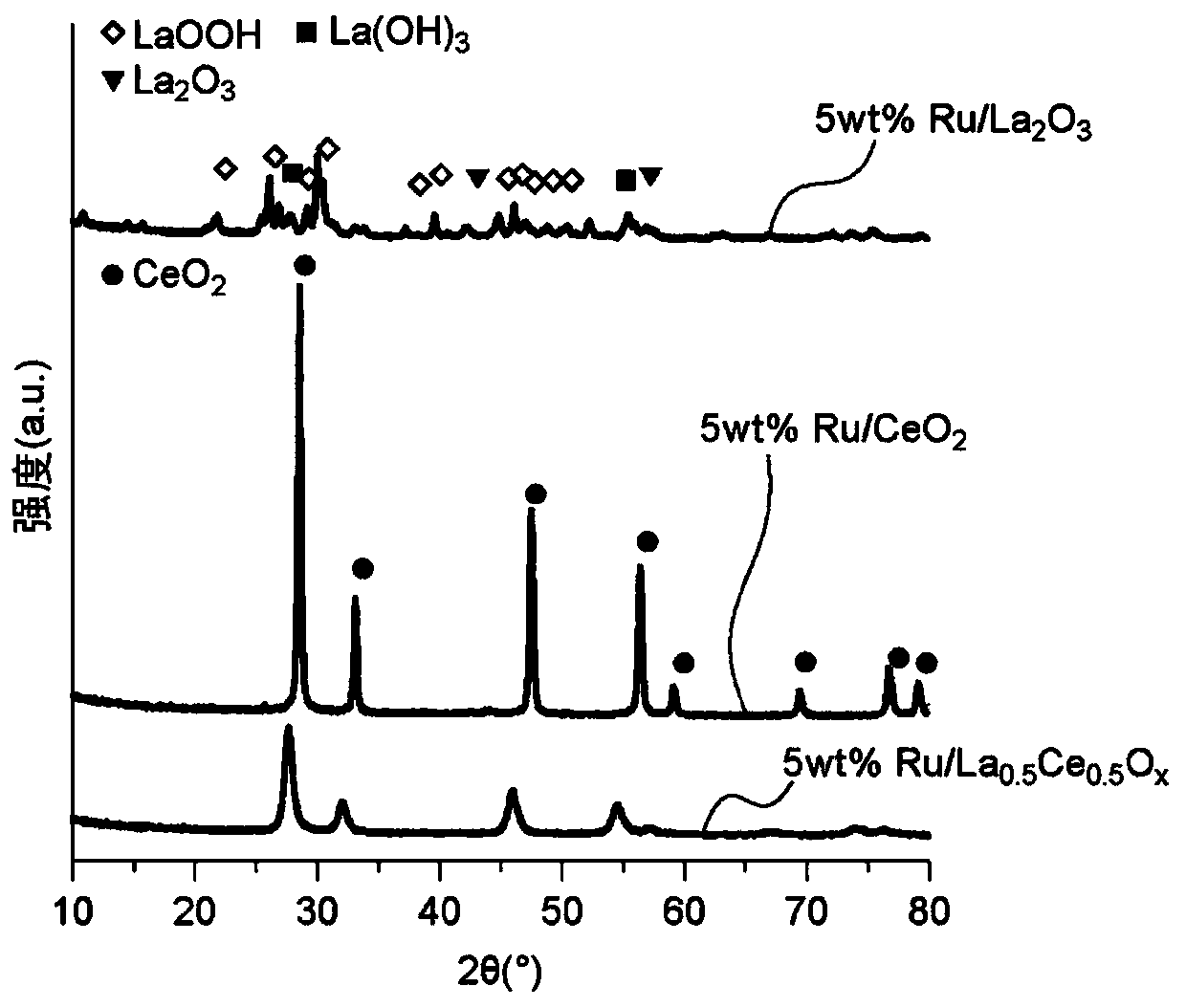

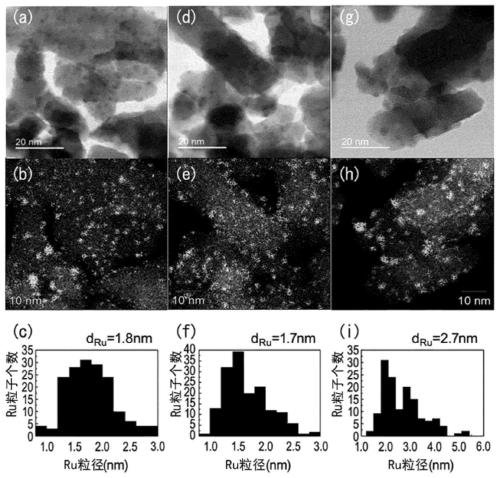

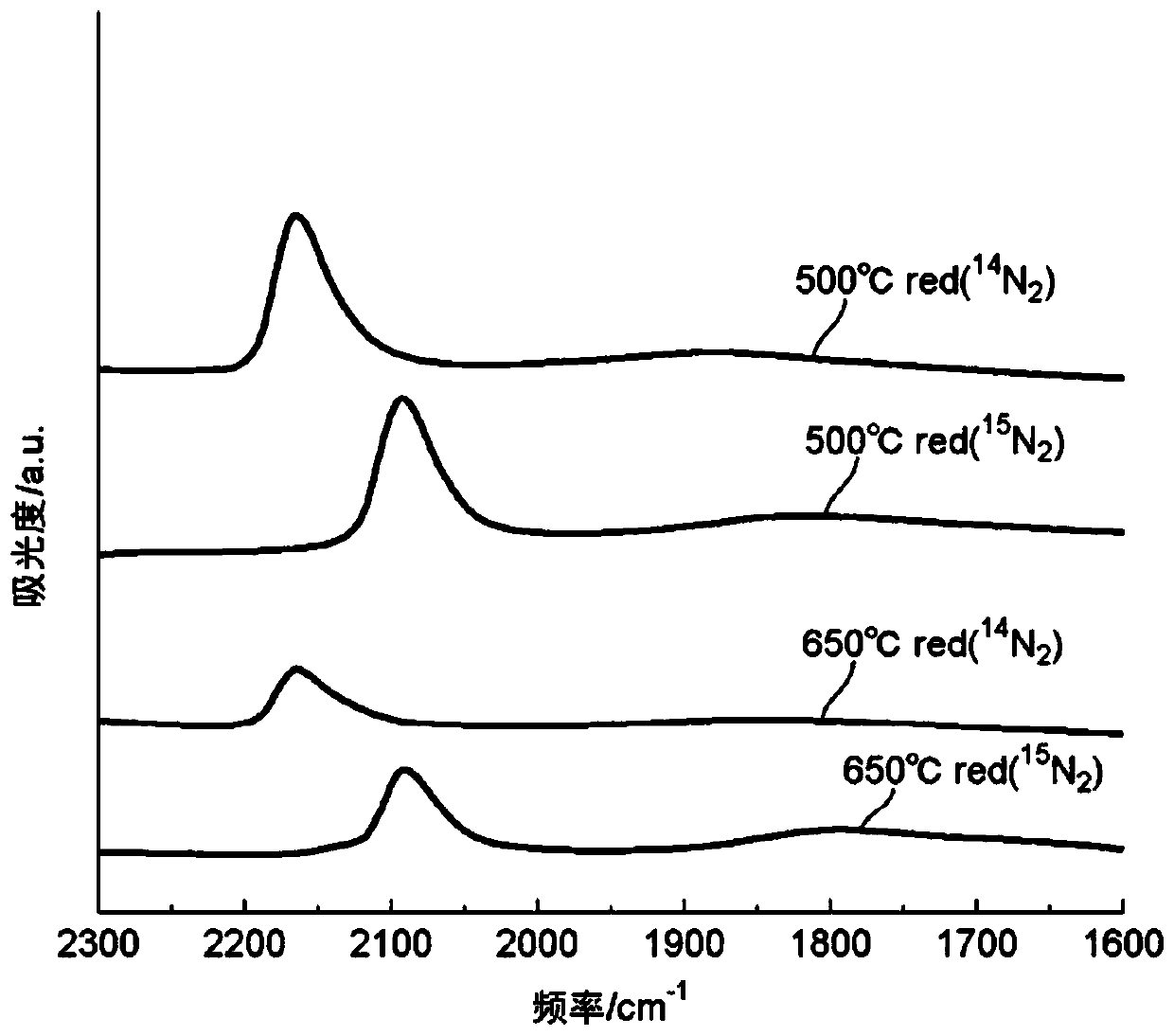

[0396] Ce 0.5 La 0.5 o x The composite oxide was synthesized as follows using the reverse homogeneous precipitation method. La(NO 3 ) 3 ·6H 2 O (Wako Pure Chemical Industries) is dissolved in purified water (Takasugi Pharmaceutical) to form La(NO 3 ) 3 aqueous solution. Ce(NO 3 ) 3 ·6H 2 O (Kanto Chemical) is dissolved in purified water to form Ce(NO 3 ) 3 aqueous solution. mixed La(NO 3 ) 3 Aqueous solution and Ce(NO 3 ) 3 As an aqueous solution, prepare 250 mL of a carrier precursor solution containing 0.0625 mol of La and Ce in total. 28% NH 3 250 mL of an aqueous solution (Wako Pure Chemical Industries, Ltd.) was added to a 1000 mL beaker, and the carrier precursor solution was added all at once while stirring at 320 rpm using a magnetic stirrer, and stirring was continued for 1 hour. Thereafter, it was left still for 30 minutes, 350 mL of the supernatant was removed, and 350 mL of ion-exchanged wate...

Embodiment 2

[0402] 0.5 La 0.5 o x _650℃ reduction>

[0403] Except that the holding temperature of the pretreatment in Example 1 was set to 650°C, the same operation as in Example 1 was carried out to obtain Ru / Ce 0.5 La 0.5 o x _650°C reduction.

Embodiment 3

[0405] 0.5 La 0.5 o x _800℃ reduction>

[0406] Except that the holding temperature of the pretreatment in Example 1 was set to 800°C, the same operation as in Example 1 was carried out to obtain Ru / Ce 0.5 La 0.5 o x _800 ℃ reduction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com